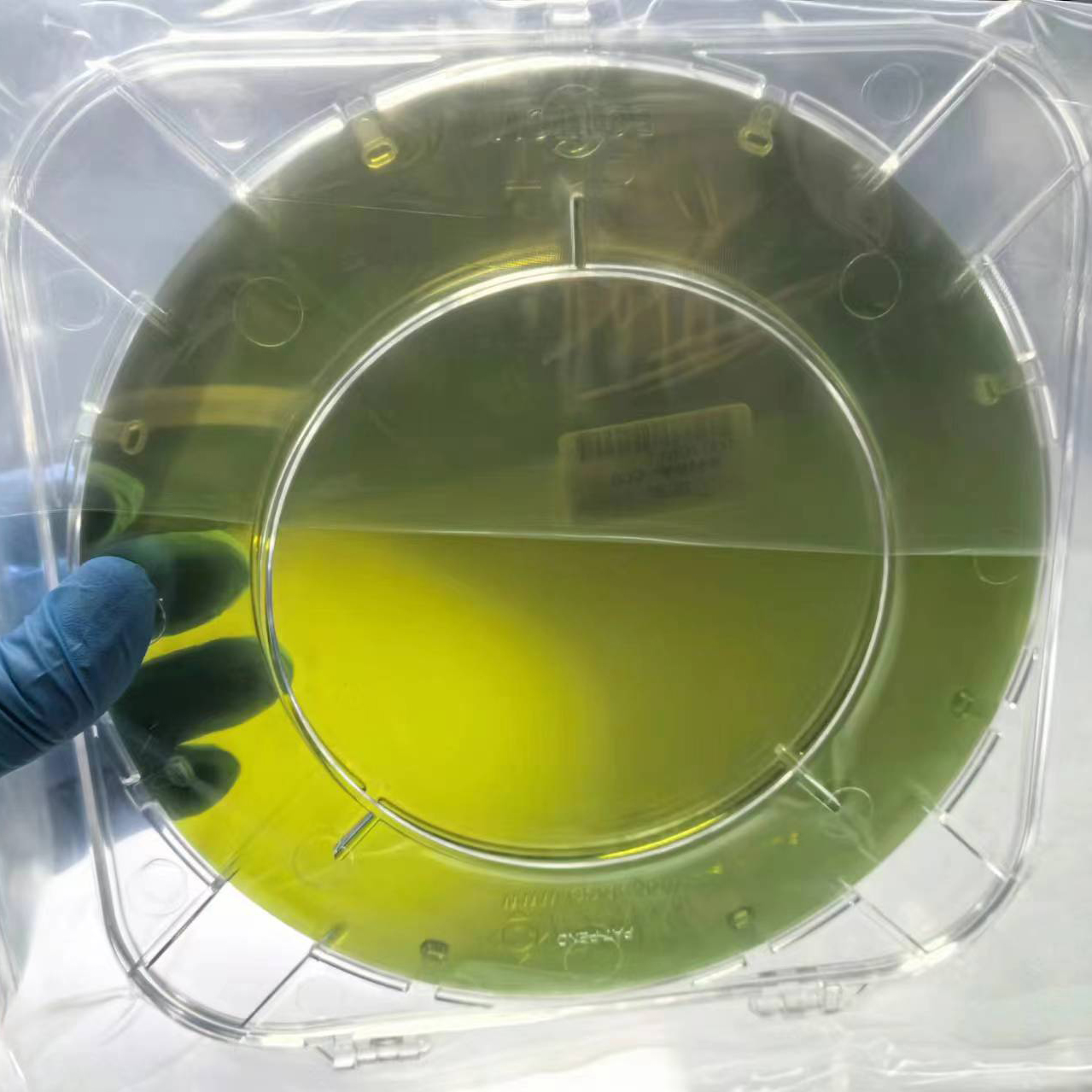

4inihi 6inihi 8 ʻīniha SiC Crystal Growth Furnace for CVD Process

Kumu Hana

ʻO ke kumu kumu o kā mākou ʻōnaehana CVD e pili ana i ka hoʻoheheʻe wela o ka silicon-containing (eg, SiH4) a me ka carbon-containing (eg, C3H8) precursor gases ma nā wela kiʻekiʻe (maʻamau 1500-2000 ° C), e waiho ana i nā kristal hoʻokahi SiC ma nā substrates ma o nā hopena kemika. He kūpono loa kēia ʻenehana no ka hana ʻana i ka maʻemaʻe kiʻekiʻe (> 99.9995%) 4H/6H-SiC hoʻokahi kristal me ka haʻahaʻa haʻahaʻa haʻahaʻa (<1000/cm²), e hoʻokō ana i nā koi koi pono no ka uila uila a me nā polokalamu RF. Ma o ka mana pololei o ka haku kinoea, kahe kahe a me ka mahana gradient, hiki i ka ʻōnaehana ke hoʻoponopono pololei i ke ʻano conductivity crystal (N/P type) a me ka resistivity.

Nā ʻano ʻōnaehana a me nā ʻāpana ʻenehana

| ʻAno Pūnaehana | Kaulana Mahana | Nā mea nui | Nā noi |

| CVD Kūlana Kiʻekiʻe | 1500-2300°C | ʻO ka hoʻomehana ʻana o ka graphite, ± 5 ° C ka like ʻana o ka mahana | ʻO ka ulu ʻana o ka kristal SiC nui |

| CVD-Filament wela | 800-1400°C | ʻO ka hoʻomehana filament Tungsten, 10-50μm / h deposition rate | Epitaxy mānoanoa SiC |

| VPE CVD | 1200-1800°C | ʻO ka mana wela o nā ʻāpana he nui,> 80% hoʻohana kinoea | Hana nui ʻia epi-wafer |

| PECVD | 400-800°C | Hoʻonui ʻia ka plasma, 1-10μm/h deposition rate | Nā kiʻiʻoniʻoni lahilahi SiC haʻahaʻa |

Nā ʻano ʻenehana nui

1. Pūnaehana Kūlana Kūlana Kiʻekiʻe

Hōʻike ka umu ahi i kahi ʻōnaehana hoʻomehana resistive multi-zone e hiki ke mālama i nā mahana a hiki i 2300 ° C me ± 1 ° C like ʻole ma waena o ke keʻena ulu holoʻokoʻa. Hoʻokō ʻia kēia hoʻokele thermal precision ma o:

12 mau wahi hoʻomehana kūʻokoʻa.

ʻO ka nānā ʻana i ka thermocouple ʻē aʻe (Type C W-Re).

ʻO nā algorithms hoʻoponopono hoʻoponopono wela i ka manawa maoli.

ʻO nā paia keʻena hoʻoluʻu wai no ka hoʻomalu gradient thermal.

2. Hoʻouna kinoea a hui ʻenehana

ʻO kā mākou ʻōnaehana hoʻoili kinoea waiwai e hōʻoia i ka hui ʻana o ka precursor maikaʻi loa a me ka hāʻawi like ʻana:

Nā mea hoʻoponopono kahe nui me ± 0.05sccm pololei.

ʻĀpana hoʻoheheʻe kinoea nui.

Ka nānā 'ana i ke kinoea kinoea (FTIR spectroscopy).

Ka uku hoʻokahe ʻakomi i ka wā ulu.

3. Hoʻonui maikaʻi Crystal

Hoʻokomo ka ʻōnaehana i nā mea hou e hoʻomaikaʻi ai i ka maikaʻi kristal:

ʻO ka mea paʻa pani pani (0-100rpm programmable).

ʻenehana hoʻomalu pae palena kiʻekiʻe.

Pūnaehana kiaʻi defect in-situ (UV laser scattering).

ʻOkoʻa koʻikoʻi uku i ka wā ulu.

4. Ka 'Omomi a me ka Mana

Ka hoʻokō ʻana i ka meaʻai.

ʻO AI ka hoʻonui ʻana i ka hoʻonui ʻana i ka manawa maoli.

Ka nānā mamao a me ka diagnostics.

ʻO 1000+ ka hoʻopaʻa inoa ʻana i ka ʻikepili (mālama ʻia no 5 mau makahiki).

5. Nā hiʻohiʻona palekana a me ka hilinaʻi

ʻO ka pale ʻana i ka wela ma luna o ka wela ʻekolu.

Pūnaehana hoʻomaʻemaʻe ulia pōpilikia.

Hoʻolālā hale i helu ʻia e ka Seismic.

98.5% ka hōʻoia ʻana i ka wā hoʻomaha.

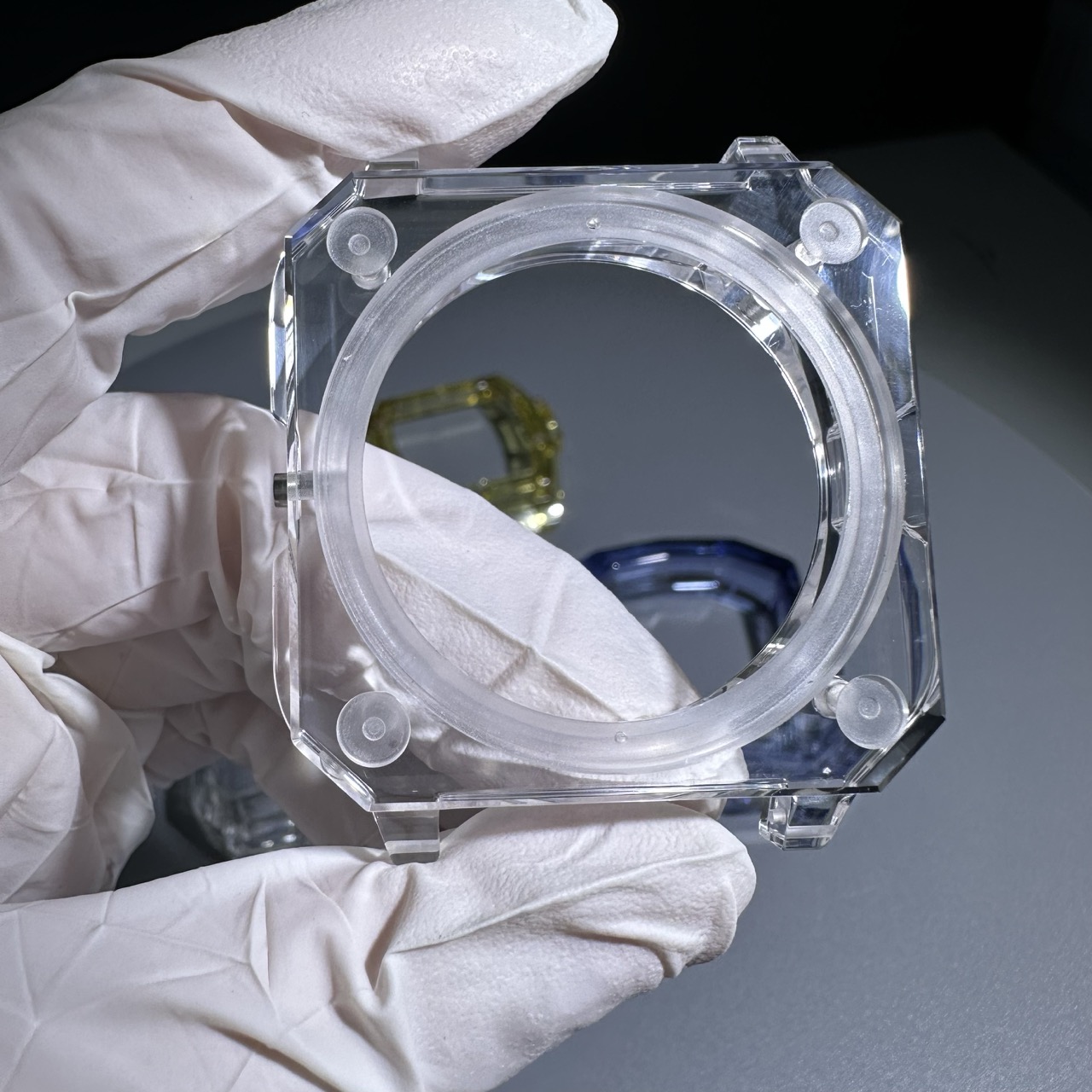

6. Hoʻolālā hiki ke hoʻonui ʻia

Hiki i ka hoʻolālā modular ke hoʻonui i ka hiki.

Kūpono me ka nui wafer 100mm a 200mm.

Kākoʻo i nā hoʻonohonoho kūpaʻa a me ke ākea.

Hoʻololi wikiwiki i nā ʻāpana no ka mālama ʻana.

7. Hoʻoikaika ikaika

30% haʻahaʻa haʻahaʻa ma mua o nā ʻōnaehana like.

Hoʻopaʻa ka ʻōnaehana hoʻōla wela i ka 60% o ka wela wela.

ʻO nā algorithms hoʻohana kinoea maikaʻi loa.

Nā koi o ka hale e hoʻokō i ka LEED.

8. Maikaʻi Versatility

Hoʻoulu i nā polytype SiC nui (4H, 6H, 3C).

Kākoʻo i nā ʻano conductive a me semi-insulating.

Hoʻokomo i nā ʻano hana doping like ʻole (N-type, P-type).

Kūpono me nā mea mua ʻē aʻe (e laʻa, TMS, TES).

9. Hoʻokō ʻana o ka ʻōnaehana vacuum

Pumi kumu: <1×10⁻⁶ Torr

Laki leak: <1×10⁻⁹ Torr·L/sec

ʻO ka māmā holo ʻana: 5000L/s (no SiH₄)

Ka hoʻomalu ʻana i ke kaomi ʻakomi i ka wā ulu

Hōʻike kēia kikoʻī ʻenehana piha i ka hiki o kā mākou ʻōnaehana hana i ka noiʻi a me ka hana ʻana i nā kristal SiC maikaʻi loa me ka ʻoihana alakaʻi kūlike a me ka hua. ʻO ka hui pū ʻana o ka mana pololei, ka nānā ʻana i mua, a me ka ʻenekinia ikaika e hana i kēia ʻōnaehana CVD i koho maikaʻi loa no ka R&D a me nā noi hana volume i nā uila uila, nā mea RF, a me nā noi semiconductor holomua.

Nā Pōmaikaʻi Nui

1. Hoʻonui Kiʻekiʻe Crystal

• ʻAʻohe haʻahaʻa haʻahaʻa ma lalo o <1000/cm² (4H-SiC)

• Kaulike doping <5% (6-inihi wafers)

• Ka maʻemaʻe kristal >99.9995%

2. Large-Size Production hiki

• Kākoʻo i ka ulu ʻana o ka wafer 8 iniha

• Kaulike anawaena >99%

• ʻokoʻa mānoanoa <±2%

3. Ka Mana Mana Pono

• Ka hoʻomalu ʻana o ka wela ± 1°C

• Ka pololei o ke kahe o ke kinoea ± 0.1sccm

• Ka pololei o ka mana kaomi ±0.1Torr

4. Hoʻoikaika ikaika

• 30% ʻoi aku ka maikaʻi o ka ikehu ma mua o nā ʻano hana maʻamau

• Ka ulu ulu a hiki i 50-200μm / h

• ka manawa hana o ka lako >95%

Nā noi nui

1. Nā Mea Hana Uila

6-inch 4H-SiC substrates no 1200V+ MOSFETs/diodes, e hōʻemi ana i nā poho hoʻololi e 50%.

2. 5G Kūkākūkā

Semi-insulating SiC substrates (resistivity >10⁸Ω·cm) no ke kahua kahua PA, me ka hookomo poho <0.3dB ma >10GHz.

3. Nā Kaʻa Hulihu Hou

Hoʻonui ka mana o ka mana ʻo Automotive-grade SiC i ka laulā EV e 5-8% a hoʻemi i ka manawa hoʻopiʻi e 30%.

4. PV Inverters

Hoʻonui nā substrates haʻahaʻa haʻahaʻa i ka hoʻololi ʻana ma mua o 99% ʻoiai e hōʻemi ana i ka nui o ka ʻōnaehana e 40%.

Nā lawelawe a XKH

1. Nā lawelawe hoʻoponopono

Hana ʻia nā ʻōnaehana CVD 4-8 iniha.

Kākoʻo i ka ulu ʻana o ke ʻano 4H / 6H-N, 4H / 6H-SEMI insulating type, etc.

2. Kākoʻo ʻenehana

ʻO ka hoʻomaʻamaʻa piha ʻana i ka hana a me ke kaʻina hana.

24/7 pane ʻenehana.

3. Hoʻoponopono Turnkey

Nā lawelawe hope-a-hope mai ka hoʻokomo ʻana i ka hōʻoia ʻana.

4. Mea lako

2-12 iniha SiC substrates/epi-wafers loaʻa.

Kākoʻo 4H/6H/3C polytypes.

Loaʻa nā mea hoʻokaʻawale nui:

A hiki i ka 8-iniha ka hiki ke ulu kristal.

20% ʻoi aku ka wikiwiki o ka ulu ʻana ma mua o ka awelika ʻoihana.

98% hilinaʻi pūnaewele.

Pūnaehana hoʻomalu naʻauao piha.