Infrared Picosecond Dual-Platform Laser Cutting Lako no ka Optical Glass/Quartz/Sapphire Processing

Pākuʻi nui

| ʻAno Laser | Picosecond infrared |

| Nui o ka Papahana | 700×1200 (mm) |

| 900×1400 (mm) | |

| Mānoanoa ʻoki ʻoki | 0.03-80 (mm) |

| ʻOki wikiwiki | 0-1000 (mm/s) |

| ʻoki ʻoki ʻoki | <0.01 (mm) |

| 'Ōlelo Aʻo: Hiki ke hoʻololi i ka nui o ka paepae. | |

Nā mea nui

1.Ultfast Laser Technology:

· Nā pulupulu pōkole pae kiʻekiʻe Picosecond (10⁻¹²s) i hui pū ʻia me ka ʻenehana hoʻokani MOPA e loaʻa i ka mana kiʻekiʻe kiʻekiʻe >10¹² W/cm².

· Komo ka lōʻihi nalu infrared (1064nm) i nā mea akaka ma o ka absorption nonlinear, e pale ana i ka wehe ʻana o ka ʻili.

· Hoʻokumu ka ʻōnaehana optical multi-focus proprietary i ʻehā mau wahi hana kūʻokoʻa i ka manawa like.

2. Pūnaehana Synchronization ʻelua-Station:

· Granite-kumu ʻelua laina laina ʻanuʻu (kūpono pololei: ± 1μm).

· Ka manawa hoʻololi o ke kahua <0.8s, hiki i nā hana like "hoʻoili-hoʻouka / wehe ʻana".

· ʻO ka mana wela kūʻokoʻa (23 ± 0.5 ° C) i kēlā me kēia kikowaena e hōʻoia i ka paʻa o ka mīkini lōʻihi.

3.Intelligent Process Control:

· ʻIkepili waiwai i hoʻohui ʻia (200+ mau ʻāpana aniani) no ka hoʻohālikelike ʻana i ka ʻokoʻa.

· Hoʻololi ikaika ka nānā ʻana i ka plasma manawa maoli (hoʻoponopono hoʻonā: 0.1mJ).

· ʻO ka pale ʻana i ka ea e hoʻemi i nā micro-cracks lihi (<3μm).

Ma kahi hihia noi maʻamau e pili ana i ka 0.5mm-mānoanoa sapphire wafer dicing, loaʻa ka ʻōnaehana i ka wikiwiki ʻoki o 300mm/s me nā ʻāpana chipping <10μm, e hōʻike ana i ka hoʻomaikaʻi maikaʻi ʻana o 5x ma mua o nā hana kuʻuna.

Nā Pono Hana Hana

1.Integrated ʻokiʻoki a me ka ʻōnaehana hoʻokaʻawale ʻelua no ka hana maʻalahi;

2.High-wikiwiki machining o paʻakikī geometries hoʻonui kaʻina hana hoʻololi pono;

3.Taper-freeʻokiʻokiʻoki me ka liʻiliʻi chipping (<50μm) a me ka mea hoʻohana-palekana lawelawe;

4.Seamless hoʻololi ma waena o nā kikoʻī huahana me ka hana intuitive;

5.Low hana koina, kiʻekiʻe yield rates, consumable-noa a me ka pollution kaʻina hana;

6.Zero generation of slag, waste water or wastewater with guaranteed surface integrity;

Hōʻike laʻana

Nā noi maʻamau

1. Mea Hoʻohana Electronics Manufacturing:

· ʻOki ʻokiʻoki pololei ʻana o ke aniani uhi uhi 3D (R-angle pololei: ± 0.01mm).

· ʻO ka ʻeli ʻana o nā puka liʻiliʻi ma nā lens wati sapphire (ka liʻiliʻi liʻiliʻi: Ø0.3mm).

· Ke hoʻopau ʻana i nā ʻāpana hoʻoili aniani aniani no nā pahu kiʻi ma lalo o ka hōʻike.

2.Optical Component Production:

· Microstructure machining no AR/VR lens arrays (nui hiʻona ≥20μm).

· ʻOki ʻokiʻoki ʻia o nā prisms quartz no nā collimators laser (ka hoʻomanawanui kihi: ±15").

· Ka hoʻopololei ʻana i nā kānana infrared (ʻoki ʻoki ʻia <0.5°).

3. Semiconductor Packaging:

· Ka hana aniani ma-via (TGV) ma ka pae wafer (kahi lākiō 1:10).

· Microchannel etching ma ke aniani substrates no microfluidic chips (Ra <0.1μm).

· Nā ʻoki hoʻokani pinepine no nā resonator quartz MEMS.

No ka hana ʻana i ka puka aniani ʻo LiDAR kaʻa, hiki i ka ʻōnaehana ke ʻoki ʻoki i ke aniani quartz 2mm-mānoanoa me ka ʻoki perpendicularity o 89.5±0.3 °, e hālāwai ana i nā koi hoʻāʻo hoʻokele automotive-grade.

Nā noi hana

Hoʻolālā ʻia no ka ʻoki pololei ʻana i nā mea brittle/paʻakikī me:

1. Ke aniani maʻamau & nā aniani aniani (BK7, fused silica);

2. ʻO nā kristal quartz a me nā substrate sapphire;

3. Ke aniani aniani a me nā kānana optical

4. Nā pani aniani

Hiki i ka ʻoki ʻoki ʻana a me ka pololei o ka hoʻoheheʻe ʻana i loko (ka liʻiliʻi Ø0.3mm)

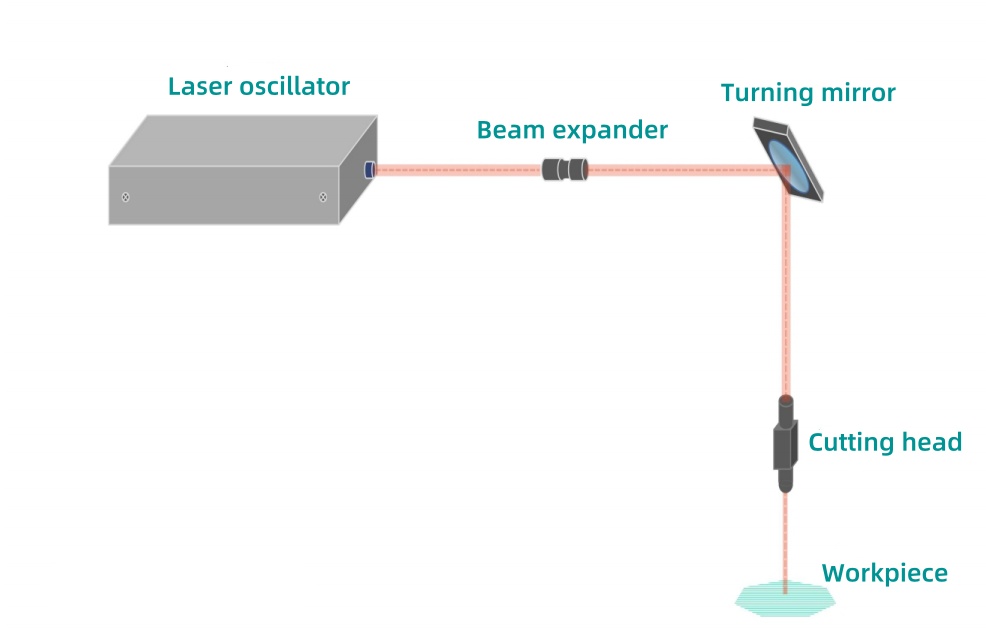

Kumu ʻOkiʻoki Laser

Hoʻopuka ka laser i nā puʻupuʻu ultrashort me ka ikehu kiʻekiʻe loa e launa pū me ka mea hana i loko o nā manawa femtosecond-to-picosecond. I ka hoʻolaha ʻana ma o ka mea, hoʻopau ka lāʻau i kona ʻano koʻikoʻi e hana i nā lua filamentation scale micron. Hoʻopuka ʻia nā māwae lua i hoʻopaʻa ʻia, e hui pū me ka ʻenehana hoʻokaʻawale e hoʻokō i ka hoʻokaʻawale pololei.

Nā Pōmaikaʻi ʻoki ʻoki Laser

1.High automation integration (hui hui 'oki/cleaving functionality) me ka haʻahaʻa mana hoʻohana a me ka maʻalahi hana;

2.Non-contact processing e hiki ai i nā mana kūikawā hikiʻole ke loaʻa ma o nāʻano maʻamau;

ʻO ka hana 3.Consumable-free e hoʻemi ana i nā kumukūʻai holo a hoʻonui i ka hoʻomau kaiapuni;

4.Superior precision me ka zero taper angle a me ka hoopau ana i ka lua workpiece poino;

Hāʻawi ʻo XKH i nā lawelawe hoʻoponopono kikoʻī no kā mākou ʻōnaehana ʻokiʻoki laser, me ka hoʻonohonoho ʻana i ka platform i hoʻonohonoho ʻia, ka hoʻomohala ʻana i ka parameter kaʻina hana kūikawā, a me nā hoʻonā kikoʻī noiʻi e hoʻokō i nā koi hana kūʻokoʻa ma nā ʻoihana like ʻole.