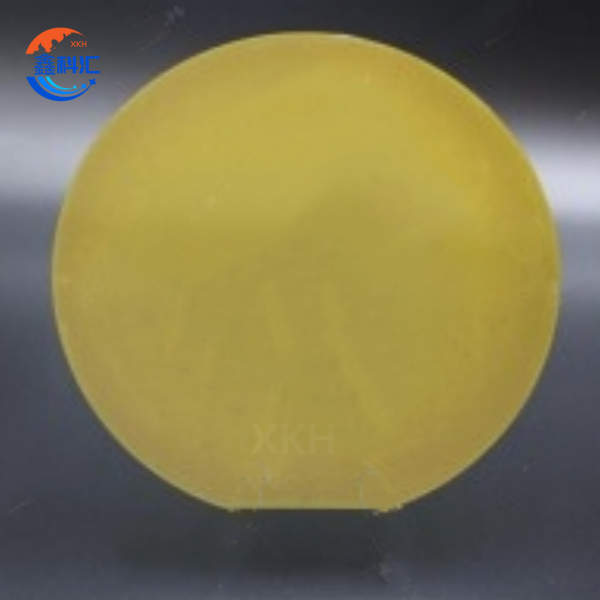

6 ʻīniha Conductive single crystal SiC ma polycrystalline SiC composite substrate Diameter 150mm P ʻano N ʻano

Nā palena ʻenehana

| Nui: | 6 iniha |

| anawaena: | 150 mm |

| mānoanoa: | 400-500 μm |

| Nā Palena Kiʻiʻoniʻoni Monocrystalline SiC | |

| Polytype: | 4H-SiC a i ʻole 6H-SiC |

| Hoʻopaʻa Doping: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| mānoanoa: | 5-20 μm |

| Palekana Pepa: | 10-1000 Ω/sq |

| Electron Mobility: | 800-1200 knm²/Vs |

| Hole Mobility: | 100-300 knm²/Vs |

| ʻO nā ʻāpana ʻāpana polycrystalline SiC Buffer Layer | |

| mānoanoa: | 50-300 μm |

| ʻO ka wela wela: | 150-300 W/m·K |

| Monocrystalline SiC Substrate Parameters | |

| Polytype: | 4H-SiC a i ʻole 6H-SiC |

| Hoʻopaʻa Doping: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| mānoanoa: | 300-500 μm |

| Ka nui o ka palaoa: | > 1 mm |

| ʻO ka ʻili ʻili: | < 0.3 mm RMS |

| Mea Mechanical & Uila | |

| ʻoʻoleʻa: | 9-10 Mohs |

| ʻO ka ikaika hoʻopili: | 3-4 GPa |

| ʻOi aku ka ikaika: | 0.3-0.5 GPa |

| Ka ikaika o ke kahua hoʻokaʻawale: | > 2 MV/cm |

| Ka huina hoʻomanawanui: | > 10 Mrad |

| Kū'ē hopena hanana hoʻokahi: | > 100 MeV·cm²/mg |

| ʻO ka wela wela: | 150-380 W/m·K |

| Kaulana Mahana Hana: | -55 a hiki i 600°C |

Nā ʻano nui

Hāʻawi ka 6-inch conductive monocrystalline SiC ma polycrystalline SiC composite substrate i kahi kaulike kūʻokoʻa o ka hoʻolālā waiwai a me ka hana, kūpono ia no ka koi ʻana i nā kaiapuni ʻoihana.

1.Cost-Effectiveness: ʻO ka polycrystalline SiC base e hoʻemi nui i nā kumukūʻai i hoʻohālikelike ʻia me ka monocrystalline SiC piha, ʻoiai ʻo ka monocrystalline SiC active layer e hōʻoia i ka hana o ka mīkini, kūpono no nā noi pili kālā.

2. Nā Pono Uila Nui: ʻO ka monocrystalline SiC layer e hōʻike ana i ka neʻe ʻana o ka mea lawe kiʻekiʻe (> 500 cm²/V·s) a me ka haʻahaʻa haʻahaʻa haʻahaʻa, e kākoʻo ana i ka hana kiʻekiʻe a me ka mana kiʻekiʻe.

3.High-Temperature Stability: ʻO ke kūpaʻa kiʻekiʻe kiʻekiʻe o SiC (> 600 ° C) e hōʻoia i ka paʻa o ka substrate composite ma lalo o nā kūlana koʻikoʻi, e kūpono ana i nā kaʻa uila a me nā noi kaʻa ʻoihana.

4.6-inch Standardized Wafer Size: Hoʻohālikelike ʻia me nā substrates 4-inch SiC kuʻuna, hoʻonui ka format 6-inch i ka hua chip ma mua o 30%, e hōʻemi ana i nā kumukūʻai o kēlā me kēia ʻāpana.

5.Conductive Design: Pre-doped N-type a i ʻole P-type papa e hōʻemi i nā ʻanuʻu implantation ion i ka hana ʻana i nā mea hana, hoʻomaikaʻi i ka hana pono a me ka hua.

6. Hoʻokele Thermal Superior: ʻO ka polycrystalline SiC base's thermal conductivity (~ 120 W/m·K) e pili ana i ka monocrystalline SiC, e hoʻoponopono pono i nā pilikia hoʻoheheʻe wela i nā mea mana kiʻekiʻe.

Hoʻonohonoho kēia mau hiʻohiʻona i ka 6-inch conductive monocrystalline SiC ma ka polycrystalline SiC composite substrate ma ke ʻano he hopena hoʻokūkū no nā ʻoihana e like me ka ikehu hou, ka halihali kaʻaahi, a me ka aerospace.

Nā noi kumu mua

ʻO ka 6-inch conductive monocrystalline SiC ma ka polycrystalline SiC composite substrate ua hoʻokomo maikaʻi ʻia ma kekahi mau kahua koi nui:

1.Electric Vehicle Powertrains: Hoʻohana ʻia i nā MOSFET SiC kiʻekiʻe a me nā diodes e hoʻomaikaʻi i ka pono o ka inverter a hoʻonui i ka nui o ka pila (e like me Tesla, BYD models).

2.Industrial Motor Drives: Hiki i nā modula mana kiʻekiʻe, hoʻololi-frequency, hoʻemi i ka ikehu i nā mīkini kaumaha a me nā makani makani.

3.Photovoltaic Inverters: Hoʻonui nā mea SiC i ka maikaʻi o ka hoʻololi ʻana o ka lā (> 99%), ʻoiai ʻo ka substrate composite e hoʻemi hou i nā kumukūʻai ʻōnaehana.

4.Rail Transportation: Hoʻohana ʻia i nā mea hoʻololi traction no ke kaʻa kaʻa kiʻekiʻe a me nā ʻōnaehana subway, e hāʻawi ana i ke kūpaʻa kiʻekiʻe-voltage (> 1700V) a me nā kumu kikoʻī.

5.Aerospace: He kūpono no nā ʻōnaehana uila uila a me nā kaʻa kaʻa kaʻa ʻenekini mokulele, hiki ke kū i nā wela wela a me ka radiation.

Ma ka hana pono, ua kūpono piha ka 6-inihi conductive monocrystalline SiC ma ka polycrystalline SiC composite substrate me nā kaʻina hana SiC maʻamau (e laʻa, lithography, etching), ʻaʻole koi i ka hoʻopukapuka kālā hou.

Nā lawelawe XKH

Hāʻawi ʻo XKH i ke kākoʻo piha no ka 6-inch conductive monocrystalline SiC ma ka polycrystalline SiC composite substrate, e uhi ana i ka R&D i ka hana nui:

1.Customization: Hiki ke hoʻololi ʻia ka mānoanoa o ka papa monocrystalline (5-100 μm), ka manaʻo doping (1e15–1e19 cm⁻³), a me ke ʻano aniani (4H/6H-SiC) e hoʻokō i nā koi o nā mea like ʻole.

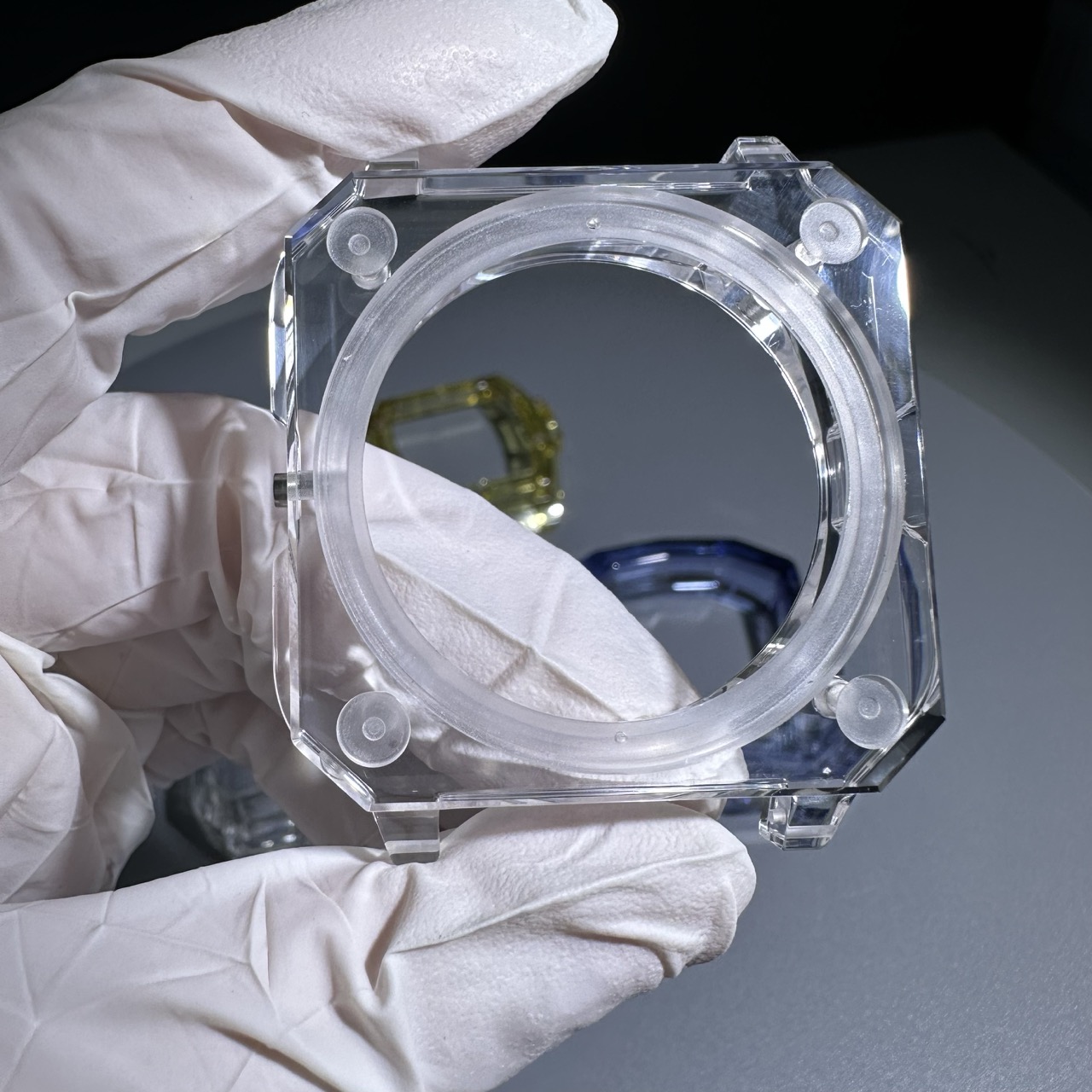

2.Wafer Processing: Hāʻawi nui i nā substrates 6-inch me ka ʻaoʻao hope thinning a me nā lawelawe metallization no ka hoʻohui plug-and-play.

3. Hōʻoia ʻenehana: Hoʻokomo ʻia ka nānā ʻana i ka crystallinity XRD, ka hoʻāʻo ʻana i ka Hall effect, a me ke ana ʻana i ke kūpaʻa wela no ka hoʻomaʻamaʻa ʻana i nā mea.

4.Rapid Prototyping: 2- a hiki i ka 4-inch samples (ka hana like) no nā keʻena noiʻi e hoʻolōʻihi i nā pōʻai hoʻomohala.

5.Failure Analysis & Optimization: Nā mea hoʻonā pae waiwai no ka hoʻoponopono ʻana i nā pilikia (e laʻa, epitaxial layer defects).

ʻO kā mākou misionari ka hoʻokumu ʻana i ka 6-inch conductive monocrystalline SiC ma ka polycrystalline SiC composite substrate e like me ke kumu kūʻai hoʻokō maikaʻi loa no ka uila uila SiC, e hāʻawi ana i ke kākoʻo hope-to-end mai ka prototyping a i ka hana volume.

Ka hopena

ʻO ka 6-inch conductive monocrystalline SiC ma ka polycrystalline SiC composite substrate e loaʻa ai ke koena holomua ma waena o ka hana a me ke kumukūʻai ma o kāna ʻano mono/polycrystalline hybrid hou. Ke hoʻonui nei nā kaʻa uila a me ka holomua ʻana o ka ʻOihana 4.0, hāʻawi kēia substrate i kahi kumu waiwai hilinaʻi no ka uila mana o ka hanauna e hiki mai ana. Hoʻokipa ʻo XKH i ka hui pū ʻana e ʻimi hou i ka hiki o ka ʻenehana SiC.