Mai ke kumu hana o nā LED, ʻike ʻia ʻo ka epitaxial wafer material ka mea nui o kahi LED. ʻO ka ʻoiaʻiʻo, ʻo nā ʻāpana optoelectronic koʻikoʻi e like me ka lōʻihi o ka nalu, ka ʻōlinolino, a me ka volter mua i hoʻoholo nui ʻia e ka mea epitaxial. He mea koʻikoʻi ka ʻenehana wafer epitaxial i ke kaʻina hana, me ka Metal-Organic Chemical Vapor Deposition (MOCVD) ʻo ia ke ʻano kumu mua no ka ulu ʻana i nā ʻāpana kalakala lahilahi o III-V, II-VI pūhui, a me kā lākou mau ala. Ma lalo iho nei kekahi mau ʻano e hiki mai ana i ka ʻenehana wafer epitaxial LED.

1. Hoʻomaikaʻi ʻana i ke kaʻina hana ulu ʻelua

I kēia manawa, hoʻohana ka hana ʻoihana i kahi kaʻina hana ulu ʻelua, akā palena ʻia ka helu o nā substrates i hiki ke hoʻouka ʻia i ka manawa hoʻokahi. ʻOiai ua oʻo nā ʻōnaehana 6-wafer, ke kūkulu ʻia nei nā mīkini e lawelawe ana ma kahi o 20 wafers. ʻO ka hoʻonui ʻana i ka nui o nā wafers e alakaʻi pinepine ai i ka lawa ʻole o ka like ʻole i nā papa epitaxial. E kālele ana nā hanana e hiki mai ana ma nā ʻaoʻao ʻelua:

- Ke hoʻomohala nei i nā ʻenehana e ʻae ai i ka hoʻouka ʻana i nā substrate hou aʻe i loko o kahi keʻena pane hoʻokahi, e kūpono ana iā lākou no ka hana nui a me ka hōʻemi ʻana i ke kumukūʻai.

- ʻO ka hoʻonui ʻana i nā lako wafer hoʻokahi.

2. Hydride Vapor Phase Epitaxy (HVPE) Technology

Hiki i kēia ʻenehana ke ulu wikiwiki i nā kiʻiʻoniʻoni mānoanoa me ka haʻahaʻa dislocation haʻahaʻa, hiki ke lilo i substrate no ka ulu ʻana o ka homepitaxial me nā ʻano hana ʻē aʻe. Eia hou, hiki i nā kiʻiʻoniʻoni GaN i hoʻokaʻawale ʻia mai ka substrate ke lilo i mau mea ʻē aʻe i ka nui o ka GaN pākahi-crystal chips. Eia nō naʻe, loaʻa i ka HVPE nā drawbacks, e like me ka paʻakikī i ka mālama ʻana i ka mānoanoa pololei a me nā kinoea hopena corrosive e keʻakeʻa nei i ka hoʻomaikaʻi hou ʻana i ka hoʻomaʻemaʻe waiwai GaN.

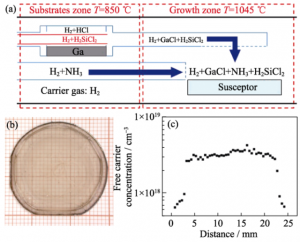

Si-doped HVPE-GaN

(a) Hoʻonohonoho o ka reactor HVPE-GaN Si-doped; (b) Kiʻi o 800 μm- mānoanoa Si-doped HVPE-GaN;

(c) Ka puunaue ana o ka lawe manuahi ma ke anawaena o Si-doped HVPE-GaN

3. Epitaxial Growth koho a i ole Lateral Epitaxial Growth Technology

Hiki i kēia ʻenehana ke hōʻemi hou i ka dislocation density a hoʻomaikaʻi i ka maikaʻi kristal o nā papa epitaxial GaN. Aia ke kaʻina hana:

- Ka waiho ʻana i kahi papa GaN ma kahi substrate kūpono (sapphire a i ʻole SiC).

- E waiho ana i ka polycrystalline SiO₂ mask ma luna.

- Ke hoʻohana nei i ka photolithography a me ka etching e hana i nā puka makani GaN a me nā ʻāpana mask SiO₂.I ka wā o ka ulu ʻana ma hope, ulu mua ʻo GaN i ke kū pololei ma nā puka makani a ma hope ma luna o nā ʻāpana SiO₂.

XKH's GaN-on-Sapphire wafer

4. ʻenehana Pendeo-Epitaxy

Hoʻemi nui kēia ʻano hana i nā hemahema lattice i hoʻokumu ʻia e ka lattice a me ka thermal mismatch ma waena o ka substrate a me ka papa epitaxial, e hoʻonui hou ana i ka maikaʻi kristal GaN. Aia nā ʻanuʻu:

- Ke ulu nei i kahi papa epitaxial GaN ma kahi substrate kūpono (6H-SiC a i ʻole Si) me ka hoʻohana ʻana i kahi kaʻina hana ʻelua.

- Ke hana ʻana i ke kālai koho ʻana o ka papa epitaxial i lalo i ka substrate, e hana ana i nā kia ʻokoʻa (GaN/buffer/substrate) a me nā hale ʻauwaha.

- Ke ulu nei i nā papa GaN hou, e hohola ana ma ka ʻaoʻao mai nā ʻaoʻao ʻaoʻao o nā kia GaN kumu, i hoʻokuʻu ʻia ma luna o nā ʻauwaha.No ka mea ʻaʻole hoʻohana ʻia kahi mask, pale kēia i ka pilina ma waena o GaN a me nā mea mask.

XKH's GaN-on-Silicon wafer

5. Hoʻomohala ʻana i nā mea epitaxial LED pōkole pōkole UV LED

Hoʻokumu kēia i kahi kumu paʻa no nā LED keʻokeʻo phosphor-excited UV. Hiki ke hoʻohauʻoli ʻia ka nui o nā phosphors kiʻekiʻe e ke kukui UV, e hāʻawi ana i ka ʻoi aku ka maikaʻi o ka luminous ma mua o ka YAG:Ce system o kēia manawa, a laila e holomua ana i ka hana LED keʻokeʻo.

6. ʻenehana Chip Multi-Quantum Well (MQW).

I loko o nā hale MQW, hoʻopau ʻia nā mea haumia like ʻole i ka wā e ulu ana ka papa kukui e hana i nā pūnāwai quantum like ʻole. ʻO ka hui hou ʻana o nā kiʻi i hoʻokuʻu ʻia mai kēia mau pūnāwai e hoʻopuka pololei i ke kukui keʻokeʻo. Hoʻomaikaʻi kēia ʻano hana i ka pono o ka luminous, hōʻemi i nā kumukūʻai, a maʻalahi hoʻi i ka hoʻopili ʻana a me ka hoʻokele kaapuni, ʻoiai ke hōʻike nei ia i nā pilikia ʻenehana nui aʻe.

7. Hoʻomohala ʻana i ka ʻenehana "Photon Recycling".

I Ianuali 1999, ua kūkulu ʻo Sumitomo o Iapana i kahi LED keʻokeʻo me ka hoʻohana ʻana i nā mea ZnSe. Hoʻopili ka ʻenehana i ka hoʻoulu ʻana i kahi kiʻiʻoniʻoni ʻoniʻoni CdZnSe ma kahi substrate kristal hoʻokahi ZnSe. Ke hoʻohana ʻia ka uila, hoʻopuka ke kiʻiʻoniʻoni i ke kukui polū, e hui pū ana me ka substrate ZnSe e hana i ke kukui melemele hoʻohui, e hopena i ke kukui keʻokeʻo. Pēlā nō, hoʻopaʻa ʻia ʻo Boston University's Photonics Research Center i kahi hui semiconductor AlInGaP ma luna o kahi GaN-LED polū e hana i ke kukui keʻokeʻo.

8. LED Epitaxial Wafer Kaʻina Kaʻina

① Epitaxial Wafer Fabrication:

Lapaʻa → Hoʻolālā hoʻolālā → Ka ulu ʻana o ka papa pale → Ka ulu ʻana o ka papa GaN ʻano N → ka ulu ʻana o ka papa hoʻomāmā māmā MQW → Ka ulu ʻana o ka papa P-type GaN → Annealing → Hoʻāʻo (photoluminescence, X-ray) → Epitaxial wafer

② ʻO ka hana chip:

Epitaxial wafer → Hoʻolālā mask a me ka hana ʻana → Photolithography → Ion etching → N-type electrode (deposition, annealing, etching) → P-type electrode (deposition, annealing, etching) → Dicing → Chip inspection and grading.

ʻO ka wafer GaN-on-SiC a ZMSH

Ka manawa hoʻouna: Iulai-25-2025