ʻO ka abstract a SiC wafer

ʻO nā wafers Silicon carbide (SiC).ua lilo i substrate o ke koho no ka mana kiʻekiʻe, kiʻekiʻe-frequency, a me ka wela wela ma waena o ka automotive, ikehu hou, a me ka aerospace. Hoʻopili kā mākou kōpili i nā polytypes nui a me nā papa hana doping—nitrogen-doped 4H (4H-N), high-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), a me ka p-type 4H/6H (4H/6H-P)—i hāʻawi ʻia i ʻekolu mau māka maikaʻi: PRIME (pololei piha, Dpolished-grades a me nā substrates) NUI (nā papa epi maʻamau a me nā ʻaoʻao doping no R&D). He 2″, 4″, 6″, 8″, a me 12″ nā anawaena wafer e kūpono i nā mea hana hoʻoilina a me nā mea hana kiʻekiʻe. Hāʻawi pū mākou i nā boules monocrystalline a me nā kristal hua i hoʻonohonoho pono ʻia e kākoʻo i ka ulu ʻana o ka kristal i loko o ka hale.

ʻO kā mākou mau wafers 4H-N e hōʻike ana i nā densities lawe mai 1 × 10¹⁶ a i 1 × 10¹⁹ cm⁻³ a me nā resistivities o 0.01–10 Ω·cm, e hāʻawi ana i ka mobility electron maikaʻi loa a me nā kahua haʻihaʻi ma luna o 2 MV/cm — kūpono no nā diodes Schottky, MOSFETs. ʻOi aku ka nui o ka pale HPSI i ka 1×10¹² Ω·cm me ka mānoanoa micropipe ma lalo o 0.1 cm⁻², e hōʻoia ana i ka liʻiliʻi liʻiliʻi no nā mea RF a me ka microwave. ʻO Cubic 3C-N, loaʻa i nā ʻano 2″ a me 4″, hiki i ka heteroepitaxy ma ke silika a kākoʻo i nā noi photonic a me MEMS. P-type 4H/6H-P wafers, doped me ka aluminika i 1×10¹⁶–5×10¹⁸ cm⁻³, hoʻomaʻamaʻa i ka hoʻolālā ʻana o nā mea hoʻohui.

ʻO ka wafer SiC, PRIME wafers e hoʻolalelaʻi kemika-mechanical a hiki i ka <0.2 nm RMS kaʻeleʻele o kaʻili, ka nui o ka mānoanoa ma lalo o 3 µm, a me ke kakaka <10 µm. Hoʻonui ka DUMMY substrates i ka hōʻuluʻulu ʻana a me ka hoʻāʻo ʻana, ʻoiai ʻo RESEARCH wafers e hōʻike ana i ka mānoanoa epi-layer o 2-30 µm a me ka doping bespoke. Hoʻopaʻa ʻia nā huahana āpau e ka diffraction X-ray (ka puʻupuʻu haʻalulu <30 arcsec) a me Raman spectroscopy, me nā hoʻāʻo uila—nā ana o ka Hale, C-V profiling, a me ka micropipe scanning—e hōʻoia ana i ka JEDEC a me SEMI.

Hoʻoulu ʻia nā boule a hiki i 150 mm anawaena ma o PVT a me CVD me ka dislocation densities ma lalo o 1×10³ cm⁻² a me nā helu micropipe haʻahaʻa. Hoʻokiʻoki ʻia nā hua kristal i loko o 0.1° o ka axis c e hōʻoia i ka ulu hou ʻana a me nā hua ʻoki kiʻekiʻe.

Ma ka hoʻohui ʻana i nā polytypes he nui, nā ʻano doping, nā māka maikaʻi, nā nui wafer SiC, a me ka boule i loko o ka hale a me ka hana ʻana i nā hua-crystal, ʻo kā mākou SiC substrate platform e hoʻoheheʻe i nā kaulahao lako a hoʻolalelale i ka hoʻomohala ʻana i nā hāmeʻa no nā kaʻa uila, nā mākaʻikaʻi akamai, a me nā noiʻi ʻino.

ʻO ka abstract a SiC wafer

ʻO nā wafers Silicon carbide (SiC).ua lilo i mea koho SiC no ka mana kiʻekiʻe, kiʻekiʻe-frequency, a me ka wela wela ma waena o ka automotive, ikehu hou, a me nā ʻāpana aerospace. Hoʻopili kā mākou kōpili i nā polytypes nui a me nā papa hana doping—nitrogen-doped 4H (4H-N), high-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), a me p-type 4H/6H (4H/6H-P)—i hāʻawi ʻia i ʻekolu mau māka maikaʻi: SiC waferPRIME (nā mea i hoʻomaʻamaʻa piha ʻia, nā papa hana-mea hana), DUMMY (lapped a unpolished no ka hoʻāʻo ʻana), a me RESEARCH (nā papa epi maʻamau a me nā kiʻi doping no R&D). ʻO nā anawaena SiC Wafer he 2″, 4″, 6″, 8″, a me 12″ e kūpono i nā mea hana hoʻoilina a me nā mea hana kiʻekiʻe. Hāʻawi pū mākou i nā boules monocrystalline a me nā kristal hua i hoʻonohonoho pono ʻia e kākoʻo i ka ulu ʻana o ka kristal i loko o ka hale.

ʻO kā mākou 4H-N SiC wafers e hōʻike ana i nā density lawe mai 1 × 10¹⁶ a i 1 × 10¹⁹ cm⁻³ a me nā resistivities o 0.01–10 Ω·cm, e hāʻawi ana i ka mobility electron maikaʻi loa a me nā kahua haʻihaʻi ma luna o 2 MV/cm — kūpono no nā diodes Schottky, a me, MOSFETky. ʻOi aku ka nui o ka pale HPSI i ka 1×10¹² Ω·cm me ka mānoanoa micropipe ma lalo o 0.1 cm⁻², e hōʻoia ana i ka liʻiliʻi liʻiliʻi no nā mea RF a me ka microwave. ʻO Cubic 3C-N, loaʻa i nā ʻano 2″ a me 4″, hiki i ka heteroepitaxy ma ke silika a kākoʻo i nā noi photonic a me MEMS. ʻO SiC wafer P-type 4H/6H-P wafers, i hoʻopaʻa ʻia me ka alumini i 1×10¹⁶–5×10¹⁸ cm⁻³, hoʻomaʻamaʻa i nā hale hana hoʻohui.

ʻO SiC wafer PRIME wafers e hoʻolale ʻia i kemika-mechanical polishing a hiki i ka <0.2 nm RMS ʻeleʻele o ka ʻili, ka nui o ka mānoanoa ma lalo o 3 µm, a me ke kakaka <10 µm. Hoʻonui ka DUMMY substrates i ka hōʻuluʻulu ʻana a me ka hoʻāʻo ʻana, ʻoiai ʻo RESEARCH wafers e hōʻike ana i ka mānoanoa epi-layer o 2-30 µm a me ka doping bespoke. Hoʻopaʻa ʻia nā huahana āpau e ka diffraction X-ray (ka puʻupuʻu haʻalulu <30 arcsec) a me Raman spectroscopy, me nā hoʻāʻo uila—nā ana o ka Hale, C-V profiling, a me ka micropipe scanning—e hōʻoia ana i ka JEDEC a me SEMI.

Hoʻoulu ʻia nā boule a hiki i 150 mm anawaena ma o PVT a me CVD me ka dislocation densities ma lalo o 1×10³ cm⁻² a me nā helu micropipe haʻahaʻa. Hoʻokiʻoki ʻia nā hua kristal i loko o 0.1° o ka axis c e hōʻoia i ka ulu hou ʻana a me nā hua ʻoki kiʻekiʻe.

Ma ka hoʻohui ʻana i nā polytypes he nui, nā ʻano doping, nā māka maikaʻi, nā nui wafer SiC, a me ka boule i loko o ka hale a me ka hana ʻana i nā hua-crystal, ʻo kā mākou SiC substrate platform e hoʻoheheʻe i nā kaulahao lako a hoʻolalelale i ka hoʻomohala ʻana i nā hāmeʻa no nā kaʻa uila, nā mākaʻikaʻi akamai, a me nā noiʻi ʻino.

6 ʻīniha 4H-N ʻano SiC wafer pepa ʻikepili

| 6 ʻīniha SiC wafers pepa ʻikepili | ||||

| ʻĀpana | Palena Haʻahaʻa | Z Papa | P Papa | Papa D |

| Anawaena | 149.5–150.0 mm | 149.5–150.0 mm | 149.5–150.0 mm | |

| mānoanoa | 4H‑N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| mānoanoa | 4H‑SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Kūlana Wafer | Koi aku: 4.0° i ka <11-20> ± 0.5° (4H-N); Ma ke axis: <0001> ± 0.5° (4H-SI) | Koi aku: 4.0° i ka <11-20> ± 0.5° (4H-N); Ma ke axis: <0001> ± 0.5° (4H-SI) | Koi aku: 4.0° i ka <11-20> ± 0.5° (4H-N); Ma ke axis: <0001> ± 0.5° (4H-SI) | |

| Micropipe Density | 4H‑N | ≤ 0.2 knm⁻² | ≤ 2 knm⁻² | ≤ 15 knm⁻² |

| Micropipe Density | 4H‑SI | ≤ 1 knm⁻² | ≤ 5 knm⁻² | ≤ 15 knm⁻² |

| Kū'ē | 4H‑N | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| Kū'ē | 4H‑SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1×10⁵ Ω·cm | |

| Kūlana Pāha mua | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Ka lōʻihi pālahalaha | 4H‑N | 47.5 mm ± 2.0 mm | ||

| Ka lōʻihi pālahalaha | 4H‑SI | Notch | ||

| Hoʻokuʻu Edge | 3 mm | |||

| Warp/LTV/TTV/Bow | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| ʻoʻoleʻa | Pōlani | Ra ≤ 1 nm | ||

| ʻoʻoleʻa | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Nā māwae Edge | ʻAʻohe | ʻO ka lōʻihi hui ≤ 20 mm, hoʻokahi ≤ 2 mm | ||

| Papa Hex | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 0.1% | ʻĀpana hui ≤ 1% | |

| Nā ʻāpana Polytype | ʻAʻohe | ʻĀpana hui ≤ 3% | ʻĀpana hui ≤ 3% | |

| Hoʻokomo kalapona | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 3% | ||

| Nā ʻili ʻili | ʻAʻohe | Huina lōʻihi ≤ 1 × wafer anawaena | ||

| ʻOpeʻa Kiki | ʻAʻole ʻae ʻia ≥ 0.2 mm laula a me ka hohonu | A hiki i 7 chips, ≤ 1 mm kēlā me kēia | ||

| TSD (Hoʻokaʻawale ʻia ʻo Threading Screw Dislocation) | ≤ 500 knm⁻² | N/A | ||

| BPD (Hoʻokaʻawale ʻia ʻo Base Plane) | ≤ 1000 knm⁻² | N/A | ||

| Hoʻohaumia ʻili | ʻAʻohe | |||

| Hoʻopili ʻana | ʻO ka cassette multi-wafer a i ʻole ka pahu wafer hoʻokahi | ʻO ka cassette multi-wafer a i ʻole ka pahu wafer hoʻokahi | ʻO ka cassette multi-wafer a i ʻole ka pahu wafer hoʻokahi | |

4 ʻīniha 4H-N ʻano SiC wafer pepa ʻikepili

| 4 ʻīniha SiC wafer pepa ʻikepili | |||

| ʻĀpana | ʻO Zero MPD Production | Papa Hana Maʻamau (P Grade) | Papa Dummy (Papa D) |

| Anawaena | 99.5 mm–100.0 mm | ||

| Mānoanoa (4H-N) | 350 µm±15 µm | 350 µm±25 µm | |

| Mānoanoa (4H-Si) | 500 µm±15 µm | 500 µm±25 µm | |

| Kūlana Wafer | Koi aku: 4.0° i ka <1120> ± 0.5° no 4H-N; Ma ke axis: <0001> ± 0.5° no 4H-Si | ||

| ʻOiʻa Micropipe (4H-N) | ≤0.2 knm⁻² | ≤2 knm⁻² | ≤15 knm⁻² |

| ʻOiʻa Micropipe (4H-Si) | ≤1 knm⁻² | ≤5 knm⁻² | ≤15 knm⁻² |

| Kū'ē (4H-N) | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | |

| Kū'ē (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Kūlana Pāha mua | [10-10] ±5.0° | ||

| Ka lōʻihi pālahalaha | 32.5 mm ±2.0 mm | ||

| Ka lōʻihi pālahalaha lua | 18.0 mm ±2.0 mm | ||

| Kūlana Pāpā lua | Ke alo i luna: 90° CW mai ka palahalaha nui ± 5.0° | ||

| Hoʻokuʻu Edge | 3 mm | ||

| LTV/TTV/Ka Kakaka | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| ʻoʻoleʻa | Polani Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Nā Māwae ʻO Edge Ma ka Māmā ʻO ke Kiʻekiʻe | ʻAʻohe | ʻAʻohe | ʻO ka lōʻihi huila ≤10 mm; hoʻokahi lōʻihi ≤2 mm |

| Nā Papa Hex Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤0.05% | ʻĀpana hui ≤0.05% | ʻĀpana hui ≤0.1% |

| Nā ʻāpana Polytype Ma ka Māmā Kiʻekiʻe | ʻAʻohe | ʻĀpana hui ≤3% | |

| Hoʻokomo ʻia ʻo Carbon Visual | ʻĀpana hui ≤0.05% | ʻĀpana hui ≤3% | |

| ʻO ka ʻili o ka ʻili silikoni e ka māmā ikaika loa | ʻAʻohe | ʻO ka lōʻihi huila ≤1 anawaena wafer | |

| Nā Kiʻi Kiʻi Ma ka Māmā Kiʻekiʻe | ʻAʻole ʻae ʻia ≥0.2 mm laula a me ka hohonu | 5 ʻae ʻia, ≤1 mm kēlā me kēia | |

| ʻO ka hoʻohaumia ʻana i ka ʻili o ka Silicon e ka māmā ikaika kiʻekiʻe | ʻAʻohe | ||

| ʻO ka wehe ʻana i ka wili wili | ≤500 knm⁻² | N/A | |

| Hoʻopili ʻana | ʻO ka cassette multi-wafer a i ʻole ka pahu wafer hoʻokahi | ʻO ka cassette multi-wafer a i ʻole ka pahu wafer hoʻokahi | ʻO ka cassette multi-wafer a i ʻole ka pahu wafer hoʻokahi |

4 ʻīniha HPSI ʻano SiC wafer pepa ʻikepili

| 4 ʻīniha HPSI ʻano SiC wafer pepa ʻikepili | |||

| ʻĀpana | ʻAʻohe papa hana MPD (Z Grade) | Papa Hana Maʻamau (P Grade) | Papa Dummy (Papa D) |

| Anawaena | 99.5–100.0 mm | ||

| Mānoanoa (4H-Si) | 500 µm ±20 µm | 500 µm ±25 µm | |

| Kūlana Wafer | Paʻa axis: 4.0° i ka <11-20> ± 0.5° no 4H-N; Ma ke axis: <0001> ± 0.5° no 4H-Si | ||

| ʻOiʻa Micropipe (4H-Si) | ≤1 knm⁻² | ≤5 knm⁻² | ≤15 knm⁻² |

| Kū'ē (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Kūlana Pāha mua | (10-10) ±5.0° | ||

| Ka lōʻihi pālahalaha | 32.5 mm ±2.0 mm | ||

| Ka lōʻihi pālahalaha lua | 18.0 mm ±2.0 mm | ||

| Kūlana Pāpā lua | Ke alo i luna: 90° CW mai ka palahalaha nui ± 5.0° | ||

| Hoʻokuʻu Edge | 3 mm | ||

| LTV/TTV/Ka Kakaka | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| 'O'ole'e (C alo) | Pōlani | Ra ≤1 nm | |

| Roughness (Si alo) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Nā Māwae ʻO Edge Ma ka Māmā ʻO ke Kiʻekiʻe | ʻAʻohe | ʻO ka lōʻihi huila ≤10 mm; hoʻokahi lōʻihi ≤2 mm | |

| Nā Papa Hex Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤0.05% | ʻĀpana hui ≤0.05% | ʻĀpana hui ≤0.1% |

| Nā ʻāpana Polytype Ma ka Māmā Kiʻekiʻe | ʻAʻohe | ʻĀpana hui ≤3% | |

| Hoʻokomo ʻia ʻo Carbon Visual | ʻĀpana hui ≤0.05% | ʻĀpana hui ≤3% | |

| ʻO ka ʻili o ka ʻili silikoni e ka māmā ikaika loa | ʻAʻohe | ʻO ka lōʻihi huila ≤1 anawaena wafer | |

| Nā Kiʻi Kiʻi Ma ka Māmā Kiʻekiʻe | ʻAʻole ʻae ʻia ≥0.2 mm laula a me ka hohonu | 5 ʻae ʻia, ≤1 mm kēlā me kēia | |

| ʻO ka hoʻohaumia ʻana i ka ʻili o ka Silicon e ka māmā ikaika kiʻekiʻe | ʻAʻohe | ʻAʻohe | |

| Hoʻokaʻawale ʻia ka Uila Uila | ≤500 knm⁻² | N/A | |

| Hoʻopili ʻana | ʻO ka cassette multi-wafer a i ʻole ka pahu wafer hoʻokahi | ||

Ke noi a SiC wafer

-

Nā Module Mana Wafer SiC no nā mea hoʻohuli EV

ʻO nā MOSFET a me nā diodes e pili ana i ka wafer SiC i kūkulu ʻia ma luna o nā substrates wafer SiC kiʻekiʻe e hāʻawi i nā poho hoʻololi haʻahaʻa haʻahaʻa. Ma ka hoʻohana ʻana i ka ʻenehana wafer SiC, e hana ana kēia mau mana mana i nā volt kiʻekiʻe a me nā mahana, e hiki ai i nā mea hoʻohuli traction ʻoi aku ka maikaʻi. ʻO ka hoʻohui ʻana i ka wafer SiC make i nā pae mana e hōʻemi i nā koi hoʻoluʻu a me ka wāwae, e hōʻike ana i ka piha piha o ka SiC wafer innovation. -

Nā mea RF a me 5G kiʻekiʻe ma SiC Wafer

ʻO nā mea hoʻonui a me nā mea hoʻololi RF i hana ʻia ma nā ʻanuʻu semi-insulating SiC wafer e hōʻike ana i ka conductivity thermal kiʻekiʻe a me ka puʻuwai haki. Hoʻemi ka SiC wafer substrate i nā poho dielectric ma nā alapine GHz, ʻoiai ʻo ka ikaika waiwai o SiC wafer e hiki ai ke hana paʻa ma lalo o ka mana kiʻekiʻe, nā kūlana wela kiʻekiʻe - e hoʻolilo iā SiC wafer i mea koho no nā kahua kahua 5G a me nā ʻōnaehana radar. -

Optoelectronic & LED Substrates mai SiC Wafer

Pōmaikaʻi nā kukui ʻulaʻula a me nā UV i ulu ʻia ma nā substrate wafer SiC mai ka hoʻohālikelike ʻana i ka lattice maikaʻi loa a me ka hoʻopau wela. ʻO ka hoʻohana ʻana i ka wafer C-face SiC e hōʻoiaʻiʻo ai i nā papa epitaxial like ʻole, ʻoiai ʻo ka paʻakikī paʻa o ka wafer SiC e hiki ai ke hoʻokaʻawale i ka wafer maikaʻi a me ka hoʻopili pono ʻana o nā hāmeʻa. Hoʻolilo kēia iā SiC wafer i ke kahua hele no ka mana kiʻekiʻe, nā noi LED lōʻihi.

Nīnau a SiC wafer

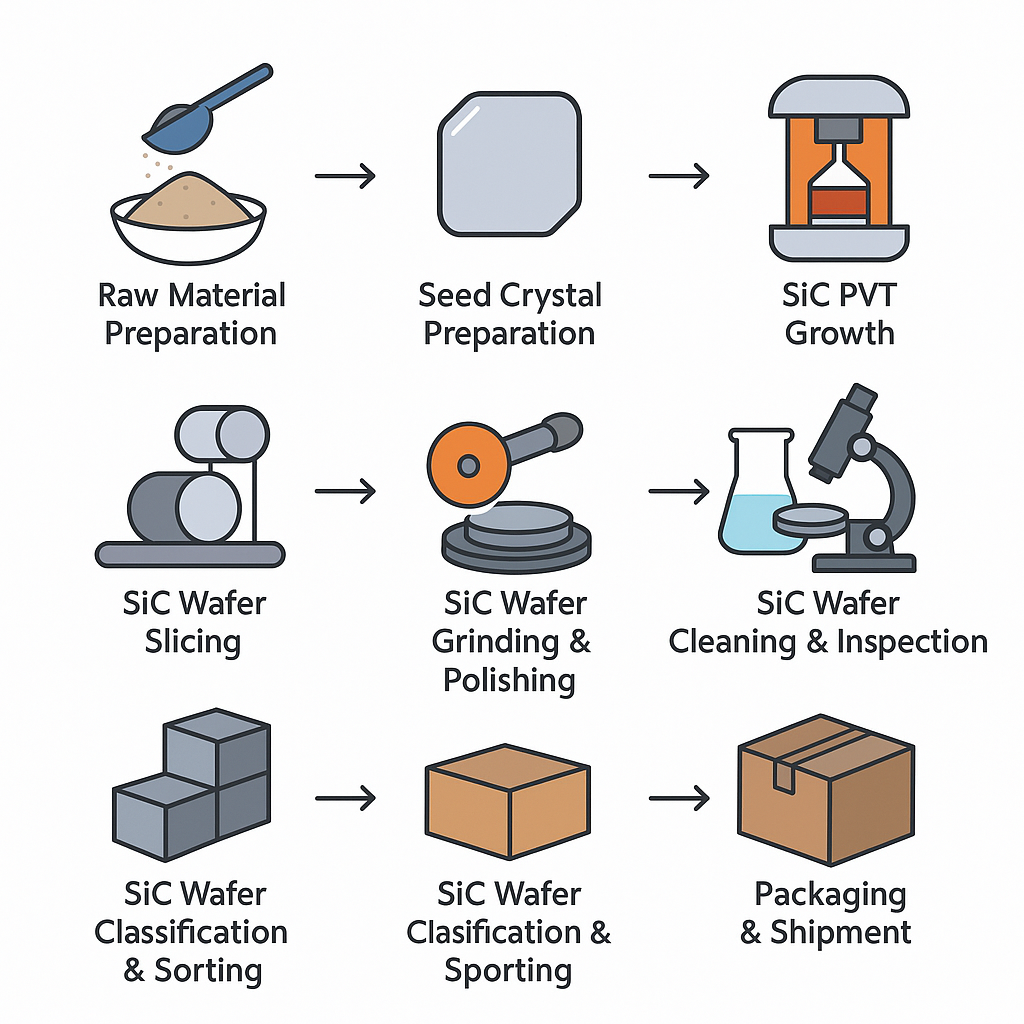

1. Nīnau: Pehea e hana ʻia ai nā wafers SiC?

A:

Hana ʻia nā wafers SiCNā ʻanuʻu kikoʻī

-

SiC wafersHoʻomākaukau Mea Maka

- E hoʻohana i ka pauka SiC ≥5N-grade (nā haumia ≤1 ppm).

- E kānana a e hoʻomoʻa mua e wehe i ke koena carbon a i ʻole nā pūhui nitrogen.

-

SiCHoʻomākaukau Huaʻala Crystal

-

E lawe i kahi ʻāpana 4H-SiC hoʻokahi aniani, ʻokiʻoki ma ka ʻaoʻao 〈0001〉 i ~10 × 10 mm².

-

Pololei pololei iā Ra ≤0.1 nm a e kaha i ka ʻano aniani.

-

-

SiCKa Ulu ʻana o PVT (Ka lawe ʻana i ka mahu kino)

-

E hoʻouka i ka graphite crucible: lalo me ka pauka SiC, luna me ke aniani hua.

-

E hoʻoneʻe i 10⁻³–10⁻⁵ Torr a i ʻole backfill me ka helium maʻemaʻe kiʻekiʻe ma 1 atm.

-

ʻO ka ʻāpana kumu wela i 2100–2300 ℃, mālama i ka ʻāpana hua 100–150 ℃ maʻalili.

-

E hoʻomalu i ka ulu ulu ma 1-5 mm / h e kaulike i ka maikaʻi a me ka hana.

-

-

SiCHoʻohuihui Ingot

-

Hoʻopili i ka ingot SiC i ulu ʻia ma 1600–1800 ℃ no 4-8 mau hola.

-

Ke kumu: hoʻokuʻu i nā kaumaha wela a hoʻemi i ka nui o ka dislocation.

-

-

SiCWafer Slicing

-

E ho ohana i ka uwea daimana e oki i ka ingot i loko o ka manoanoa 0.5-1 mm.

-

E hōʻemi i ka haʻalulu a me ka ikaika ʻaoʻao e pale i nā micro-cracks.

-

-

SiCWaferʻO ka wili a me ka ʻoliʻoli

-

Ka wili ʻanano ka wehe ʻana i ka pōʻino o ka ʻili ʻana (ka ʻeleʻele ~ 10-30 µm).

-

ʻO ka wili maikaʻie hoʻokō i ka palahalaha ≤5 µm.

-

Kemikini-Mechanical Polishing (CMP)e hiki i ke aniani-like pau (Ra ≤0.2 nm).

-

-

SiCWaferHoomaemae & Nana

-

Hoʻomaʻemaʻe kani ultrasonici ka hoʻonā Piranha (H₂SO₄:H₂O₂), DI wai, a laila IPA.

-

XRD/Raman spectroscopye hōʻoia i ka polytype (4H, 6H, 3C).

-

Interferometrye ana i ka palahalaha (<5 µm) a me ke kaua (<20 µm).

-

ʻEhā kuhi ʻimie ho'āʻo i ka resistivity (e laʻa me HPSI ≥10⁹ Ω·cm).

-

Nānā hemahemama lalo o ka microscope māmā polarized a me ka mea hōʻike ʻōpala.

-

-

SiCWaferHoʻokaʻawale a hoʻokaʻawale

-

Hoʻokaʻawale i nā wafers ma ke ʻano polytype a me ke ʻano uila:

-

4H-SiC N-ʻano (4H-N): ka hoʻopaʻa ʻana o ka mea lawe 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC High Purity Semi-Insulating (4H-HPSI): resistivity ≥10⁹ Ω·cm

-

6H-SiC N-ʻano (6H-N)

-

Nā mea ʻē aʻe: 3C-SiC, P-type, etc.

-

-

-

SiCWaferPuke & Hoouna

2. Nīnau: He aha nā pōmaikaʻi nui o nā wafers SiC ma mua o nā wafers silicon?

A: Hoʻohālikelike ʻia me nā wafer silika, hiki i nā wafers SiC:

-

ʻOi aku ka nui o ka hana uila(>1,200 V) me ka haʻahaʻa ma ke kū'ē.

-

Paʻa wela kiʻekiʻe(>300 °C) a hoʻomaikaʻi i ka hoʻokele wela.

-

ʻOi aku ka wikiwiki o ka hoʻololi ʻaname nā poho hoʻololi haʻahaʻa, e hōʻemi ana i ka hoʻoluʻu pae ʻōnaehana a me ka nui o nā mea hoʻololi mana.

4. Nīnau: He aha nā hemahema maʻamau e pili ana i ka SiC wafer yield a me ka hana?

A: ʻO nā hemahema nui o nā wafers SiC he micropipes, basal plane dislocations (BPDs), a me nā ʻōpala ʻili. Hiki i nā micropipes ke hoʻopōʻino i nā mea hana; Hoʻonui ka BPD i ke kū'ē i ka manawa; a ʻo nā ʻōpala ili ke alakaʻi i ka haʻihaʻi wafer a i ʻole ka ulu ʻana o ka epitaxial maikaʻi ʻole. No laila, pono ka nānā pono ʻana a me ka hoʻēmi ʻana i nā hemahema e hoʻonui ai i ka hua wafer SiC.

Ka manawa hoʻouna: Iune-30-2025