Nīnau: He aha nā ʻenehana nui i hoʻohana ʻia i ka SiC wafer slicing a me ka hana?

A:Silicon carbide (SiC) ka lua o ka paakiki ma mua o ke daimana a ua manaoia he mea paakiki loa. ʻO ke kaʻina hana ʻoki, ʻo ia hoʻi ka ʻoki ʻana i nā kristal i ulu i loko o nā wafers lahilahi, ʻoi aku ka lōʻihi o ka manawa a hiki ke ʻoki ʻia. E like me ka hana mua i lokoSiCʻO ka hana aniani hoʻokahi, ʻo ka maikaʻi o ka ʻoki ʻana e hoʻoikaika nui i ka wili ʻana, polishing, a me ka lahilahi. Hoʻokomo pinepine ʻia ka ʻoki ʻana i nā māwae ʻili a me lalo o ka ʻāina, e hoʻonui ana i ka haki ʻana o ka wafer a me nā kumukūʻai hana. No laila, ʻo ka hoʻomalu ʻana i ka pōʻino o ka ʻili i ka wā o ka ʻoki ʻana he mea koʻikoʻi ia i ka holomua ʻana i ka hana ʻana o ka mea hana SiC.

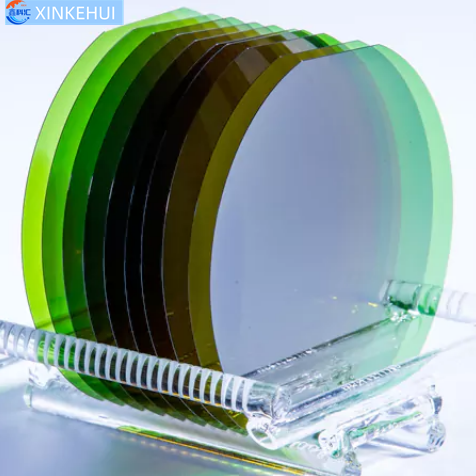

Ua hōʻike ʻia i kēia manawa nā ʻano hana ʻoki SiC e pili ana i ka paʻa-abrasive, manuahi-abrasive slicing, ka ʻoki laser, ka hoʻololi ʻana o ka papa (ka hoʻokaʻawale anuanu), a me ka ʻoki ʻana i ka uila. Ma waena o kēia mau mea, ʻo ka hoʻihoʻi ʻana i ka ʻoki ʻana i nā uea he nui me nā abrasive daimana paʻa ke ʻano maʻamau i hoʻohana ʻia no ka hana ʻana i nā kristal hoʻokahi SiC. Eia nō naʻe, ʻoiai ka nui o ka ingot a hiki i ka 8 iniha a ma luna, ua emi ka hana ʻana o ka uea kuʻuna ma muli o nā koi kiʻekiʻe o nā lako, nā koina, a me ka haʻahaʻa haʻahaʻa. Loaʻa ka makemake wikiwiki no nā kumu kūʻai haʻahaʻa, haʻahaʻa haʻahaʻa, kiʻekiʻe-efficiency slicing technology.

Q: He aha nā mea maikaʻi o ka ʻoki ʻana i ka laser ma mua o ka ʻoki ʻana i nā uea lehulehu?

A: ʻoki ʻia ka ʻili uea kuʻuna i kaSiC ingotma kahi kuhikuhi kikoʻī i loko o nā ʻāpana he mau haneli microns mānoanoa. Hoʻopili ʻia nā ʻāpana me ka hoʻohana ʻana i nā slurries daimana e wehe i nā hōʻailona ʻike a me nā pōʻino o lalo, a ukali ʻia e ka chemical mechanical polishing (CMP) e hoʻokō i ka hoʻolālā honua, a ma hope e hoʻomaʻemaʻe ʻia e loaʻa nā wafers SiC.

Eia nō naʻe, ma muli o ke kiʻekiʻe o ka paʻakikī a me ka palupalu o SiC, hiki i kēia mau ʻanuʻu ke hoʻoulu maʻalahi i ka warping, cracking, piʻi ʻana o ka haki ʻana, nā kumukūʻai kiʻekiʻe o ka hana ʻana, a me ka hopena o ka ʻeleʻele a me ka haumia (lepo, wai ʻino, etc.). Eia kekahi, ua lohi ka wili uea a haʻahaʻa ka hua. Hōʻike nā manaʻo i ka hoʻohana ʻana i nā mea hana ma kahi o 50% wale nō, a hiki i ka 75% o ka mea i nalowale ma hope o ka poli a me ka wili ʻana. Ua hōʻike ʻia ka ʻikepili hana mua o nā ʻāina ʻē he 273 mau lā o ka hana mau ʻana i 24-hola e hana ai i 10,000 wafers—ʻoi loa ka manawa.

Ma ka home, nui nā ʻoihana ulu kristal SiC e kālele ana i ka hoʻonui ʻana i ka mana o ka umu. Eia nō naʻe, ma kahi o ka hoʻonui wale ʻana i nā huahana, ʻoi aku ka nui o ka noʻonoʻo pehea e hōʻemi ai i nā poho— ʻoi aku ka maikaʻi o ka ulu ʻana o ka kristal.

Hiki i nā mea hana ʻoki laser ke hōʻemi nui i ka nalowale waiwai a hoʻomaikaʻi i ka hua. No ka laʻana, me ka hoʻohana ʻana i kahi 20 mm hoʻokahiSiC ingot: Uea sawing hiki ke hua ma kahi o 30 wafers o 350 μm mānoanoa. Laser slicing hiki ke hua mai oi aku mamua o 50 wafers. Ina wafer mānoanoa i hoemi i 200 μm, oi aku mamua o 80 wafers hiki ke hana mai ka like ingot.While uea sawing ua hoʻohana nui ia no ka wafers liʻiliʻi 6 inches, 8 inches. e lawe i nā lā 10-15 me nāʻano kuʻuna, e koi ana i nā mea hana kiʻekiʻe a me ka hoʻonuiʻana i nā kumukūʻai me ka haʻahaʻa haʻahaʻa. Ma lalo o kēia mau kūlana, ʻike maopopo ʻia nā pōmaikaʻi o ka ʻoki ʻana i ka laser, e lilo ia i ʻenehana nui e hiki mai ana no nā wafers 8-inihi.

Me ka ʻoki ʻana i ka laser, hiki ke ʻoki ʻia ka manawa ʻoki no ka wafer 8-inch ma lalo o 20 mau minuke, me ka poho waiwai no ka wafer ma lalo o 60 μm.

I ka hōʻuluʻulu ʻana, i hoʻohālikelike ʻia me ka ʻoki ʻana i nā uea he nui, hāʻawi ka ʻoki ʻana i ka laser i ka wikiwiki kiʻekiʻe, ʻoi aku ka maikaʻi o ka hoʻoulu ʻana, haʻahaʻa haʻahaʻa haʻahaʻa, a me ka hoʻomaʻemaʻe ʻana.

Nīnau: He aha nā pilikia ʻenehana nui i ka ʻoki ʻana i ka laser SiC?

A: ʻO ke kaʻina hana ʻokiʻoki laser e pili ana i ʻelua mau ʻanuʻu nui: hoʻololi laser a me ka hoʻokaʻawale wafer.

ʻO ke kumu o ka hoʻololi ʻana i ka laser ʻo ka hana ʻana i ka beam a me ka hoʻonui ʻana i nā parameter. ʻO nā ʻāpana e like me ka mana laser, ke anawaena kiko, a me ka wikiwiki scan e pili ana i ka maikaʻi o ka ablation mea a me ka kūleʻa o ka hoʻokaʻawale wafer ma hope. ʻO ka geometry o ka ʻāpana i hoʻololi ʻia e hoʻoholo i ke ʻano o ka ʻili a me ka paʻakikī o ka hoʻokaʻawale ʻana. ʻO ka ʻeleʻele ʻili kiʻekiʻe e paʻakikī i ka wili ʻana ma hope a hoʻonui i ka poho waiwai.

Ma hope o ka hoʻololi ʻana, loaʻa maʻamau ka hoʻokaʻawale ʻana o ka wafer ma o nā ikaika shear, e like me ka haki anu a i ʻole ke koʻikoʻi mechanical. Hoʻohana kekahi mau ʻōnaehana kūloko i nā transducers kani ultrasonic e hoʻoulu i nā haʻalulu no ka hoʻokaʻawale ʻana, akā hiki i kēia ke kumu i ka ʻokiʻoki a me nā kīnā ʻole, e hoʻohaʻahaʻa i ka hopena hope.

ʻOiai ʻaʻole paʻakikī kēia mau ʻanuʻu ʻelua, ʻo ka like ʻole o ka maikaʻi aniani-ma muli o nā kaʻina ulu like ʻole, nā pae doping, a me nā puʻupuʻu koʻikoʻi o loko-e pili nui i ka paʻakikī o ka ʻoki ʻana, ka hua, a me ka poho waiwai. ʻO ka ʻike wale ʻana i nā wahi pilikia a me ka hoʻoponopono ʻana i nā zona scanning laser ʻaʻole hiki ke hoʻomaikaʻi nui i nā hopena.

ʻO ke kī o ka hoʻohana ākea ʻana aia i ka hoʻomohala ʻana i nā ʻano hana hou a me nā mea hana e hiki ke hoʻololi i kahi ākea o nā ʻano kristal mai nā mea hana like ʻole, ka hoʻonui ʻana i nā ʻāpana kaʻina hana, a me ke kūkulu ʻana i nā ʻōnaehana slicing laser me ka hoʻohana āpau.

Nīnau: Hiki ke hoʻohana ʻia ka ʻenehana ʻokiʻoki laser i nā mea semiconductor ʻē aʻe ma waho o SiC?

A: Ua hoʻohana ʻia ka ʻenehana ʻokiʻoki laser i nā ʻano mea like ʻole. I nā semiconductor, ua hoʻohana mua ʻia no ka wafer dicing a ua hoʻonui ʻia i ka ʻoki ʻana i nā kristal nui nui.

Ma waho aʻe o SiC, hiki ke hoʻohana ʻia ka ʻoki ʻoki laser no nā mea paʻakikī ʻē aʻe e like me ke daimana, gallium nitride (GaN), a me gallium oxide (Ga₂O₃). Ua hōʻike mua nā haʻawina mua i kēia mau mea i ka hiki a me nā pono o ka ʻoki ʻana i ka laser no nā noi semiconductor.

Nīnau: Aia i kēia manawa nā huahana laser slicing ʻoihana makua? I ka pae hea kāu noiʻi?

A: Ua manaʻo nui ʻia nā mea hoʻoheheʻe ʻo SiC laser slicing nui i nā lako koʻikoʻi no ka wā e hiki mai ana o 8-inch SiC wafer production. I kēia manawa, ʻo Iapana wale nō ka mea hiki ke hāʻawi i ia mau ʻōnaehana, a he kumukūʻai lākou a kau ʻia i nā mea hoʻokuʻu aku.

Manaʻo ʻia ke koi ʻana o ka home no nā ʻōnaehana ʻokiʻoki / thinning laser ma kahi o 1,000 mau ʻāpana, e pili ana i nā hoʻolālā hana ʻo SiC a me ka hiki ke ʻike uea. Ua hoʻolilo nui nā ʻoihana kūloko i ka hoʻomohala ʻana, akā ʻaʻole i hiki i nā lako hale kūʻai i loaʻa i ka ʻoihana i hiki i ka hoʻolālā ʻoihana.

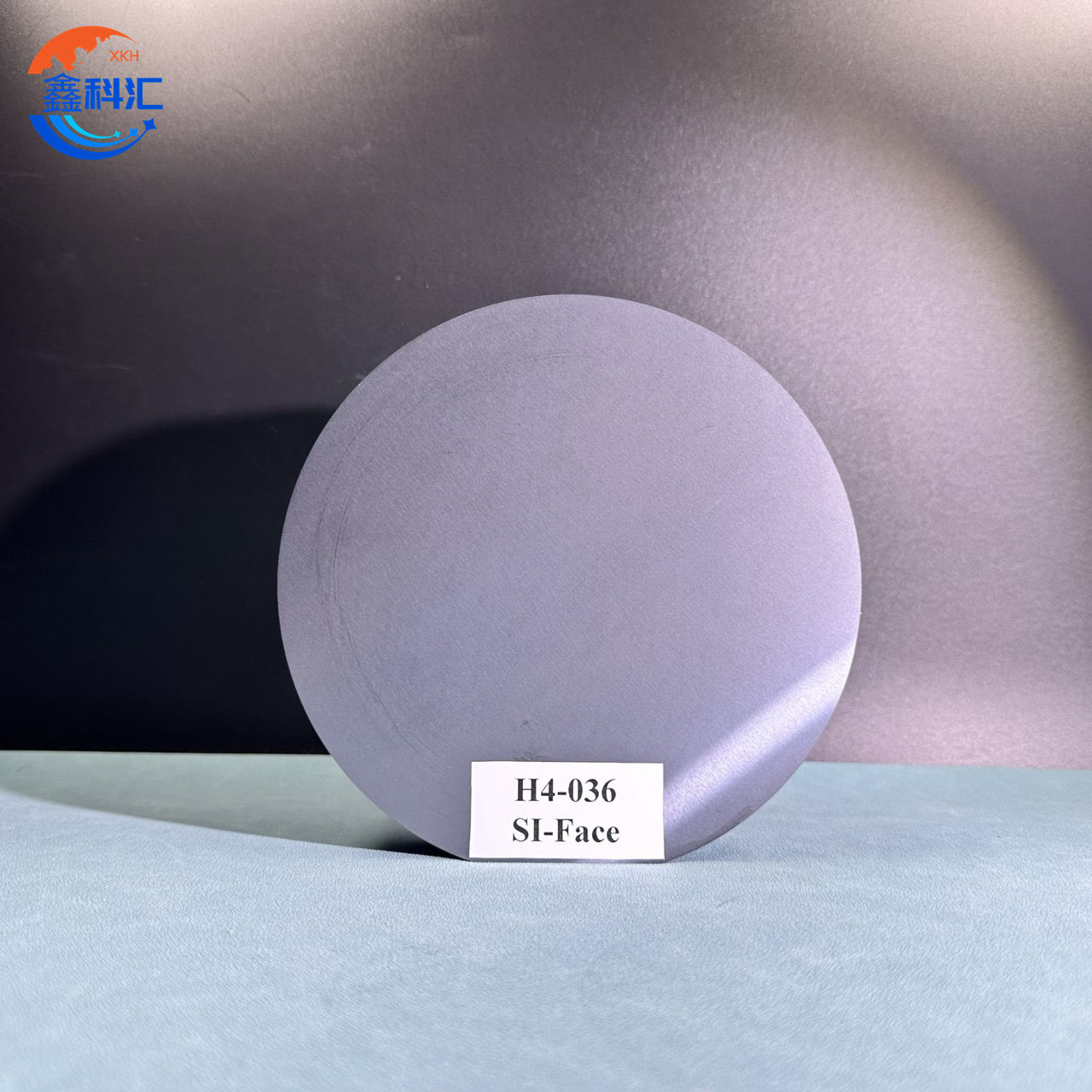

Ke hoʻomohala nei nā pūʻulu noiʻi i ka ʻenehana laser lift-off proprietary mai ka makahiki 2001 a ua hoʻolōʻihi ʻia kēia i ka ʻoki ʻoki a me ka thinning laser nui-diameter. Ua hoʻomohala lākou i kahi ʻōnaehana prototype a me nā kaʻina ʻokiʻoki hiki ke: ʻoki a hoʻoemi 4-6 iniha semi-insulating SiC wafersSlicing 6-8 iniha conductive SiC ingotsNā hōʻailona hana: 6-8 iniha semi-insulating SiC: manawa ʻoki 10-15 minuke/wafer; poho waiwai <30 μm6–8 iniha conductive SiC: slicing manawa 14-20 minuke/wafer; poho waiwai <60 μm

Ua hoʻonui ʻia ka hua wafer ma mua o 50%

Ma hope o ka ʻoki ʻia ʻana, hoʻokō nā wafers i nā kūlana ʻāina no ka geometry ma hope o ka wili ʻana a me ka poli. Hōʻike pū nā haʻawina ʻaʻole pili ka hopena wela i ka laser-induced i ke koʻikoʻi a i ʻole geometry i nā wafers.

Ua hoʻohana ʻia nā mea hana like e hōʻoia i ka hiki ke ʻoki i ke daimana, GaN, a me Ga₂O₃ i nā kristal hoʻokahi.

Ka manawa hoʻouna: Mei-23-2025