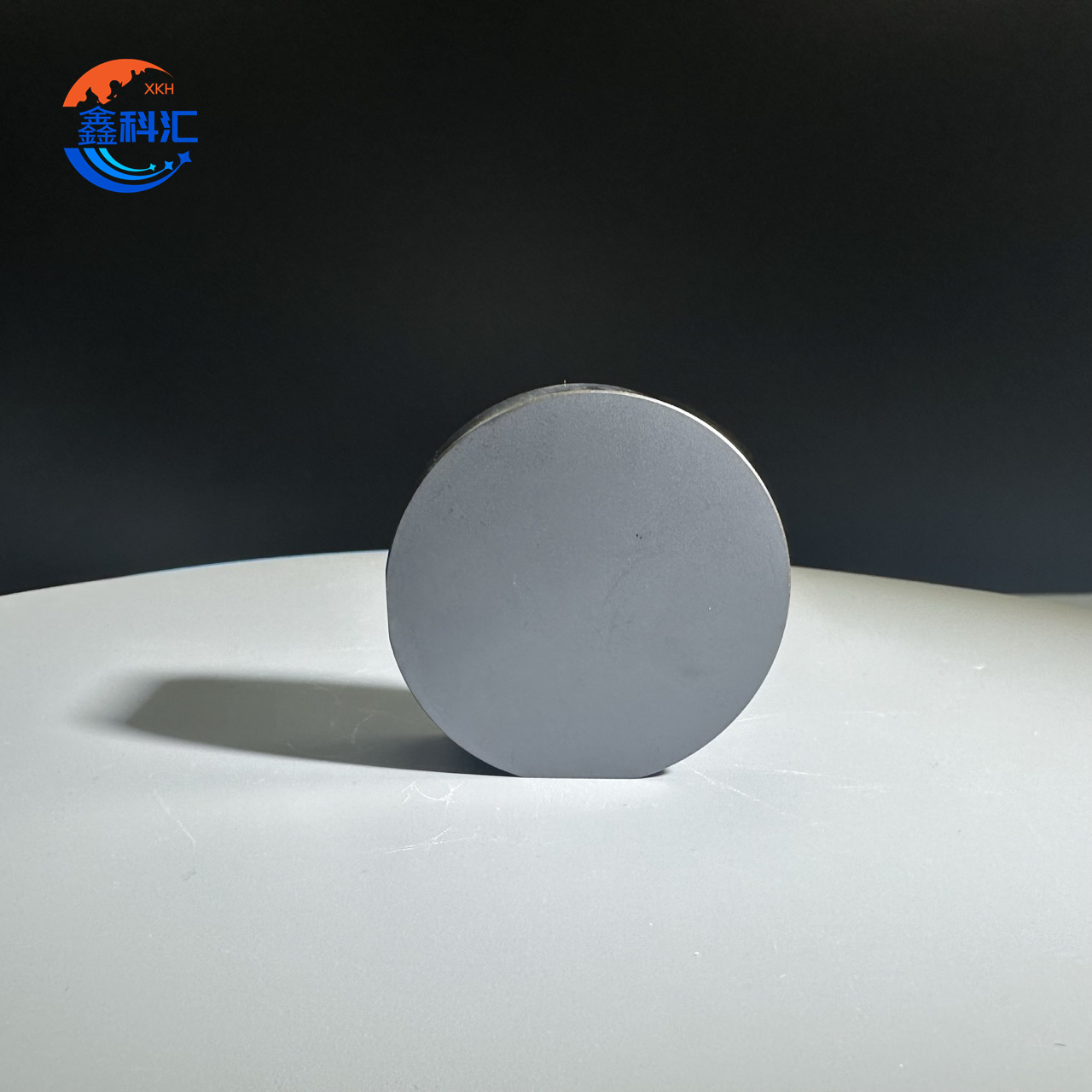

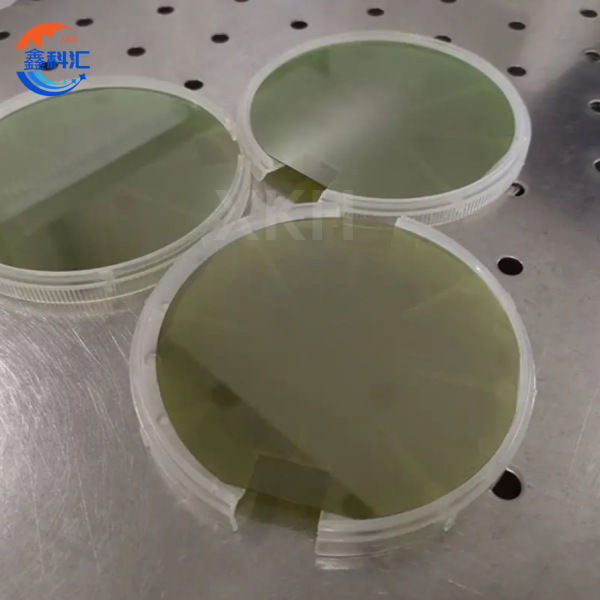

Kūʻai N Type SiC Seed Substrate Dia153/155mm No nā Electronics Power

Hoʻolauna

Hoʻohana ʻia nā kumulāʻau Silicon Carbide (SiC) ma ke ʻano he kumu kumu no nā semiconductor o nā hanauna ʻekolu, i ʻike ʻia e ko lākou conductivity thermal kiʻekiʻe, ʻoi aku ka ikaika o ke kahua uila, a me ka mobility electron kiʻekiʻe. Hoʻolilo kēia mau waiwai iā lākou i mea nui no ka uila uila, nā mea RF, nā kaʻa uila (EVs), a me nā noi ikehu hou. Hoʻolaha ʻo XKH i ka R&D a me ka hana ʻana i nā substrate hua SiC kiʻekiʻe, e hoʻohana ana i nā ʻenehana ulu kristal holomua e like me Physical Vapor Transport (PVT) a me High-Temperature Chemical Vapor Deposition (HTCVD) e hōʻoia i ka maikaʻi crystalline alakaʻi i ka ʻoihana.

Hāʻawi ʻo XKH i nā substrate hua SiC 4-ʻīniha, 6-ʻīniha, a me 8-ʻīniha me ka doping N-type/P-type maʻamau, e loaʻa ana i nā pae resistivity o 0.01-0.1 Ω·cm a me nā dislocation densities ma lalo o 500 cm⁻², e hoʻolilo iā lākou i mea kūpono no ka hana ʻana i nā MOSFET, Schottky Barriers. ʻO kā mākou kaʻina hana i hoʻohui pono ʻia e uhi i ka ulu ʻana o ka kristal, ka ʻoki ʻana i ka wafer, ka polishing, a me ka nānā ʻana, me ka mana hana o kēlā me kēia mahina ma mua o 5,000 wafers e hoʻokō i nā koi like ʻole o nā keʻena noiʻi, nā mea hana semiconductor, a me nā hui ikehu hou.

Eia hou, hāʻawi mākou i nā hoʻonā maʻamau, me:

ʻO ka hana maʻamau o ke aniani (4H-SiC, 6H-SiC)

Doping kūikawā (Aluminium, Nitrogen, Boron, etc.)

ʻO ka poʻi maʻemaʻe loa (Ra < 0.5 nm)

Kākoʻo ʻo XKH i ka hoʻoili ʻana i nā laʻana, nā kūkākūkā ʻenehana, a me nā prototyping liʻiliʻi e hāʻawi i nā ʻōnaehana substrate SiC i hoʻopaʻa ʻia.

Nā palena ʻenehana

| Wafer anoano silikoni | |

| Polytype | 4H |

| Ua hewa ka hoʻonohonoho ʻana o ka ʻili | 4° i ka<11-20>±0.5º |

| Kū'ē | hoʻopilikino |

| Anawaena | 205±0.5mm |

| mānoanoa | 600±50μm |

| ʻoʻoleʻa | CMP, Ra≤0.2nm |

| Micropipe Density | ≤1 ea/cm2 |

| Nā ʻōpala | ≤5, Ka nui Length≤2 * Anawaena |

| Nā ʻāpana lihi/indents | ʻAʻohe |

| Hoailona laser mua | ʻAʻohe |

| Nā ʻōpala | ≤2, Ka huina Length≤Diameter |

| Nā ʻāpana lihi/indents | ʻAʻohe |

| Nā wahi polytype | ʻAʻohe |

| Hōʻailona laser hope | 1mm (mai ka lihi luna) |

| Kaulana | Chamfer |

| Hoʻopili ʻia | ʻO ka pīkī wafer nui |

Nā Pānaʻi Hua SiC - Nā ʻano nui

1. Na Waiwai Kino Kuehie

· Kiʻekiʻe thermal conductivity (~ 490 W/m·K), ʻoi aku ka nui ma mua o ke silicona (Si) a me ka gallium arsenide (GaAs), i mea kūpono no ka hoʻoluʻu ʻana i ka mana kiʻekiʻe.

· Hoʻohaʻahaʻa i ka ikaika kahua (~ 3 MV/cm), hiki i ka hana paʻa ma lalo o nā kūlana kiʻekiʻe-voltage, koʻikoʻi no nā mea hoʻohuli EV a me nā modula mana ʻoihana.

· ʻAkea bandgap (3.2 eV), e hōʻemi ana i ka leakage au i nā wela kiʻekiʻe a hoʻonui i ka hilinaʻi o ka mea hana.

2. ʻOi aku ka maikaʻi o ka Crystalline

· Hoʻemi ka ʻenehana ulu hybrid PVT + HTCVD i nā hemahema micropipe, e mālama ana i ka nui o ka dislocation ma lalo o 500 cm⁻².

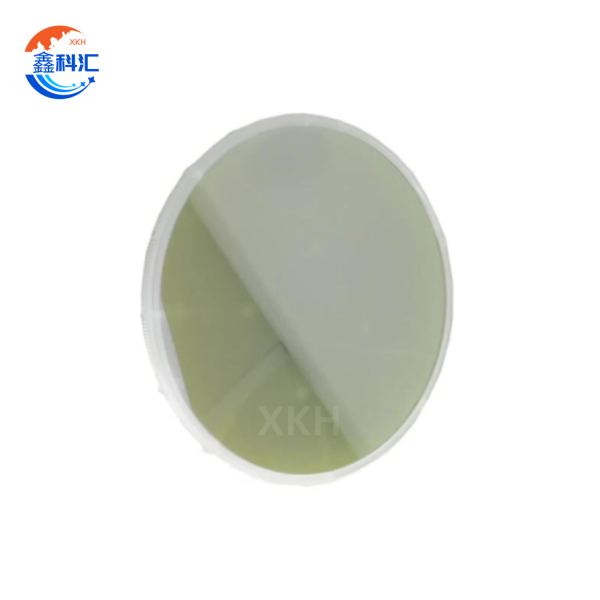

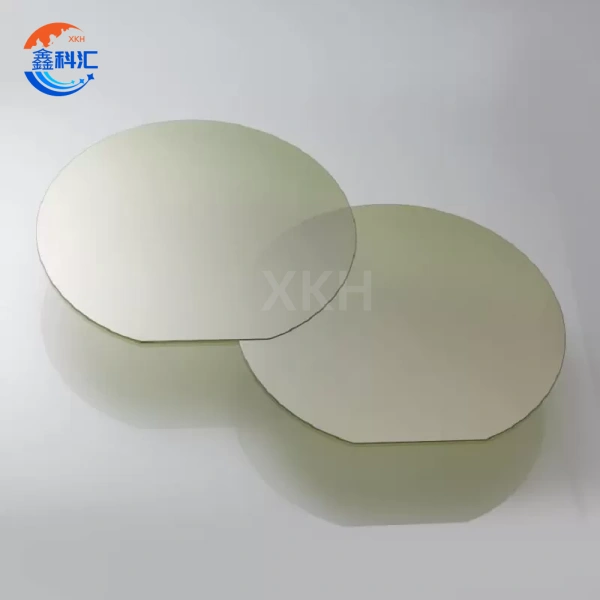

· Wafer bow/warp <10 μm and surface roughness Ra <0.5 nm, e hōʻoia ana i ka launa pū me ka lithography kiʻekiʻe a me nā kaʻina hana hoʻoheheʻe kiʻiʻoniʻoni.

3. Nā Koho Doping ʻokoʻa

·N-type (Nitrogen-doped): Haʻahaʻa resistivity (0.01-0.02 Ω·cm), optimized no kiʻekiʻe-frequency RF mea.

· P-type (Aluminum-doped): He kūpono no nā MOSFET mana a me nā IGBT, e hoʻomaikaʻi ana i ka neʻe ʻana o ka mea lawe.

· Semi-insulating SiC (Vanadium-doped): Resistivity > 10⁵ Ω·cm, i hoʻopili ʻia no nā modula mua 5G RF.

4. Paʻa Kaiapuni

· Ke kū'ē i ka wela kiʻekiʻe (> 1600 ° C) a me ka paʻakikī o ka radiation, kūpono no ka aerospace, nā lako nuklea, a me nā wahi ʻē aʻe.

ʻO nā mea kanu SiC - Nā noi mua

1. Mea uila mana

· Nā Kaʻa Uila (EV): Hoʻohana ʻia i nā mea hoʻoili ma luna o ka papa (OBC) a me nā mea hoʻohuli e hoʻomaikaʻi i ka pono a hōʻemi i nā koi hoʻokele wela.

· Nā Pūnaehana Mana Hana: Hoʻonui i nā mea hoʻohuli kiʻi photovoltaic a me nā grids akamai, e loaʻa ana> 99% ka pono hoʻololi mana.

2. Nā mea hana RF

· 5G Base Stations: Semi-insulating SiC substrates hiki ke GaN-on-SiC RF power amplifiers, kākoʻo i ka alapine kiʻekiʻe, ka mana kiʻekiʻe.

Nā Satellite Communications: ʻO nā hiʻohiʻona haʻahaʻa haʻahaʻa e kūpono i nā mea hawewe millimeter.

3. Hiki ke hoʻohou i ka ikehu a me ka mālama ikehu

· Mana Mana: Hoʻonui nā SiC MOSFET i ka hana hoʻololi DC-AC me ka hoʻemi ʻana i nā kumukūʻai ʻōnaehana.

· Energy Storage Systems (ESS): Optimizes bidirectional converters a hoʻonui i ke ola pākaukau.

4. Palekana & Aerospace

· Pūnaehana Radar: Hoʻohana ʻia nā mea mana kiʻekiʻe SiC i nā radar AESA (Active Electronically Scanned Array).

· Spacecraft Power Management: He mea koʻikoʻi nā substrate SiC pale i ka radiation no nā mikiona hohonu.

5. Nā ʻenehana noiʻi a me nā ʻenehana hou

· Quantum Computing: Hiki iā SiC maʻemaʻe kiʻekiʻe ke noiʻi spin qubit.

· Nā Kiʻekiʻe-Temperature Sensors: Hoʻohana ʻia i ka ʻimi ʻaila a me ka nānā ʻana i ka reactor nuklea.

ʻO nā mea kanu SiC - Nā lawelawe XKH

1. Nā Pōmaikaʻi Hoʻolako

· Hoʻohui paʻa i ka hana ʻana: Ka mana piha mai ka pauka SiC maʻemaʻe kiʻekiʻe i nā wafers i hoʻopau ʻia, e hōʻoia ana i nā manawa alakaʻi o 4-6 mau wiki no nā huahana maʻamau.

· Ka hoʻokūkū kumu kūʻai: Hiki i nā ʻoihana hoʻokele waiwai ke hāʻawi i ke kumu kūʻai haʻahaʻa 15-20% ma mua o nā mea hoʻokūkū, me ke kākoʻo ʻana i nā ʻaelike lōʻihi (LTA).

2. Nā lawelawe hoʻoponopono

· Ka hoʻonohonoho ʻana i ka kristal: 4H-SiC (maʻamau) a i ʻole 6H-SiC (nā noi kūikawā).

· Doping optimization: Hana ʻia nā waiwai N-type/P-type/semi-insulating.

· Hoʻomaʻamaʻa kiʻekiʻe: CMP polishing a me ka epi-ready surface treatment (Ra <0.3 nm).

3. Kākoʻo ʻenehana

· Hoʻāʻo manuahi manuahi: Loaʻa i ka XRD, AFM, a me nā hōʻike ana hopena Hall.

· Ke kōkua hoʻohālike polokalamu: Kākoʻo i ka ulu ʻana o ka epitaxial a me ka hoʻolālā ʻana i nā mea hana.

4. Pane wikiwiki

· Haʻahaʻa-volume prototyping: Ka liʻiliʻi loa o 10 wafers, hāʻawi 'ia i loko o 3 pule.

· Nā loina o ke ao holoʻokoʻa: Nā hui pū me DHL a me FedEx no ka lawe ʻana i kēlā me kēia puka.

5. Hōʻoia maikaʻi

· Nānā kaʻina hana piha: Uhi i ka topography X-ray (XRT) a me ka nānā ʻana i nā hemahema.

· Nā palapala hōʻoia o ka honua: Kūlike me nā kūlana IATF 16949 (automotive-grade) a me AEC-Q101.

Ka hopena

ʻOi aku ka maikaʻi o nā kumulāʻau SiC o XKH i ka maikaʻi crystalline, ka paʻa o ke kaulahao hoʻolako, a me ka maʻalahi o ka hoʻoponopono ʻana, ka lawelawe ʻana i nā uila uila, nā kamaʻilio 5G, ka ikehu hou, a me nā ʻenehana pale. Ke hoʻomau nei mākou i ka hoʻomohala ʻana i ka ʻenehana hana nui 8-inch SiC e alakaʻi i ka ʻoihana semiconductor ʻekolu o ka hanauna i mua.