ʻO ka mea hana kiʻekiʻe Alumina Ceramic End Effector (Fork Arm) no ka Semiconductor a me ka lumi hoʻomaʻemaʻe.

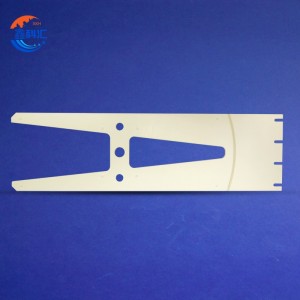

Kiʻi kikoʻī

Hoʻolauna Huahana

ʻO ka Alumina Ceramic End Effector, i kapa ʻia ʻo ia he ceramic fork arm a i ʻole robotic ceramic lima, he mea hoʻohana kiʻekiʻe kiʻekiʻe i hoʻolālā ʻia no nā ʻōnaehana automated i semiconductor, photovoltaic, panel display, a me nā ʻenehana hoʻomaʻemaʻe kiʻekiʻe. Hoʻolālā ʻia ia e hāʻawi i ke kūpaʻa wela ʻokoʻa, ka rigidity mechanical, a me ke kūpaʻa kemika, hāʻawi i ka lawe maʻemaʻe, hilinaʻi, a palekana hoʻi o nā mea koʻikoʻi e like me nā wafers silika, nā substrate aniani, a me nā ʻāpana uila uila.

E like me ke ʻano o ka robotic hopena hopena, ʻo kēia ʻāpana seramika ka mea hope loa ma waena o ka ʻōnaehana automation a me ka mea hana. He koʻikoʻi koʻikoʻi ia i ka hoʻololi pololei ʻana, ka hoʻonohonoho ʻana, ka hoʻouka ʻana a me ka hoʻonohonoho ʻana i nā hana i loko o nā lumi maʻemaʻe a me nā kaiapuni.

Nānā Mea Manaʻo – Alumina Ceramic (Al₂O₃)

ʻO ka alumina ceramic kahi mea paʻa paʻa a me ke kemika inert ʻenehana seramika i ʻike ʻia no kāna mau mea mīkini a me nā waiwai uila. ʻO ka alumina maʻemaʻe kiʻekiʻe (≥ 99.5%) i hoʻohana ʻia i kēia mau hopena hopena e hōʻoia:

-

Paʻa kiʻekiʻe (Mohs 9): ʻO ka lua wale nō i ke daimana, hāʻawi ka alumina i ke kūpaʻa ʻoi loa.

-

Hiki ke wela kiʻekiʻe: Mālama i ka pono o ka hale ma luna o 1600°C.

-

ʻO ka inertness kemika: Kūleʻa i nā ʻakika, alkalis, solvents, a me nā kaiapuni etching plasma.

-

Hoʻopili uila: Me ka ikaika dielectric kiʻekiʻe a me ka poho dielectric haʻahaʻa.

-

Hoʻonui wela haʻahaʻa: E hōʻoia i ka paʻa ʻana o ka dimensional i nā kaiapuni paikikala wela.

-

Haʻahaʻa haʻahaʻa haʻahaʻa: Pono no ka hoʻokō ʻana o ka lumi maʻemaʻe (Papa 10 a i ka Papa 1000).

ʻO kēia mau hiʻohiʻona e hana i ka alumina ceramic i kūpono no nā hana koʻikoʻi i loko o nā ʻoihana koʻikoʻi.

Nā noi hana

Hoʻohana nui ʻia ka alumina ceramic end effector i nā kaʻina hana ʻenehana kiʻekiʻe, ʻoiai kahi e hāʻule pōkole ai nā mea metala a i ʻole nā mea palaka ma muli o ka hoʻonui ʻana o ka wela, ka hoʻohaumia, a me nā pilikia corrosion. Loaʻa nā kahua noi nui:

- Hoʻoili wafer semiconductor

- ʻO ka hoʻouka ʻana a me ka wehe ʻana o nā ʻōnaehana Photolithography

- Hoʻohana ʻia ka substrate aniani ma nā laina OLED a me LCD

- ʻO ka hoʻoili ʻana o ka wafer silikona crystalline i ka hana ʻana o nā cell solar

- ʻO ka nānā ʻana i ka optical a i ʻole microelectronic

- Ka lawe laʻana i loko o nā labs analytical a biomedical

- Pūnaehana hoʻoheheʻe kaiapuni

ʻO kona hiki ke hana me ka ʻole o ka hoʻokomo ʻana i nā ʻāpana a i ʻole ka uku static he mea nui ia no nā hana robotic pololei i ka automation lumi maʻemaʻe.

Nā hiʻohiʻona hoʻolālā & hoʻopilikino

Hoʻonohonoho ʻia kēlā me kēia hopena hopena ceramic e kūpono i kahi lima robotic kikoʻī a i ʻole ʻōnaehana lawelawe wafer. Kākoʻo mākou i ka hoʻoponopono piha ma muli o:

-

Hoʻohālikelike ka nui o ka wafer: 2", 4", 6", 8", 12" a oi

-

Geometry a me ka hakahaka: Hoʻokomo i ka paʻa lihi, kākoʻo ʻaoʻao hope, a i ʻole nā hoʻolālā wafer notched

-

Nā awa ʻūhā: ʻO nā puka ʻūhā i hoʻohui ʻia a i ʻole nā kahawai no ka hoʻopili ʻole ʻana

-

Hoʻonohonoho kau ʻana: Nā puka, nā kaula, nā ʻīpuka i hoʻohālikelike ʻia i ka flange mea hana hope o kāu robot

-

Lapaʻau ʻili: Hoʻopiʻi ʻia, hoʻopaʻa ʻia, a i ʻole ka hoʻopau ʻāina maikaʻi (Ra <0.2 µm loaʻa)

-

Palekana lihi: Nā kihi poepoe a i ʻole chamfering e pale aku i ka pōʻino wafer

Ma ka hoʻohana ʻana i nā kiʻi CAD a i ʻole nā hiʻohiʻona 3D i hāʻawi ʻia e nā mea kūʻai aku, hiki i kā mākou mea ʻenekini ke hoʻopaʻa i kēlā me kēia lima fork no ke kaumaha, ikaika, a me ka maʻemaʻe.

ʻO nā mea maikaʻi o nā mea hoʻopau hope Ceramic

| Hiʻona | Pōmaikaʻi |

|---|---|

| Kiekie Mechanical Rigidity | E mālama i ka pololei dimensional ma lalo o nā mana hoʻouka robotic |

| Hana wela maikaʻi | Hana hilinaʻi ʻia ma nā wahi kiʻekiʻe a i ʻole plasma |

| ʻO ka hoʻohaumia metala ʻole | ʻAʻohe pilikia o ka hoʻohaumia ʻana i ka ion i ka hana semiconductor koʻikoʻi |

| Ili Pilikino Haʻahaʻa | Hoʻemi i ka pōʻino ma luna o ka wafer a i ʻole ke aniani substrates |

| Anti-Static a me Non-Magnetic | ʻAʻole ia e huki i ka lepo a i ʻole e hoʻopili i nā ʻāpana magnetic-sensitive |

| Ola Hana lōʻihi | ʻOi aku ka maikaʻi o ka hoʻohana ʻana i ka pale ʻana i nā pōʻai automation kiʻekiʻe |

| Hoʻolikelike-Maʻemaʻe | Kūpono no nā lumi maʻemaʻe ISO 14644 (Papa 100 a ma lalo) |

Hoʻohālikelike ʻia me nā lima plastic a alumini paha, hāʻawi ka alumina ceramic i ka hoʻomaikaʻi maikaʻi ʻana i ke kino a me ke kūpaʻa kino me ka liʻiliʻi o ka mālama pono.

| Waiwai | Lima Metala | Lima ʻili | ʻO ka Lima Ceramic Alumina |

|---|---|---|---|

| ʻoʻoleʻa | Kaumaha | Haʻahaʻa | Kiʻekiʻe loa (Mohs 9) |

| Paʻa wela | ≤ 500°C | ≤ 150°C | ≥ 1600°C |

| Palekana Kemika | Kaumaha | ʻilihune | maikaʻi loa |

| Pono ka lumi hoʻomaʻemaʻe | Kauwaena | Haʻahaʻa | Kiekie loa |

| ʻAʻahu Kūʻē | Kauwaena | Haʻahaʻa | Kūlana |

| Ka ikaika dielectric | Haʻahaʻa | Kauwaena | Kiʻekiʻe |

| Mīkini Mīkini Pono | kaupalena | Kaumaha | Kiʻekiʻe (± 0.01mm hiki ke hiki) |

Nā Kūlana ʻenehana

| ʻĀpana | Waiwai |

|---|---|

| Mea waiwai | Alumina maʻemaʻe kiʻekiʻe (≥ 99.5%) |

| Ka Mahana Hana | A hiki i 1600°C |

| ʻAole ʻili | Ra ≤ 0.2 µm (koe) |

| Nā Nui Wafer kūpono | 2" a hiki i ka 12" a maʻamau |

| Hoʻomanawanui Palahalaha | ±0.01 mm (pili i ka noi) |

| Kākoʻo ʻūhā ʻūhā | Nā ala koho, hiki ke hoʻololi ʻia |

| Nā koho kau ʻana | ʻO nā puka paʻa, nā flange, nā puka puka |

Nā nīnau i nīnau pinepine ʻia (FAQ)

Q1: Hiki ke hoʻohui ʻia ka hopena hopena i nā ʻōnaehana robotic i kēia manawa?

A1:ʻAe. Kākoʻo mākou i ka hana maʻamau e pili ana i kāu interface robotic. Hiki iā ʻoe ke hoʻouna iā mākou i kahi kiʻi CAD a i ʻole nā ana flange no ka hoʻoponopono pololei ʻana.

Q2: E haki maʻalahi nā lima seramika i ka wā e hoʻohana ai?

A2:ʻOiai he palupalu ka ceramic ma ke ʻano, hoʻohana kā mākou mau hoʻolālā i ka geometry i hoʻopaʻa ʻia e hōʻemi i ke koʻikoʻi koʻikoʻi. Ma lalo o nā kūlana hoʻohana kūpono, hāʻawi lākou i ke ola lawelawe ʻoi aku ka lōʻihi ma mua o ka metala a i ʻole ka plastic.

Q3: Hiki paha ke hoʻohana i kēia i loko o nā keʻena etching ultra-high a i ʻole plasma etching chambers?

A3:ʻAe. ʻAʻole hiki ke hoʻokuʻu ʻia ka alumini ceramic, kūpaʻa ka wela a me ka pale ʻana i ka corrosion-kūpono loa i nā kaiapuni kiʻekiʻe, ʻea kinoea reactive, a i ʻole plasma.

Q4: Pehea e hoʻomaʻemaʻe a mālama ʻia ai kēia mau mea?

A4:Hiki ke hoʻomaʻemaʻe ʻia me ka hoʻohana ʻana i ka wai DI, ka waiʻona, a i ʻole nā mea holoi hoʻomaʻemaʻe kūpono. ʻAʻole pono ka mālama kūikawā ma muli o ko lākou kūpaʻa kemika a me ka ʻili inert.

E pili ana iā mākou

Hoʻokumu ʻo XKH i ka hoʻomohala ʻenehana kiʻekiʻe, ka hana ʻana, a me ke kūʻai ʻana i nā aniani optical kūikawā a me nā mea aniani hou. Hāʻawi kā mākou huahana i nā uila uila, nā mea hoʻohana uila, a me ka pūʻali koa. Hāʻawi mākou i nā ʻāpana optical Sapphire, nā uhi kelepona kelepona paʻa, Ceramics, LT, Silicon Carbide SIC, Quartz, a me nā wafer kristal semiconductor. Me ka ʻike akamai a me nā mea hana ʻoki ʻoki, ʻoi aku mākou i ka hoʻoili huahana maʻamau ʻole, me ka manaʻo e lilo i alakaʻi optoelectronic material high-tech ʻoihana.