Ua puka mai nā seramika kiʻekiʻe maʻemaʻe kiʻekiʻe (SiC) ma ke ʻano he mea kūpono no nā mea koʻikoʻi i ka semiconductor, aerospace, a me nā ʻoihana kemika ma muli o kā lākou conductivity thermal kūikawā, kūpaʻa kemika, a me ka ikaika mechanical. Me ka hoʻonui ʻana i nā koi no ka hana kiʻekiʻe, haʻahaʻa haʻahaʻa pollution seramika, ka hoʻomohala ʻana i nā ʻenehana hoʻomākaukau kūpono a scalable no nā seramika SiC maʻemaʻe kiʻekiʻe ua lilo i mea noiʻi honua. Ke nānā nei kēia pepa i nā ʻano hoʻomākaukau nui o kēia manawa no nā seramika SiC maʻemaʻe kiʻekiʻe, e pili ana i ka sintering recrystallization, pressureless sintering (PS), hot pressing (HP), spark plasma sintering (SPS), a me additive manufacturing (AM), me ka manaʻo nui i ke kūkākūkā ʻana i nā mīkini sintering, nā ʻāpana kī, nā waiwai waiwai, a me nā pilikia o kēlā me kēia kaʻina hana.

ʻO ka hoʻohana ʻana i nā seramika SiC i ka pūʻali koa a me ka ʻenehana

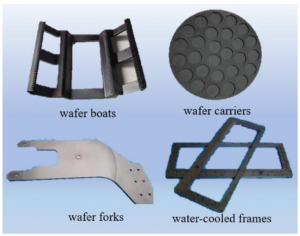

I kēia manawa, hoʻohana nui ʻia nā ʻāpana seramika SiC maʻemaʻe kiʻekiʻe i nā lako hana wafer silicon, e komo ana i nā kaʻina hana nui e like me ka oxidation, lithography, etching, a me ka implantation ion. Me ka holomua o ka ʻenehana wafer, ua lilo ka hoʻonui ʻana i ka nui wafer i mea nui. ʻO 300 mm ka nui o ka wafer nui i kēia manawa, e loaʻa ana i kahi kaulike maikaʻi ma waena o ke kumukūʻai a me ka hiki ke hana. Eia nō naʻe, i alakaʻi ʻia e ke Kānāwai a Moore, ʻo ka hana nui o nā wafers 450 mm aia ma ka papa kuhikuhi. Pono nā wafers nui i ka ikaika o ke kūkulu ʻana e pale aku i ka warping a me ka deformation, e hoʻoulu hou i ka ulu nui o ka nui, ikaika kiʻekiʻe, kiʻekiʻe-maʻemaʻe kiʻekiʻe. I nā makahiki i hala iho nei, ua hōʻike ʻia ka hana hoʻohui (3D paʻi), ma ke ʻano he ʻenehana prototyping wikiwiki e koi ʻole i nā molds, i ka mana nui i ka hana ʻana i nā ʻāpana seramika SiC paʻakikī ma muli o kona kūkulu ʻana i kēlā me kēia ʻāpana a me nā mana hoʻolālā maʻalahi, e huki ana i ka manaʻo ākea.

E kālele ana kēia pepa i ʻelima mau ʻano hoʻomākaukau hoʻomākaukau no nā seramika SiC maʻemaʻe kiʻekiʻe - ka sintering recrystallization, ka sintering ʻole, ke kaomi wela, ka sintering plasma spark, a me ka hana hoʻohui - e kālele ana i kā lākou sintering mechanical, kaʻina hana hoʻolālā, nā hiʻohiʻona hana waiwai, a me nā manaʻo noiʻi ʻoihana.

Kiʻekiʻe-maʻemaʻe silika carbide maka mea pono

I. Recrystallization Sintering

ʻO ka carbide silicon recrystallized (RSiC) kahi mea SiC maʻemaʻe kiʻekiʻe i hoʻomākaukau ʻia me ka ʻole o nā kōkua sintering i nā wela kiʻekiʻe o 2100–2500°C. Mai ka ʻike mua ʻana o Fredriksson i ka hanana recrystallization i ka hopena o ke kenekulia 19, ua loaʻa i ka RSiC ka manaʻo nui ma muli o kona mau palena palaoa maʻemaʻe a me ka nele o nā ʻāpana aniani a me nā haumia. Ma nā wela kiʻekiʻe, hōʻike ʻo SiC i ke kaomi mahu kiʻekiʻe, a ʻo kāna ʻano sintering e pili ana i kahi kaʻina evaporation-condensation: e hoʻoheheʻe ʻia nā huaʻai maikaʻi a waiho hou ma luna o ka ʻili o nā hua nui, e hoʻoikaika ana i ka ulu ʻana o ka ʻāʻī a me ka hoʻopaʻa pololei ʻana ma waena o nā kīʻaha, a laila e hoʻonui ai i ka ikaika waiwai.

I ka makahiki 1990, ua hoʻomākaukau ʻo Kriegesmann i ka RSiC me ka mānoanoa pili o 79.1% me ka hoʻohana ʻana i ka hoʻoheheʻe ʻana ma 2200°C, me ka ʻāpana keʻa e hōʻike ana i kahi microstructure i haku ʻia me nā ʻōpala a me nā pores. Ma hope mai, ʻo Yi et al. hoʻohana i ka hoʻolei gel no ka hoʻomākaukau ʻana i nā kino ʻōmaʻomaʻo a sintered iā lākou ma 2450 ° C, e loaʻa ana i nā seramika RSiC me ka nui nui o 2.53 g / cm³ a me ka ikaika flexural o 55.4 MPa.

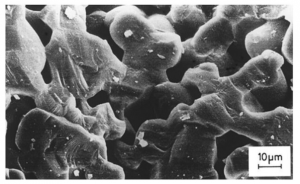

ʻO ka ili haʻi SEM o RSiC

Hoʻohālikelike ʻia me ka SiC paʻa, he haʻahaʻa haʻahaʻa ka RSiC (ma kahi o 2.5 g/cm³) a ma kahi o 20% open porosity, e kaupalena ana i kāna hana ma nā noi ikaika kiʻekiʻe. No laila, ʻo ka hoʻomaikaʻi ʻana i ka nui a me nā waiwai mechanical o RSiC ua lilo i kumu noiʻi koʻikoʻi. Sung et al. manaʻo ʻia e hoʻokomo i ka silikoni hoʻoheheʻe ʻia i loko o ka carbon/β-SiC i hui pū ʻia a me ka recrystallizing ma 2200°C, me ka holomua o ke kūkulu ʻana i kahi ʻōnaehana pūnaewele i haku ʻia me nā ʻanoʻano α-SiC. Ua loaʻa i ka RSiC ka nui o 2.7 g/cm³ a me ka ikaika flexural o 134 MPa, e mālama ana i ke kūpaʻa mechanical maikaʻi loa i nā wela kiʻekiʻe.

No ka hoʻonui ʻana i ka nui, ʻo Guo et al. hoʻohana i ka ʻenehana polymer infiltration a me ka pyrolysis (PIP) no nā lāʻau lapaʻau he nui o RSiC. Me ka hoʻohana ʻana i nā solutions PCS/xylene a me nā slurries SiC/PCS/xylene ma ke ʻano he infiltrants, ma hope o 3-6 PIP cycles, ua hoʻomaikaʻi maikaʻi ʻia ka nui o RSiC (a hiki i 2.90 g/cm³), me kona ikaika flexural. Eia kekahi, ua hoʻolālā lākou i kahi hoʻolālā cyclic e hui pū ana i ka PIP a me ka recrystallization: pyrolysis ma 1400 ° C a ukali ʻia e ka recrystallization ma 2400 ° C, e hoʻomaʻemaʻe pono i nā blockages particle a hoʻemi i ka porosity. Ua loaʻa i ka mea RSiC hope loa ka mānoanoa o 2.99 g/cm³ a me ka ikaika flexural o 162.3 MPa, e hōʻike ana i ka hana piha piha.

Nā kiʻi SEM o ka microstructure evolution o RSiC polimer ma hope o ka polymer impregnation a me ka pyrolysis (PIP) -recrystallization cycles: Initial RSiC (A), ma hope o ka mua PIP-recrystallization cycle (B), a ma hope o ke kolu o ka pōʻai (C)

II. Hoʻopaʻa paʻa ʻole

Hoʻomākaukau maʻamau nā ceramics silicon carbide (SiC) pressureless-sintered me ka hoʻohana ʻana i ka pauka SiC maʻemaʻe kiʻekiʻe ma ke ʻano he mea maka, me nā mea liʻiliʻi o nā mea kōkua sintering i hoʻohui ʻia, a hoʻopaʻa ʻia i loko o kahi ea inert a i ʻole vacuum ma 1800–2150 ° C. He kūpono kēia ʻano hana no ka hana ʻana i nā ʻāpana seramika nui a paʻakikī. Eia nō naʻe, ʻoiai ua hoʻopaʻa ʻia ʻo SiC i ka covalently coefficient, haʻahaʻa loa kona coefficient diffusion ponoʻī, e paʻakikī ana ka hoʻopaʻa ʻana me ka ʻole o nā kōkua sintering.

Ma muli o ka hana sintering, hiki ke hoʻokaʻawale ʻia ka sintering pressureless i ʻelua mau ʻāpana: pressureless liquid-phase sintering (PLS-SiC) a me pressureless solid-state sintering (PSS-SiC).

1.1 PLS-SiC (Hoʻopaʻa Wai-Phase Sintering)

Hoʻopili maʻamau ʻia ʻo PLS-SiC ma lalo o 2000°C ma ka hoʻohui ʻana ma kahi o 10 wt.% o nā mea kōkua sintering eutectic (e like me Al₂O₃, CaO, MgO, TiO₂, a me nā oxides rare-earth oxides RE₂O₃) e hoʻokō ai i kahi pae wai, e hoʻoikaika ana i ka hoʻololi ʻana o nā ʻāpana. He kūpono kēia kaʻina hana no nā seramika SiC kiʻekiʻe ʻoihana, akā ʻaʻohe hōʻike o ka SiC maʻemaʻe kiʻekiʻe i loaʻa ma o ka sintering wai.

1.2 PSS-SiC (Sintering State Paʻa)

Hoʻokomo ka PSS-SiC i ka densification solid-state ma nā mahana ma luna o 2000 ° C me kahi 1 wt.% o nā mea hoʻohui. Ke hilinaʻi nui nei kēia kaʻina hana i ka diffusion atomic a me ka hoʻonohonoho hou ʻana o ka palaoa i alakaʻi ʻia e nā wela kiʻekiʻe e hōʻemi i ka ikehu o ka ʻili a loaʻa ka densification. ʻO ka ʻōnaehana BC (boron-carbon) he hui hoʻohui maʻamau, hiki ke hoʻohaʻahaʻa i ka ikehu palena o ka palaoa a hoʻoneʻe iā SiO₂ mai ka ʻili SiC. Eia naʻe, hoʻokomo pinepine nā mea hoʻohui BC kahiko i nā koena haumia, e hōʻemi ana i ka maʻemaʻe SiC.

Ma ka hoʻomaluʻana i nā mea hoʻohui (B 0.4 wt.%, C 1.8 wt.%) a me ka sintering ma 2150 ° C no nā hola 0.5, loaʻa nā seramika SiC maʻemaʻe kiʻekiʻe me ka maʻemaʻe o 99.6 wt.% a me kahi pili pili o 98.4%. Ua hōʻike ʻia ka microstructure i nā ʻōpala kolamu (ʻoi aʻe kekahi ma mua o 450 µm ka lōʻihi), me nā pores liʻiliʻi ma nā palena o ka palaoa a me nā ʻāpana graphite i loko o nā kīʻaha. Ua hōʻike nā seramika i ka ikaika flexural o 443 ± 27 MPa, kahi modulus elastic o 420 ± 1 GPa, a me kahi koena hoʻonui wela o 3.84 × 10⁻⁶ K⁻¹ ma ka laulā o ka lumi wela a hiki i 600 ° C, e hōʻike ana i ka hana holoʻokoʻa maikaʻi loa.

Microstructure o PSS-SiC: (A) kiʻi SEM ma hope o ka poli a me NaOH etching; (BD) Nā kiʻi BSD ma hope o ka hoʻoliʻi ʻana a me ke kālai ʻana

III. Hoʻopaʻa Paʻi Wela

ʻO ka sintering wela (HP) kahi ʻenehana hoʻopaʻa i ka manawa like e pili ana i ka wela a me ke kaomi uniaxial i nā mea pauka ma lalo o nā kūlana kiʻekiʻe a me nā kūlana kiʻekiʻe. Kāohi nui ke kaomi kiʻekiʻe i ka hoʻokumu ʻana o ka pore a hoʻopaʻa i ka ulu ʻana o ka palaoa, ʻoiai ke kiʻekiʻe ka wela e hoʻoikaika i ka hui ʻana o ka palaoa a me ka hoʻokumu ʻana i nā hale paʻa, i ka hopena e hana i nā seramika SiC maʻemaʻe kiʻekiʻe. Ma muli o ke ʻano alakaʻi o ke kaomi ʻana, ʻo kēia kaʻina hana e hoʻoulu i ka anisotropy palaoa, e pili ana i ka mīkini a me nā waiwai.

He mea paʻakikī ke hoʻopaʻa ʻana i nā seramika SiC maʻemaʻe me ka ʻole o nā mea hoʻohui, e koi ana i ka sintering ultrahigh-pressure. Nadeau et al. ua hoʻomākaukau maikaʻi ʻia ʻo SiC paʻa loa me ka ʻole o nā mea hoʻohui ma 2500°C a me 5000 MPa; ʻO Sun et al. loaʻa nā mea nui β-SiC me ka paʻakikī Vickers a hiki i 41.5 GPa ma 25 GPa a me 1400 ° C. Me ka hoʻohana ʻana i ke kaomi 4 GPa, ua hoʻomākaukau ʻia nā seramika SiC me nā density pili ma kahi o 98% a me 99%, ka paʻakikī o 35 GPa, a me ka modulus elastic o 450 GPa i hoʻomākaukau ʻia ma 1500°C a me 1900°C. ʻO ka Sintering micron-sized SiC pauka ma 5 GPa a me 1500 ° C i hāʻawi mai i nā seramika me ka paʻakikī o 31.3 GPa a me kahi pili pili o 98.4%.

ʻOiai ke hōʻike nei kēia mau hopena i hiki i ke kaomi ultrahigh ke hoʻokō i ka densification ʻole additive, ʻo ka paʻakikī a me ke kumukūʻai kiʻekiʻe o nā mea pono e kaupalena ʻia nā noi ʻoihana. No laila, i ka hoʻomākaukau pono ʻana, hoʻohana pinepine ʻia nā trace additives a i ʻole ka pauka granulation e hoʻomaikaʻi i ka ikaika hoʻokele sintering.

Ma ka hoʻohui ʻana i ka 4 wt.% phenolic resin ma ke ʻano he additive a me ka sintering ma 2350 ° C a me 50 MPa, ua loaʻa nā ceramics SiC me ka densification rate o 92% a me ka maʻemaʻe o 99.998%. Ke hoʻohana nei i nā mea hoʻohui haʻahaʻa (boric acid a me D-fructose) a me ka sintering ma 2050 ° C a me 40 MPa, hoʻomaʻemaʻe kiʻekiʻe ʻo SiC me kahi pili pili> 99.5% a me ke koena B maʻiʻo o 556 ppm wale nō i mākaukau. Hōʻike nā kiʻi SEM, i ka hoʻohālikelike ʻia me nā laʻana i hoʻopaʻa ʻia me ka pressureless-sintered, ʻoi aku ka liʻiliʻi o nā ʻāpana wela, nā pores liʻiliʻi, a me ke kiʻekiʻe kiʻekiʻe. ʻO ka ikaika flexural he 453.7 ± 44.9 MPa, a hiki i ka modulus elastic i 444.3 ± 1.1 GPa.

Ma ka hoʻolōʻihi ʻana i ka manawa paʻa ma 1900 ° C, ua hoʻonui ʻia ka nui o ka palaoa mai 1.5 μm a i 1.8 μm, a ua hoʻomaikaʻi ʻia ka conductivity thermal mai 155 a i 167 W·m⁻¹·K⁻¹, me ka hoʻonui ʻana i ka pale ʻana i ka corrosion plasma.

Ma lalo o nā kūlana o 1850 ° C a me 30 MPa, kaomi wela a me ka wikiwiki wela o ka granulated a me ka annealed SiC pauka i hāʻawi ʻia i nā ceramics β-SiC piha piha me ka ʻole o nā mea hoʻohui, me ka density o 3.2 g / cm³ a me kahi mahana sintering 150-200 ° C haʻahaʻa ma mua o nā hana kuʻuna. Ua hōʻike nā seramika i ka paʻakikī o 2729 GPa, ʻo ka paʻakikī haʻihaʻi o 5.25–5.30 MPa·m^1/2, a me ke kūpaʻa kolo maikaʻi loa (nā helu kolo o 9.9 × 10⁻¹⁰ s⁻¹ a me 3.8 × 10⁻⁹°C ma ⁻⁹ °C ⁻⁹ °C. 100 MPa).

(A) kiʻi SEM o ka ʻili i poni ʻia; (B) kiʻi SEM o ka ʻili haki; (C, D) BSD kiʻi o ka ʻili i poni ʻia

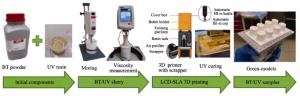

I ka noiʻi paʻi 3D no nā ceramics piezoelectric, slurry ceramic, ʻo ia ke kumu kumu e hoʻohuli ai i ka hoʻokumu ʻana a me ka hana ʻana, ua lilo ia i mea koʻikoʻi ma ka home a me ka honua. Hōʻike maʻamau nā haʻawina i kēia manawa e pili ana nā ʻāpana e like me ka nui o ka pauka, ka slurry viscosity, a me ka ʻike paʻa i ka hopena maikaʻi a me nā waiwai piezoelectric o ka huahana hope.

Ua ʻike ka noiʻi ua hoʻomākaukau ʻia nā slurries seramika me ka micron-, submicron-, a me ka nano-sized barium titanate powders e hōʻike ana i nā ʻokoʻa koʻikoʻi i nā kaʻina stereolithography (e laʻa, LCD-SLA). Ke emi nei ka nui o ka ʻāpana, piʻi nui ka slurry viscosity, me ka nano-sized powders e hana ana i nā slurries me nā viscosities a hiki i nā piliona mPa·s. Hiki i nā ʻōpala me nā pauka nui micron i ka delamination a me ka ʻili ʻana i ka wā o ka paʻi ʻana, ʻoiai nā pauka submicron a me nā nano-sized e hōʻike ana i ke ʻano paʻa. Ma hope o ka sintering wela kiʻekiʻe, ua loaʻa i nā laʻana seramika ka nui o 5.44 g/cm³, kahi piezoelectric coefficient (d₃₃) ma kahi o 200 pC/N, a me nā kumu poho haʻahaʻa, e hōʻike ana i nā waiwai pane electromechanical maikaʻi loa.

Eia hou, ma nā kaʻina hana micro-stereolithography, hoʻoponopono i ka ʻike paʻa o nā slurries PZT-type (e laʻa, 75 wt.%) i hāʻawi i nā kino sintered me ka density o 7.35 g/cm³, e loaʻa ana i ka piezoelectric mau a hiki i 600 pC/N ma lalo o nā māla uila. ʻO ka noiʻi e pili ana i ka micro-scale deformation uku i hoʻomaikaʻi nui ʻia i ka hoʻokumu ʻana i ka pololei, hoʻonui i ka pololei geometric a hiki i ka 80%.

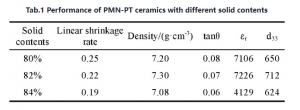

Ua hōʻike ʻia kahi noiʻi ʻē aʻe ma PMN-PT piezoelectric ceramics e pili ana ka maʻiʻo paʻa i ka hoʻololi koʻikoʻi i ka hana keramika a me nā waiwai uila. Ma 80 wt.% maʻiʻo paʻa, ʻike maʻalahi nā huahana i loko o nā seramika; i ka piʻi ʻana o ka maʻiʻo paʻa i ka 82 wt.% a ma luna aʻe, ua nalowale nā huahana, a ua ʻoi aku ka maʻemaʻe o ka hale ceramic, me ka hoʻomaikaʻi nui ʻana i ka hana. Ma ka 82 wt.%, ua hōʻike nā seramika i nā waiwai uila maikaʻi loa: kahi piezoelectric mau o 730 pC/N, pili i ka permittivity o 7226, a me ka nalowale dielectric o 0.07 wale nō.

I ka hōʻuluʻulu ʻana, ʻaʻole pili wale ka nui o ka ʻāpana, ka ʻike paʻa, a me nā waiwai rheological o nā slurries seramika i ka paʻa a me ka pololei o ke kaʻina paʻi akā e hoʻoholo pololei i ka nui a me ka pane piezoelectric o nā kino sintered, e hoʻolilo iā lākou i nā ʻāpana kiʻekiʻe no ka hoʻokō ʻana i nā seramika piezoelectric kiʻekiʻe.

ʻO ke kaʻina hana nui o ka paʻi LCD-SLA 3D o nā mea hoʻohālike BT / UV

ʻO nā waiwai o nā seramika PMN-PT me nā mea paʻa like ʻole

IV. Spark Plasma Sintering

ʻO Spark plasma sintering (SPS) kahi ʻenehana sintering kiʻekiʻe e hoʻohana ana i ka pulsed o kēia manawa a me ke kaomi mechanical i ka manawa like i hoʻopili ʻia i nā pauka e hoʻokō i ka densification wikiwiki. Ma kēia kaʻina hana, hoʻomaʻamaʻa pololei kēia manawa i ka ʻōpala a me ka pauka, e hana ana i ka wela Joule a me ka plasma, e hiki ai i ka sintering maikaʻi i ka manawa pōkole (maʻamau i loko o 10 mau minuke). Hoʻoikaika ka hoʻomehana wikiwiki i ka laha ʻana o ka ʻili, ʻoiai ʻo ka hoʻokuʻu ʻana i ke ahi e kōkua i ka hoʻoneʻe ʻana i nā kinoea adsorbed a me nā ʻāpana oxide mai nā papa lepo, e hoʻomaikaʻi ana i ka hana sintering. ʻO ka hopena electromigration i hoʻoulu ʻia e nā māla electromagnetic e hoʻonui i ka diffusion atomic.

Ke hoʻohālikelike ʻia me ke kaomi wela kuʻuna, hoʻohana ʻo SPS i ka hoʻomehana pololei, hiki ke hoʻopaʻa ʻia i nā haʻahaʻa haʻahaʻa ʻoiai ke kāohi pono nei i ka ulu ʻana o ka palaoa e loaʻa ai nā microstructures maikaʻi a kūlike. ʻo kahi laʻana:

- Me ka ʻole o nā mea hoʻohui, e hoʻohana ana i ka lepo SiC pauka e like me ka mea maka, sintering ma 2100 ° C a me 70 MPa no nā minuke 30 i hāʻawi ʻia i nā laʻana me 98% pili pili.

- ʻO ka Sintering ma 1700 ° C a me 40 MPa no 10 mau minuke i hoʻopuka i ka SiC cubic me ka 98% density a me ka nui o ka palaoa o 30-50 nm wale nō.

- ʻO ka hoʻohana ʻana i ka pauka SiC granular 80 µm a me ka sintering ma 1860 ° C a me 50 MPa no nā minuke 5 i hopena i nā ceramics SiC kiʻekiʻe me 98.5% pili pili, Vickers microhardness o 28.5 GPa, ikaika flexural o 395 MPa, a me ka paʻakikī o ka haʻihaʻi o 4.5/MPa.

Ua hōʻike ʻia ka loiloi microstructural i ka piʻi ʻana o ka mahana sintering mai 1600 ° C a i 1860 ° C, ua emi nui ka porosity material, e hoʻokokoke ana i ka piha piha i nā wela kiʻekiʻe.

Hoʻopili ʻia ka microstructure o nā ceramics SiC i nā wela like ʻole: (A) 1600°C, (B) 1700°C, (C) 1790°C a me (D) 1860°C

V. Hana Hoohui

Ua hōʻike ʻo Additive Manufacturing (AM) i ka mana nui i ka hana ʻana i nā ʻāpana seramika paʻakikī ma muli o kāna kaʻina hana papa-by-layer. No nā seramika SiC, ua hoʻomohala ʻia nā ʻenehana AM he nui, me ka binder jetting (BJ), 3DP, selective laser sintering (SLS), direct ink writing (DIW), a me stereolithography (SL, DLP). Eia nō naʻe, ʻo 3DP a me DIW ka haʻahaʻa haʻahaʻa, ʻoiai ʻo SLS ka mea e hoʻoulu ai i ke kaumaha wela a me nā māwae. ʻO ka ʻokoʻa, hāʻawi ʻo BJ a me SL i nā mea maikaʻi loa i ka hana ʻana i nā seramika paʻakikī kiʻekiʻe-maʻemaʻe.

- Hoʻopaʻa Paʻa (BJ)

Hoʻokomo ʻia ka ʻenehana BJ i ka hoʻopuʻi ʻana o ka mea hoʻopili i ka pauka paʻa, a ukali ʻia e ka debinding a me ka sintering e loaʻa ai ka huahana keramika hope loa. ʻO ka hoʻohui ʻana i ka BJ me ka infiltration chemical vapor infiltration (CVI), kiʻekiʻe-maʻemaʻe, piha crystalline SiC ceramics ua mākaukau maikaʻi. Aia ke kaʻina hana:

① Ka hana ʻana i nā kino ʻōmaʻomaʻo seramika SiC me ka hoʻohana ʻana iā BJ.

② Hoʻopaʻa ʻia ma o CVI ma 1000°C a me 200 Torr.

③ He 2.95 g/cm³ ka mānoanoa SiC hope loa, he 37 W/m·K, a me ka ikaika flexural o 297 MPa.

Kiʻikuhi kiʻi o ka paʻi jet adhesive (BJ). (A) Ke kumu hoʻolālā kōkua kamepiula (CAD), (B) kiʻi kiʻi kiʻi o ke kumu BJ, (C) paʻi ʻana o SiC e BJ, (D) hoʻopaʻapaʻa ʻana o SiC ma o ke komo ʻana o ka mahu mahu (CVI)

- ʻO ke kiʻi ʻoniʻoni (SL)

ʻO SL kahi ʻenehana hoʻoheheʻe ʻana i ka UV-curing-based me ka pololei kiʻekiʻe loa a me ka hiki ke hana i ka hana paʻakikī. Ke hoʻohana nei kēia ʻano hana i nā slurries ceramic photosensitive me ka ʻike paʻa kiʻekiʻe a me ka viscosity haʻahaʻa e hana i nā kino ʻōmaʻomaʻo 3D ceramic ma o ka photopolymerization, a ukali ʻia e ka debinding a me ka sintering wela kiʻekiʻe e loaʻa ai ka huahana hope.

Ke hoʻohana nei i kahi slurry 35 vol.% SiC, ua hoʻomākaukau ʻia nā kino ʻōmaʻomaʻo 3D kiʻekiʻe ma lalo o 405 nm UV irradiation a hoʻonui hou ʻia ma o ka polymer burnout ma 800 ° C a me ka mālama PIP. Ua hōʻike nā hualoaʻa i nā laʻana i hoʻomākaukau ʻia me 35 vol.% slurry i loaʻa i kahi pili pili o 84.8%, ma mua o 30% a me 40% mau pūʻulu mana.

Ma ka hoʻokomo ʻana i ka lipophilic SiO₂ a me ka phenolic epoxy resin (PEA) e hoʻololi i ka slurry, ua hoʻomaikaʻi maikaʻi ʻia ka hana photopolymerization. Ma hope o ka sintering ma 1600 ° C no 4 mau hola, ua hoʻokō ʻia ka hoʻololi ʻana kokoke i ka SiC, me ka maʻi oxygen hope o 0.12% wale nō, hiki ke hana i hoʻokahi-ʻanuʻu o nā seramika SiC maʻemaʻe kiʻekiʻe, paʻakikī-kūkulu ʻole me ka pre-oxidation a i ʻole pre-infiltration.

Hoʻohālikelike o ke ʻano paʻi a me kāna hana sintering. ʻO ke ʻano o ka hāpana ma hope o ka maloʻo ʻana ma (A) 25°C, pyrolysis ma (B) 1000°C, a me ka sintering ma (C) 1600°C.

Ma ka hoʻolālā ʻana i nā slurries ceramic photosensitive Si₃N₄ no ka paʻi stereolithography 3D a me ka hoʻohana ʻana i nā kaʻina hana debinding-prestering a me ka wela wela kiʻekiʻe, ua mākaukau ʻo Si₃N₄ ceramics me 93.3% theoretical density, ikaika tensile o 279.8 MPa, a me ka ikaika flexural o 3338.5 MPa. Ua ʻike nā haʻawina ma lalo o nā kūlana o 45 vol.% solid content a me 10 s ka manawa hoʻolaha, hiki ke loaʻa nā kino ʻōmaʻomaʻo hoʻokahi me ka IT77-level curing precision. Ua kōkua ke kaʻina hana hoʻopaʻa haʻahaʻa haʻahaʻa me ka laiki wela o 0.1 °C/min i ka hana ʻana i nā kino ʻōmaʻomaʻo ʻole.

ʻO ka Sintering kahi hana koʻikoʻi e pili ana i ka hana hope ma stereolithography. Hōʻike nā noiʻi ʻo ka hoʻohui ʻana i nā mea kōkua sintering hiki ke hoʻomaikaʻi maikaʻi i ka nui o ka keramika a me nā waiwai mechanical. Ke hoʻohana nei i ka CeO₂ ma ke ʻano he kōkua sintering a me ka ʻenehana hoʻoheheʻe ʻana i ke kahua uila no ka hoʻomākaukau ʻana i nā ceramics Si₃N₄ kiʻekiʻe kiʻekiʻe, ua ʻike ʻia ʻo CeO₂ e hoʻokaʻawale i nā palena o ka palaoa, e hāpai ana i ka hoʻoheheʻe ʻana o ka palena palaoa a me ka densification. Ua hōʻike ʻia nā seramika i loaʻa iā Vickers paʻakikī o HV10/10 (1347.9 ± 2.4) a me ka paʻakikī haʻihaʻi o (6.57 ± 0.07) MPa·m¹/². Me ka MgO–Y₂O₃ ma ke ʻano he mea hoʻohui, ua hoʻomaikaʻi ʻia ka homogeneity microstructure ceramic, hoʻonui nui i ka hana. Ma ka huina doping pae o 8 wt.%, flexural ikaika a me thermal conductivity hiki i 915.54 MPa a me 59.58 W·m⁻¹·K⁻¹, pākahi.

VI. Ka hopena

I ka hōʻuluʻulu ʻana, ua hōʻike nā ceramics silicon carbide (SiC) kiʻekiʻe, ma ke ʻano he ʻenehana seramika koʻikoʻi, ua hōʻike i nā manaʻo noiʻi ākea i nā semiconductor, aerospace, a me nā lako kūlana kiʻekiʻe. Ua kālailai ʻōnaehana kēia pepa i ʻelima mau ala hoʻomākaukau maʻamau no nā seramika SiC maʻemaʻe kiʻekiʻe - ka hoʻoheheʻe ʻana i ka hoʻoheheʻe ʻana, ka sintering ʻole, ka paʻi wela, ka sintering plasma spark, a me ka hana hoʻohui - me nā kūkākūkā kikoʻī e pili ana i kā lākou densification mechanical, key parameter optimization, material performance, a me nā pono a me nā palena.

ʻIke ʻia ka loaʻa ʻana o nā ʻano hana like ʻole i kēlā me kēia me ka loaʻa ʻana o ka maʻemaʻe kiʻekiʻe, ke kiʻekiʻe kiʻekiʻe, nā hale paʻakikī, a me ka hiki ke hana. ʻO ka ʻenehana hana hoʻohui, ʻo ia hoʻi, ua hōʻike i ka mana ikaika i ka hana ʻana i nā ʻāpana paʻakikī a me nā mea i hoʻopilikino ʻia, me nā holomua i nā subfields e like me stereolithography a me ka binder jetting, e lilo ia i alakaʻi hoʻomohala koʻikoʻi no ka hoʻomākaukau kiʻekiʻe SiC keramika.

Pono e noiʻi i ka wā e hiki mai ana i ka hoʻomākaukau ʻana i ka ceramic maʻemaʻe kiʻekiʻe, e hoʻoikaika ana i ka hoʻololi ʻana mai ke keʻena ʻoihana a hiki i nā noi ʻenehana hilinaʻi nui, a laila e hāʻawi i ke kākoʻo koʻikoʻi no ka hana ʻana i nā mea hana kiʻekiʻe a me nā ʻenehana ʻike o ka hanauna e hiki mai ana.

He ʻoihana ʻenehana kiʻekiʻe ʻo XKH i ka noiʻi a me ka hana ʻana i nā mea seramika kiʻekiʻe. Hoʻolaʻa ʻia i ka hāʻawi ʻana i nā hoʻonā maʻamau no nā mea kūʻai aku ma ke ʻano o ka silicon carbide (SiC) ceramics kiʻekiʻe. Loaʻa i ka hui nā ʻenehana hoʻomākaukau waiwai a me nā hiki ke hana pololei. Hoʻopili ʻia kāna ʻoihana i ka noiʻi, hana, hoʻoponopono pololei, a me ka mālama ʻana i ka ʻili o nā seramika SiC maʻemaʻe kiʻekiʻe, e hālāwai ana i nā koi koʻikoʻi o semiconductor, ikehu hou, aerospace a me nā māla ʻē aʻe no nā ʻāpana seramika kiʻekiʻe. Ke hoʻohana nei i nā kaʻina hana sintering makua a me nā ʻenehana hana hoʻohui, hiki iā mākou ke hāʻawi aku i nā mea kūʻai aku i kahi lawelawe hoʻokahi mai ka hoʻoponopono ʻana i nā kumu waiwai, ka hoʻokumu ʻana i ka hana paʻakikī i ka hoʻoponopono pololei ʻana, e hōʻoiaʻiʻo ana i nā huahana i loaʻa nā waiwai mechanical maikaʻi loa, kūpaʻa wela a me ka pale ʻana i ka corrosion.

Ka manawa hoʻouna: Iulai-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)