ʻO nā mea hana Semiconductor Laser Lift-Off e hoʻololi i ka hoʻoemi ʻana o Ingot

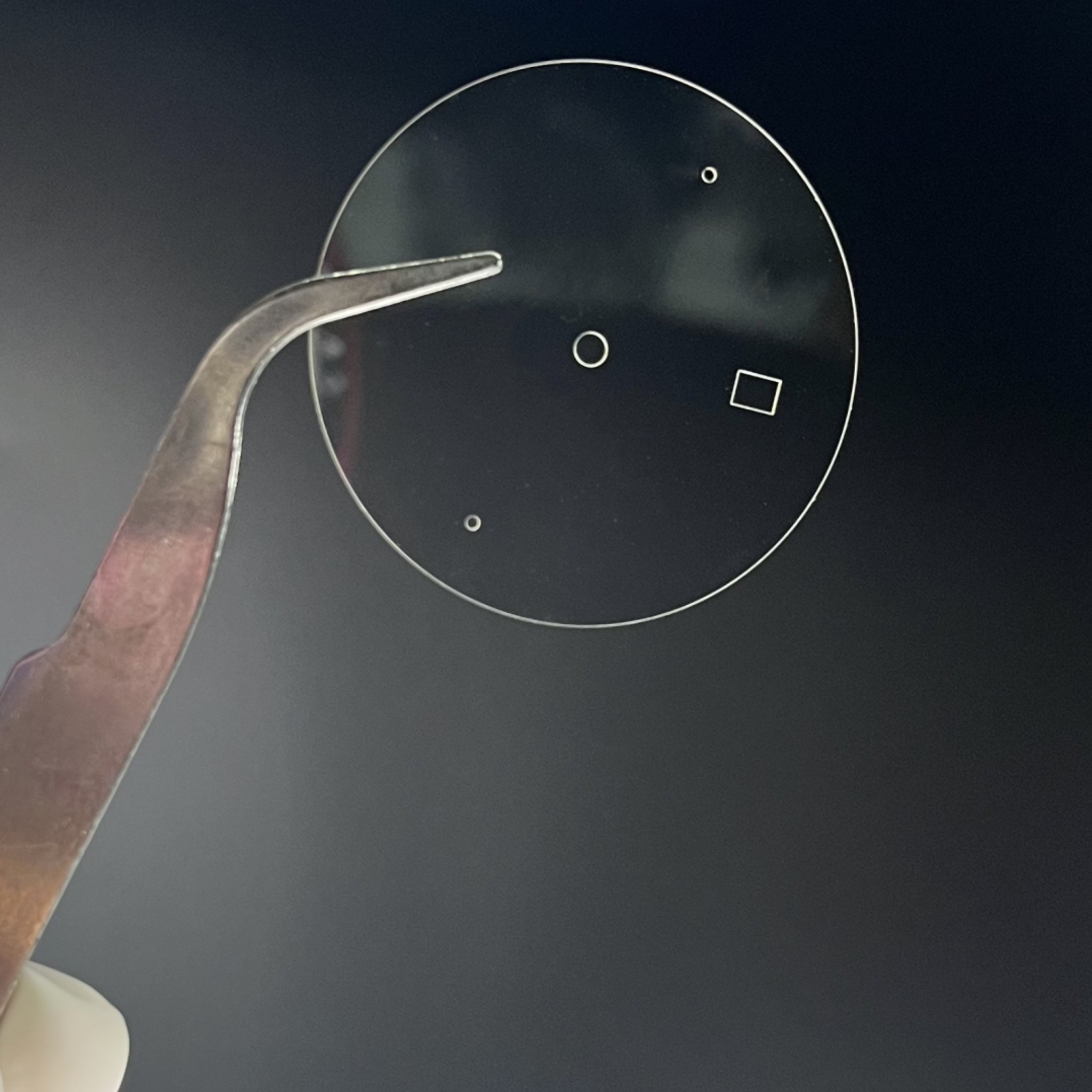

Kiʻi kikoʻī

Hoʻolauna Huahana o nā Lako Lift-Off Semiconductor Laser

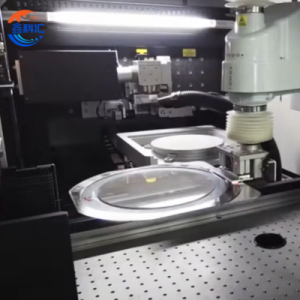

ʻO ka Semiconductor Laser Lift-Off Equipment kahi ʻenehana loea kūikawā i hana ʻia no ka hoʻoheheʻe pololei ʻana a me ka pili ʻole o nā ingots semiconductor ma o nā ʻenehana hoʻokiʻekiʻe laser-induced. He hana koʻikoʻi kēia ʻōnaehana holomua i nā kaʻina wafering semiconductor hou, ʻoi aku ka nui o ka hana ʻana i nā wafers ultra-thin no nā uila uila kiʻekiʻe, nā LED, a me nā mea RF. Ma ka ʻae ʻana i ka hoʻokaʻawale ʻana o nā ʻāpana lahilahi mai nā ingots nui a i ʻole nā mea hāʻawi mea hāʻawi, Semiconductor Laser Lift-Off Equipment e hoʻololi i ka hoʻoheheʻe ʻana i ka ingot ma o ka hoʻopau ʻana i nā ʻenekini mīkini, wili, a me nā ʻanuʻu etching kemika.

ʻO ka hoʻomaʻemaʻe kuʻuna o nā semiconductor ingots, e like me ka gallium nitride (GaN), silicon carbide (SiC), a me ka sapphire, he mea hoʻoikaika pinepine, hoʻopau ʻole, a pili i nā microcracks a i ʻole ka pōʻino o ka ʻili. ʻO ka ʻokoʻa, hāʻawi ʻo Semiconductor Laser Lift-Off Equipment i kahi ʻokoʻa hoʻopau ʻole a pololei e hōʻemi ana i ka poho waiwai a me ke koʻikoʻi o ka ʻili i ka wā e hoʻonui ai i ka huahana. Kākoʻo ia i nā ʻano like ʻole o ka crystalline a me nā mea hoʻohuihui a hiki ke hoʻohui pono ʻia i nā laina hana semiconductor mua a i ʻole midstream.

Me nā lōʻihi hawewe laser hiki ke hoʻonohonoho ʻia, nā ʻōnaehana kikoʻī adaptive, a me nā pahu wafer kūpono ʻole, ua kūpono loa kēia mea hana no ka ʻoki ʻana i ka ingot, ka hana lamella, a me ka hoʻokaʻawale kiʻiʻoniʻoni ultra-thin no nā kūkulu ʻana o nā mea kū a i ʻole ka hoʻoili ʻana o ka heteroepitaxial layer.

Ka palena o ka Lako Lift-Off Semiconductor Laser

| Loʻihi nalu | IR/SHG/THG/FHG |

|---|---|

| Pulse Laulā | Nanokekona, Picosecond, Femtosecond |

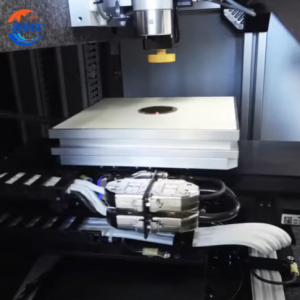

| Pūnaehana Optical | Pūnaehana optical paʻa a i ʻole ʻōnaehana Galvano-optical |

| XY Pae | 500 mm × 500 mm |

| Kaʻina Hana | 160 mm |

| Holo ka māmā | 1,000 mm/sec |

| Hiki hou | ±1 μm a emi mai paha |

| Pololei Kūlana Loa: | ±5 μm a emi mai paha |

| Nui Wafer | 2-6 iniha a i hoʻopilikino ʻia |

| Manao | Windows 10,11 a me PLC |

| Voltage Mana | AC 200 V ± 20 V, Māhele hoʻokahi, 50/60 kHz |

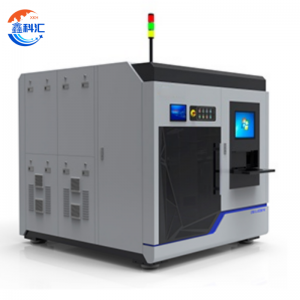

| Nā Ana Kūwaho | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Kaumaha | 1,000 kg |

Ke Kumu Hana o ka Lako Lift-Off Semiconductor Laser

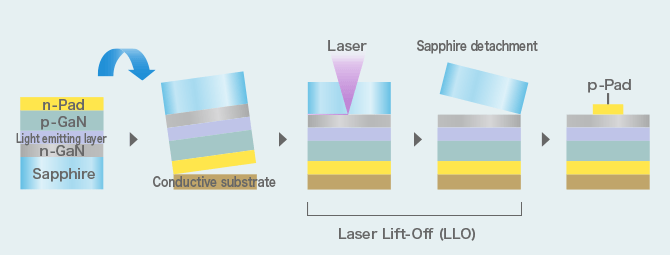

ʻO ke kumu kumu o ka Semiconductor Laser Lift-Off Equipment e hilinaʻi ana i ka decomposition photothermal koho a i ʻole ablation ma ke kikowaena ma waena o ka mea hāʻawi ingot a me ka epitaxial a i ʻole ka papa kuhikuhi. Hoʻopili ʻia kahi laser UV ikaika nui (ʻo ia hoʻi ʻo KrF ma 248 nm a i ʻole nā lasers UV solid-state ma kahi o 355 nm) e kālele ʻia ma o kahi mea hāʻawi hāʻawi a semi-transparent, kahi e hoʻopili ʻia ai ka ikehu ma kahi hohonu i koho mua ʻia.

Hoʻokumu kēia hoʻoheheʻe ʻana i ka ikehu kūloko i kahi ʻāpana kinoea kiʻekiʻe a i ʻole ka papa hoʻonui wela ma ke kikowaena, kahi e hoʻomaka ai ka hoʻomaʻemaʻe ʻana o ka wafer luna a i ʻole ka papa hana mai ke kumu ingot. Hoʻoponopono maikaʻi ʻia ke kaʻina hana ma ka hoʻoponopono ʻana i nā ʻāpana e like me ka laula pulse, fluence laser, scanning speed, a me ka hohonu o ka z-axis. ʻO ka hopena he ʻāpana lahilahi loa—pinepine ma ka laulā 10 a 50 µm—i hoʻokaʻawale maʻemaʻe ʻia mai ka ingot makua me ka ʻole o ka abrasion mechanical.

ʻO kēia ʻano o ka hoʻokiʻekiʻe ʻana i ka laser no ka hoʻoheheʻe ʻana i ka ingot e pale aku i ka poho kerf a me ka pōʻino o ka ʻili e pili ana i ka ʻili uea daimana a i ʻole ka lapping mechanical. Mālama pū ʻo ia i ka pono aniani a hōʻemi i nā koi polishing downstream, e hana ana i ka Semiconductor Laser Lift-Off Equipment i mea hana hoʻololi pāʻani no ka hana wafer hanauna hou.

Noi o ka Semiconductor Laser Lift-Off Lako

Loaʻa ka Semiconductor Laser Lift-Off Equipment i ka hoʻohana nui ʻana i ka hoʻoheheʻe ʻana i ka ingot ma waena o nā ʻano mea holomua a me nā ʻano mea hana, me:

-

ʻO GaN a me GaAs Ingot Thinning no nā mea mana

Hiki i ka hana ʻana i ka wafer lahilahi no nā transistors mana haʻahaʻa haʻahaʻa a me nā diodes.

-

ʻO SiC Substrate Reclamation a me Lamella Separation

E ʻae i ka hoʻokiʻekiʻe ʻana i ka nui o ka wafer mai nā substrate SiC nui no ka hoʻolālā ʻana o nā mea hana a me ka hoʻohana hou ʻana i ka wafer.

-

LED Wafer Slicing

Hoʻomaʻamaʻa i ka hoʻokuʻu ʻana i nā papa GaN mai nā ingots sapphire mānoanoa e hana i nā substrate LED ultra-thin.

-

RF a me ka Microwave Mea Hana Hana

Kākoʻo i nā hale transistor (HEMT) ultra-thin high-electron-mobility transistor e pono ai ma 5G a me nā ʻōnaehana radar.

-

Epitaxial Layer Transfer

Hoʻokaʻawale pololei i nā papa epitaxial mai nā ingots crystalline no ka hoʻohana hou ʻana a i ʻole ka hoʻohui ʻana i nā heterostructure.

-

Nā Kiʻiʻoniʻoni ʻoniʻoni ʻoniʻoni a me nā Photovoltaics

Hoʻohana ʻia no ka hoʻokaʻawale ʻana i nā ʻāpana hoʻoheheʻe lahilahi no nā cell solar maʻalahi a kiʻekiʻe.

Ma kēlā me kēia o kēia mau kikowaena, hāʻawi ka Semiconductor Laser Lift-Off Equipment i ka mana like ʻole ma luna o ka like ʻole o ka mānoanoa, ka maikaʻi o ka ʻili, a me ka pono o ka papa.

ʻO nā mea maikaʻi o ka hoʻomaʻamaʻa ʻana i ka Ingot Thinning

-

Nalo waiwai Zero-Kerf

Ke hoʻohālikelike ʻia i nā ʻano hana ʻoki wafer kuʻuna, ʻo ke kaʻina laser ka hopena ma kahi o 100% ka hoʻohana ʻana i nā mea.

-

ʻO ke koʻikoʻi liʻiliʻi a me ka warping

Hoʻopau ka hoʻokiʻekiʻe pili ʻole i ka haʻalulu mechanical, hōʻemi i ke kakaka wafer a me ka hoʻokumu ʻana o ka microcrack.

-

Mālama maikaʻi o ka ʻili

ʻAʻole koi ʻia ka lapping post-thinning a polishing i nā hihia he nui, no ka mea, mālama ka laser lift-off i ka pono o luna.

-

Mākaukau ʻo High Throughput a me Automation

Hiki iā ia ke hoʻoponopono i nā haneli o nā substrate i kēlā me kēia neʻe me ka hoʻouka / hoʻoiho ʻana.

-

Hiki ke hoʻololi i nā mea he nui

He kūpono me GaN, SiC, sapphire, GaA, a me nā mea III-V e puka mai ana.

-

Palekana Kaiapuni

Hoʻemi i ka hoʻohana ʻana i nā mea abrasives a me nā kemika koʻikoʻi maʻamau i nā kaʻina hana slurry-based thinning.

-

Hoʻohana hou i ka substrate

Hiki ke hana hou ʻia nā mea hāʻawi kālā no nā pōʻai hoʻokiʻekiʻe he nui, e hōʻemi nui ana i nā kumu kūʻai.

Nā nīnau i nīnau pinepine ʻia (FAQ) o Semiconductor Laser Lift-Off Equipment

-

Q1: He aha ka mānoanoa e hiki ai i ka Semiconductor Laser Lift-Off Equipment ke hoʻokō no nā ʻāpana wafer?

A1:ʻO ka mānoanoa ʻāpana maʻamau mai 10 µm a i 100 µm ma muli o ka mea a me ka hoʻonohonoho.Q2: Hiki ke hoʻohana ʻia kēia mea hana i nā ingots lahilahi i hana ʻia me nā mea opaque e like me SiC?

A2:ʻAe. Ma ka hoʻopaʻa ʻana i ka lōʻihi hawewe laser a me ka hoʻomaikaʻi ʻana i ka ʻenekinia interface (e laʻa, nā mea hoʻolaʻa mōhai), hiki ke hana ʻia nā mea opaque.Q3: Pehea e hoʻopili ʻia ai ka substrate hāʻawi ma mua o ka hāpai ʻana i ka laser?

A3:Hoʻohana ka ʻōnaehana i nā modula hoʻohālikelike sub-micron vision-based me nā manaʻo mai nā hōʻailona fiducial a me ka nānā ʻana i ka nānā ʻana i ka ʻili.Q4: He aha ka manawa pōkole i manaʻo ʻia no hoʻokahi hana hoʻokiʻekiʻe laser?

A4:Ma muli o ka nui o ka wafer a me ka mānoanoa, mau kaʻina maʻamau mai 2 a 10 mau minuke.Q5: Pono ke kaʻina hana i kahi lumi maʻemaʻe?

A5:ʻOiai ʻaʻole koi ʻia, ʻōlelo ʻia ka hoʻohui ʻana o ka lumi maʻemaʻe e mālama i ka hoʻomaʻemaʻe substrate a me ka hoʻohua ʻana o nā mea hana i ka wā o nā hana kiʻekiʻe.

E pili ana iā mākou

Hoʻokumu ʻo XKH i ka hoʻomohala ʻenehana kiʻekiʻe, ka hana ʻana, a me ke kūʻai ʻana i nā aniani optical kūikawā a me nā mea aniani hou. Hāʻawi kā mākou huahana i nā uila uila, nā mea hoʻohana uila, a me ka pūʻali koa. Hāʻawi mākou i nā ʻāpana optical Sapphire, nā uhi kelepona kelepona paʻa, Ceramics, LT, Silicon Carbide SIC, Quartz, a me nā wafer kristal semiconductor. Me ka ʻike akamai a me nā mea hana ʻoki ʻoki, ʻoi aku mākou i ka hoʻoili huahana maʻamau ʻole, me ka manaʻo e lilo i alakaʻi optoelectronic material high-tech ʻoihana.