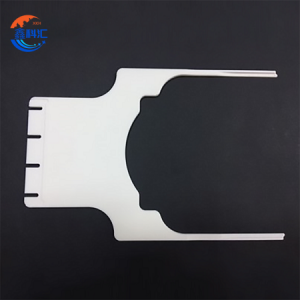

Alumina Ceramic End Effector / Fork Arm for Wafer and Substrate Handling

Kiʻi kikoʻī

ʻO ka manaʻo nui o ka Alumina Ceramic End Effector

ʻO ka Alumina Ceramic End Effector, i kapa ʻia ʻo ka lima fork ceramic a i ʻole ka ceramic gripper, he mea koʻikoʻi i hoʻohana ʻia i ka robotic automation a me nā laina hana maʻemaʻe. Hoʻokomo ʻia ʻo Alumina Ceramic End Effector ma ka lima robotic ma ke ʻano he kikowaena hope loa me ka huahana, kuleana no ka ʻohi, paʻa ʻana, aligning, a me ka hoʻoili ʻana i nā ʻāpana koʻikoʻi e like me nā wafers silicon, panel aniani, a i ʻole nā mea microelectronic.

Hana ʻia mai ka ultra-pure alumina ceramic (Al2O3), hāʻawi kēia lima lāʻau i kahi hopena maʻemaʻe a paʻa loa no nā kaiapuni kahi hiki ʻole ke ʻae ʻia ka hoʻohaumia metala, ka hoʻololi ʻana i ka plastic, a i ʻole ka hana ʻana.

Mea Pono - No ke aha ʻo Alumina

E pili ana i ka Alumina Ceramic End Effector,Alumina (Al2O3) kekahi o nā mea i hoʻokumu ʻia a hilinaʻi.ʻenehana ʻenekinia kiʻekiʻe. ʻO ka papa a mākou e hoʻohana ai (≥99.5% maʻemaʻe) hāʻawi i kahi hui kūʻokoʻa o nā ʻano kino a me nā ʻano kemika e hoʻolilo iā ia i mea koho no ka semiconductor a me nā noi vacuum:

-

ʻoʻoleʻa loa- Me ka helu paʻakikī Mohs o 9, hāʻawi ia i ka lōʻihi lōʻihi a me ka pale ʻana.

-

ʻO ka hoʻomanawanui wela- Hoʻomau i ka pono o ka hoʻolālā ma mua o 1600 ° C, ʻoi aku ka maikaʻi o nā mea metala a me nā polymer.

-

Hoʻopili uila- Hoʻopau i ka buildup static a hāʻawi i ka pale dielectric piha.

-

Ka palekana kemika- ʻAʻole i hoʻopilikia ʻia e nā waikawa, alkalis, nā kinoea plasma, a me nā hoʻonā hoʻomaʻemaʻe hoʻomaʻemaʻe.

-

Hiki ke hoʻohaʻahaʻa haʻahaʻa loa– Non-outgassing, haʻahaʻa-friction ili e hōʻemi ana i ka hoʻokuʻu ʻana o nā ʻāpana i loko o nā lumi maʻemaʻe.

Hāʻawi kēia mau hiʻohiʻona i ka alumina ceramic end effectors e hana me ka hala ʻole i loko o nā kaiapuni koʻikoʻi, kiʻekiʻe.

Nā noi kumu o ka Alumina Ceramic End Effector

ʻO ka versatility o nā lima alumina ceramic end effectorfork he mea nui ia i nā ʻoihana ʻenehana kiʻekiʻe.

-

Nā ʻōnaehana lawe wafer Semiconductor- Ke hoʻoneʻe paʻa i nā wafer silika mai ke kaʻina hana i ka hana me ka ʻole o nā micro-scratches.

-

ʻO ka hana hōʻike papa pālahalaha- Ka lawelawe ʻana i nā pani aniani palupalu no ka OLED, LCD, a i ʻole ka hana microLED.

-

ʻO ka hana ʻana o Photovoltaic (PV).- Ke kākoʻo nei i ka hoʻouka ʻana a me ka wehe ʻana o ka wafer solar ma lalo o nā pōkā robotic kiʻekiʻe.

-

ʻO ka hui ʻokoʻa a me ka uila- Hoʻopili i nā ʻāpana liʻiliʻi e like me nā sensors, resistors, a me nā ʻāpana liʻiliʻi.

-

ʻO ka mīkini hoʻomaʻemaʻe a me ka lumi hoʻomaʻemaʻe- Ke hana nei i nā hana pololei i nā kūlana hoʻomaʻemaʻe ultra-maʻemaʻe.

I kēlā me kēia hiʻohiʻona, hāʻawi ka Alumina Ceramic End Effector i ka pilina koʻikoʻi ma waena o ka robotic automation a me ka neʻe ʻana o ka huahana.

Nā koho hoʻolālā a me ka hoʻoponopono ʻana o ka Alumina Ceramic End Effector

Loaʻa i kēlā me kēia laina hana nā koi kūikawā. No laila, hāʻawi mākou i nā hoʻonā Alumina Ceramic End Effector i hana ʻia no nā nui wafer like ʻole, nā ʻōnaehana robotic, a me nā ʻano hana:

Hoʻohālikelike Wafer: Hoʻohana i nā wafers mai 2 "a 12" a hiki ke hoʻonui ʻia no nā ʻāpana maʻamau.

Nā koho Geometry: ʻO ka ʻōpala hoʻokahi, ka ʻāpana ʻelua, ka nui-slot, a i ʻole nā ʻano hana maʻamau me nā recesses i hoʻohui ʻia.

Ka hoʻohana ʻana i ka ʻūhā: ʻO nā ʻauwaʻa hoʻoheheʻe ʻana i koho ʻia no ke kākoʻo wafer contactless.

Nā mea hoʻopaʻa hoʻopaʻa ʻana: ʻO nā lua bolt maʻamau, nā flanges, a i ʻole nā manaʻo slotted e kūpono i kekahi lima robotic.

Hoʻopau i ka ʻili: Nā ʻili i hoʻomaʻamaʻa ʻia a i ʻole ka hoʻopau ʻia (i lalo i Ra <0.15 μm).

Nā ʻaoʻao ʻaoʻao: Chamfered a poʻe ʻaoʻao no ka pale wafer kiʻekiʻe.

Hiki i kā mākou hui ʻenekinia Alumina Ceramic End Effector ke hana mai nā kiʻi CAD o nā mea kūʻai aku a i ʻole nā ʻāpana hoʻohālike, e hōʻoia ana i ka hoʻohui pono ʻana i nā ʻōnaehana automation.

Nā Pōmaikaʻi Koʻikoʻi o nā Alumina Ceramic End Effectors

| Hiʻona | No ke aha ia mea |

|---|---|

| ʻO ke kiko kiko | Mālama i ka hoʻopololei piha ʻana i nā pōʻai holoʻokoʻa kiʻekiʻe. |

| Hoʻohaumia ʻole | ʻAʻohe mea e hoʻopuka ai, e hālāwai me nā pono lumi hoʻomaʻemaʻe. |

| He wela a me ka corrosion proof | Hoʻomanawanui i nā ʻanuʻu hana ʻino a me nā haʻalulu wela. |

| ʻAʻohe uku paʻa | Mālama i nā wafers a me nā ʻāpana mai ka pilikia electrostatic. |

| Māmā akā ʻoʻoleʻa | Hāʻawi i ka ʻoʻoleʻa kiʻekiʻe me ka ʻole o ka hoʻokau ʻana i ka ukana lima robotic. |

| Hoʻonui i ke ola lawelawe | ʻOi aku ka maikaʻi o nā lima metala a me ka polymer i ke ola a me ka hilinaʻi. |

Hoʻohālikelike Mea o ka Alumina Ceramic End Effector

| ʻAno | Lima Puka Puka | Aluminum/Metala Puka Lima | ʻO ka lima ʻokalakala alumina |

|---|---|---|---|

| ʻoʻoleʻa | Haʻahaʻa | Kauwaena | Kiekie loa |

| Kaulana wela | ≤ 150°C | ≤ 500°C | A hiki i 1600°C |

| Paʻa Kemika | ʻilihune | Kaumaha | maikaʻi loa |

| Ka helu o ka lumi hoʻomaʻemaʻe | Haʻahaʻa | Awelika | Kūpono no ka Papa 100 a ʻoi aku paha |

| ʻAʻahu Kūʻē | kaupalena | Maikaʻi loa | Kūlana |

| Papa Hoʻoponopono | Kaumaha | kaupalena | Nui |

Nīnau pinepine (FAQ) o Alumina Ceramic End Effector

Q1: He aha ka mea e ʻokoʻa ai ka hopena hopena alumina ceramic mai kahi metala?

A1:ʻAʻole like me ka alumini a i ʻole nā lima kila, ʻaʻole e hoʻopōʻino, hoʻololi, a hoʻokomo ʻia nā ion metala i loko o nā kaʻina semiconductor. Paʻa paʻa ma lalo o nā kūlana koʻikoʻi a hoʻokuʻu ʻole i nā ʻāpana.

Q2: Hiki i kēia mau Alumina Ceramic End Effector ke hoʻohana i nā keʻena kiʻekiʻe-vacuum a me nā keʻena plasma?

A2:ʻAe. ʻO ka alumina keramikanon-outgassinga kūpaʻa i ka plasma, kahi mea i makemake ʻia no ka hana ʻana a me nā mea hana etching.

Q3: Pehea ka hana maʻamau o kēia mau lima lāʻau Alumina Ceramic End Effector?

A3:Hiki i kēlā me kēia ʻāpanahoʻopilikino piha—me ke ʻano, nā puka, nā puka hoʻoheheʻe, ke ʻano kau ʻana, a me ka pau ʻana o ka lihi—e kūlike i nā koi o kāu ʻōnaehana robotic.

Q4: He palupalu lākou?

A4:ʻOiai he palupalu maoli ka ceramic, kā mākou ʻenekinia hoʻolālā e puʻunaue like i ka ukana a hōʻemi i nā wahi koʻikoʻi. Ke mālama pono ʻia, ʻoi aku ka nui o ke ola o ka lawelawe ma mua o nā mea metala a i ʻole nā polymer.

E pili ana iā mākou

Hoʻokumu ʻo XKH i ka hoʻomohala ʻenehana kiʻekiʻe, ka hana ʻana, a me ke kūʻai ʻana i nā aniani optical kūikawā a me nā mea aniani hou. Hāʻawi kā mākou huahana i nā uila uila, nā mea hoʻohana uila, a me ka pūʻali koa. Hāʻawi mākou i nā ʻāpana optical Sapphire, nā uhi kelepona kelepona paʻa, Ceramics, LT, Silicon Carbide SIC, Quartz, a me nā wafer kristal semiconductor. Me ka ʻike akamai a me nā mea hana ʻoki ʻoki, ʻoi aku mākou i ka hoʻoili huahana maʻamau ʻole, me ka manaʻo e lilo i alakaʻi optoelectronic material high-tech ʻoihana.