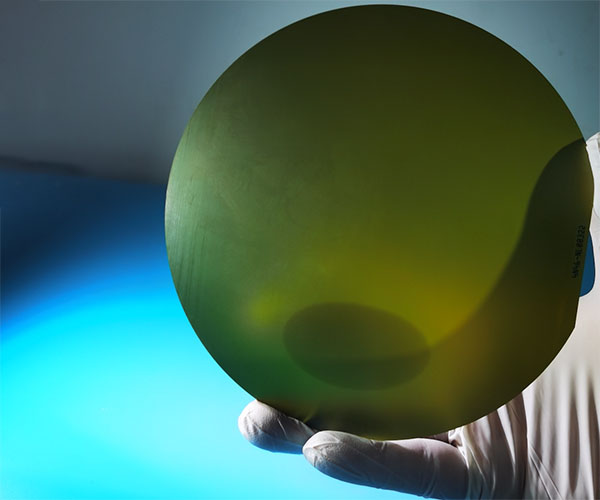

I kēia manawa, hiki i kā mākou hui ke hoʻomau i ka hoʻolako ʻana i nā ʻāpana liʻiliʻi o 8inchN type SiC wafers, inā loaʻa iā ʻoe nā pono hoʻohālike, e ʻoluʻolu e kelepona mai iaʻu. Loaʻa iā mākou kekahi laʻana wafers mākaukau e hoʻouna.

Ma ke kahua o nā mea semiconductor, ua hana ka hui i kahi holomua nui i ka noiʻi a me ka hoʻomohala ʻana i nā kristal SiC nui. Ma ka hoʻohana ʻana i kāna mau kristal hua ponoʻī ma hope o ka hoʻonui ʻia ʻana o ke anawaena, ua ulu maikaʻi ka hui i ka 8-inch N-type SiC crystals, kahi e hoʻoponopono ai i nā pilikia paʻakikī e like me ke kahua wela ʻole, ka haʻihaʻi ʻana a me ka hāʻawi ʻana i ke kinoea i loko o ke kaʻina ulu o 8-inch SIC crystals, a wikiwiki i ka ulu ʻana o nā kristal SIC nui nui a me ka ʻenehana hana autonomous a me ka controllable. Hoʻonui nui i ka hoʻokūkū koʻikoʻi o ka ʻoihana ma ka ʻoihana substrate crystal single SiC. I ka manawa like, hoʻoikaika ikaika ka ʻoihana i ka hōʻiliʻili ʻana o ka ʻenehana a me ke kaʻina o ka nui nui silicon carbide substrate hoʻomākaukau hoʻokolohua laina, hoʻoikaika i ka hoʻololi ʻenehana a me ka hui pū ʻana o ka ʻoihana ma luna a me lalo o nā kula, a hui pū me nā mea kūʻai aku e hoʻomaʻamaʻa mau i ka hana huahana.

| 8 iniha N-type SiC DSP Specs | |||||

| Helu | 'ikamu | Unite | Hana ʻia | Ka noiʻi | Dummy |

| 1. Nā ʻāpana | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | hoʻonohonoho ʻili | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Pilikino uila | |||||

| 2.1 | dopant | -- | n-type Nitrogen | n-type Nitrogen | n-type Nitrogen |

| 2.2 | kūʻē | ohm ·cm | 0.015~0.025 | 0.01~0.03 | NA |

| 3. Pilikino mīkini | |||||

| 3.1 | anawaena | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | mānoanoa | μm | 500±25 | 500±25 | 500±25 |

| 3.3 | ʻO ke kuhi notch | ° | [1- 100]±5 | [1- 100]±5 | [1- 100]±5 |

| 3.4 | Hohonu Notch | mm | 1~1.5 | 1~1.5 | 1~1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Kakaka | μm | -25~25 | -45~45 | -65~65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Kūlana | |||||

| 4.1 | micropipe density | ea/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | mea metala | nā ʻātoma/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ea/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ea/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ea/cm2 | ≤7000 | ≤10000 | NA |

| 5. Ka maikaʻi maikaʻi | |||||

| 5.1 | mua | -- | Si | Si | Si |

| 5.2 | hoʻopau ʻili | -- | Si-maka CMP | Si-maka CMP | Si-maka CMP |

| 5.3 | ʻāpana | ea/wafer | ≤100 (nui≥0.3μm) | NA | NA |

| 5.4 | ʻūlū | ea/wafer | ≤5, Ka huina Length≤200mm | NA | NA |

| 5.5 | Kaulana chips/indents/cracks/stains/contamination | -- | ʻAʻohe | ʻAʻohe | NA |

| 5.6 | Nā wahi polytype | -- | ʻAʻohe | Wahi ≤10% | Wahi ≤30% |

| 5.7 | hoailona mua | -- | ʻAʻohe | ʻAʻohe | ʻAʻohe |

| 6. Ka maikaʻi hope | |||||

| 6.1 | hope hope | -- | C-maka MP | C-maka MP | C-maka MP |

| 6.2 | ʻūlū | mm | NA | NA | NA |

| 6.3 | lihi hemahema hope chips/indents | -- | ʻAʻohe | ʻAʻohe | NA |

| 6.4 | ʻōkalakala kua | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Kaha hope | -- | Notch | Notch | Notch |

| 7. Kaulana | |||||

| 7.1 | lihi | -- | Chamfer | Chamfer | Chamfer |

| 8. Pūʻolo | |||||

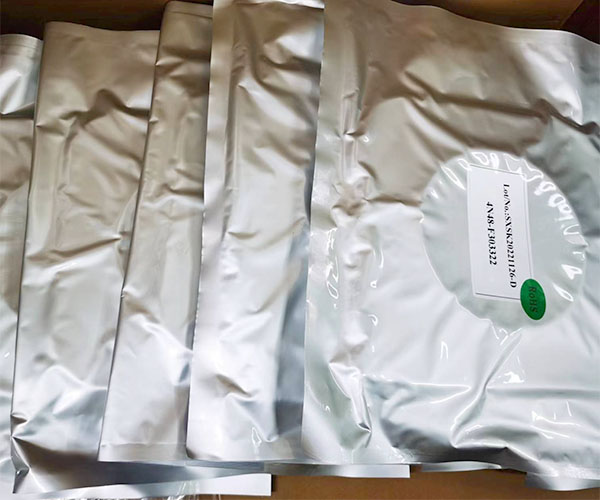

| 8.1 | kāʻei ʻana | -- | Epi-mākaukau me ka vacuum kāʻei ʻana | Epi-mākaukau me ka vacuum kāʻei ʻana | Epi-mākaukau me ka vacuum kāʻei ʻana |

| 8.2 | kāʻei ʻana | -- | Wafer nui hoʻopaʻa cassette | Wafer nui hoʻopaʻa cassette | Wafer nui hoʻopaʻa cassette |

Ka manawa hoʻouna: Apr-18-2023