ʻO ka pā kīʻaha SiC nā kīʻaha hoʻoheheʻe ceramic i hoʻopilikino ʻia

Nā hiʻohiʻona waiwai:

1.High paakiki: ka Mohs paakiki o ka silicon carbide he 9.2-9.5, ka lua wale no i daimana, me ka ikaika aahu pale.

2. Kiʻekiʻe thermal conductivity: ka thermal conductivity o ka silicon carbide kiʻekiʻe e like me 120-200 W / m·K, hiki ke hoʻopau koke i ka wela a kūpono no ke kaiapuni wela kiʻekiʻe.

3. He haʻahaʻa ka hoʻonui ʻana o ka wela haʻahaʻa: ʻoi aku ka liʻiliʻi o ka nui o ka hoʻonui ʻana i ka wela silicon carbide (4.0-4.5 × 10⁻⁶/K), hiki ke mālama i ke kūpaʻa dimensional i ke kiʻekiʻe wela.

4. Paʻa kemika: ʻakika carbide silicon a me ka pale ʻana i ka corrosion alkali, kūpono no ka hoʻohana ʻana i ke kaiapuni corrosive.

5. Ka ikaika mechanical kiʻekiʻe: silicon carbide i kiʻekiʻe kulou ikaika a me ka compressive ikaika, a hiki ke ku i ka mechanical stress nui.

Nā hiʻohiʻona:

1. I loko o kaʻoihana semiconductor, pono e kauʻia nā wafers lahilahi loa ma luna o ke kīʻaha hoʻoheheʻeʻia, hoʻohanaʻia ka'ōmole'ōmole no ka hoʻoponoponoʻana i nā wafers, a ke hanaʻia ke kaʻina hana o ka waxing, thinning, waxing, hoʻomaʻemaʻe a me kaʻokiʻana i nā wafers.

2.Silicon carbide sucker he maikai thermal conductivity, hiki pono ke hoopokole i ka waxing a me ka waxing manawa, hoonui i ka hana pono.

3.Silicon carbide vacuum sucker no hoi maikai ka waika a me ka alkali corrosion kū'ē.

4. Hoʻohālikelike me ka papa lawe corundum maʻamau, e hoʻopōkole i ka hoʻoukaʻana a me ka weheʻana i ka hoʻomehana a me ka manawa hoʻomaha, e hoʻonui i ka pono o ka hana; I ka manawa like, hiki iā ia ke hōʻemi i ka ʻaʻahu ma waena o nā papa luna a me lalo, mālama i ka pololei o ka mokulele, a hoʻonui i ke ola lawelawe ma kahi o 40%.

5. He mea liʻiliʻi ka nui o nā mea, ke kaumaha māmā. ʻOi aku ka maʻalahi o nā mea hana e lawe i nā pallets, e hōʻemi ana i ka hopena o ka pōʻino collision i hoʻokumu ʻia e nā pilikia o ka halihali ma kahi o 20%.

6.Size: ke anawaena kiʻekiʻe 640mm; Paha: 3um a emi mai paha

Kahua noi:

1. Hana semiconductor

●Ka hana wafer:

No ka wafer fixation i photolithography, etching, thin film deposition a me nā kaʻina hana ʻē aʻe, e hōʻoia ana i ka pololei kiʻekiʻe a me ke kaʻina hana. ʻO kona kiʻekiʻe kiʻekiʻe a me ka pale ʻana i ka corrosion he kūpono ia no nā wahi hana semiconductor koʻikoʻi.

●Epitaxial ulu:

Ma SiC a i ʻole GaN epitaxial ulu, ma ke ʻano he mea lawe i ka wela a hoʻoponopono i nā wafers, e hōʻoiaʻiʻo ana i ka kūlike o ka mahana a me ka maikaʻi aniani i nā wela kiʻekiʻe, e hoʻomaikaʻi ana i ka hana ʻana o ka mea hana.

2. Nā lako paʻi kiʻi

●LED Manufacturing:

Hoʻohana ʻia e hoʻoponopono i ka sapphire a i ʻole SiC substrate, a ma ke ʻano he mea lawe wela i ke kaʻina MOCVD, e hōʻoia i ka kūlike o ka ulu epitaxial, hoʻomaikaʻi i ka pono a me ka maikaʻi o LED.

● Laser diode:

Ma ke ʻano he kiʻekiʻe kiʻekiʻe, hoʻoponopono a hoʻomehana i ka substrate e hōʻoia i ka paʻa ʻana o ka mahana, hoʻomaikaʻi i ka mana puka a me ka hilinaʻi o ka diode laser.

3. Mīkini pololei

●Ka hana ʻana o nā ʻāpana Optical:

Hoʻohana ʻia ia no ka hoʻoponopono ʻana i nā mea kikoʻī e like me nā lens optical a me nā kānana e hōʻoia i ka pololei kiʻekiʻe a me ka haʻahaʻa haʻahaʻa i ka wā o ka hana ʻana, a kūpono no ka mīkini kiʻekiʻe.

●Ka hana seramika:

Ma ke ʻano he paʻa paʻa kiʻekiʻe, kūpono ia no ka mīkini pololei o nā mea seramika e hōʻoia i ka pololei o ka mīkini a me ka paʻa ʻana ma lalo o ke kiʻekiʻe kiʻekiʻe a me ka corrosive environment.

4. Nā hoʻokolohua ʻepekema

● hoʻokolohua wela kiʻekiʻe:

Ma ke ʻano he laʻana hoʻoponopono i nā kaiapuni kiʻekiʻe, kākoʻo ia i nā hoʻokolohua wela loa ma luna o 1600°C e hōʻoia i ka kūlike o ka mahana a me ka paʻa o ka laʻana.

● ho'āʻo māhu:

E like me ka laʻana hoʻoponopono a me ka hoʻomehana ʻana i loko o ka ʻenekema, e hōʻoia i ka pololei a me ka repeatability o ka hoʻokolohua, kūpono no ka uhi ʻana a me ka mālama wela.

Nā kikoʻī kikoʻī:

| (Waiwai waiwai) | (Ui) | (ssic) | |

| (Maʻiʻo SiC) |

| (Wt)% | >99 |

| (Ka nui o ka palaoa maʻamau) |

| micron | 4-10 |

| (Density) |

| kg/dm3 | >3.14 |

| (Ka ʻike ʻia o ka porosity) |

| Vo1% | <0.5 |

| (Vickers paakiki) | HV 0.5 | GPa | 28 |

| *( Ka ikaika wiliwili) | 20ºC | MPa | 450 |

| (Ka ikaika compressive) | 20ºC | MPa | 3900 |

| (Elastic Modulus) | 20ºC | GPa | 420 |

| (Oolea ha'iha'i) |

| MPa/m'% | 3.5 |

| (Hana wela) | 20°ºC | W/(m*K) | 160 |

| (Ke kū'ē) | 20°ºC | ʻŌm.cm | 106-108 |

|

| a(RT**...80ºC) | K-1*10-6 | 4.3 |

|

|

| oºC | 1700 |

Me nā makahiki o ka hōʻiliʻili ʻenehana a me ka ʻike ʻoihana, hiki iā XKH ke hoʻoponopono i nā ʻāpana kī e like me ka nui, ke ʻano hoʻomehana a me ka hoʻolālā adsorption vacuum o ka chuck e like me nā pono kikoʻī o ka mea kūʻai aku, e hōʻoiaʻiʻo i ka hoʻololi pono ʻana o ka huahana i ke kaʻina hana o ka mea kūʻai. Ua lilo ʻo SiC silicon carbide ceramic chucks i mea nui i ka hana wafer, ka ulu ʻana o ka epitaxial a me nā kaʻina hana ʻē aʻe ma muli o kā lākou conductivity thermal maikaʻi loa, ke kūpaʻa wela kiʻekiʻe a me ke kūpaʻa kemika. ʻOi aku ka nui o ka hana ʻana i nā mea semiconductor ʻekolu o nā hanauna e like me SiC a me GaN, ke hoʻomau nei ke koi ʻana no nā silicon carbide ceramic chucks. I ka wā e hiki mai ana, me ka hoʻomohala wikiwiki ʻana o 5G, nā kaʻa uila, naʻauao artificial a me nā ʻenehana ʻē aʻe, e ʻoi aku ka laulā o ka noi ʻana o ka silicon carbide ceramic chucks i ka ʻoihana semiconductor.

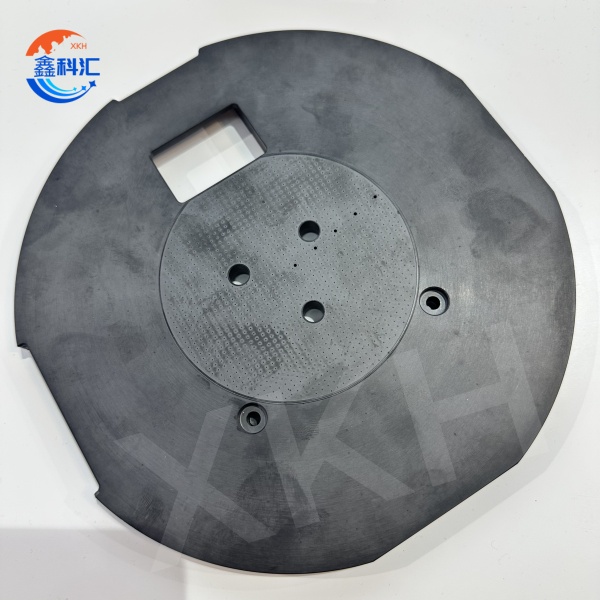

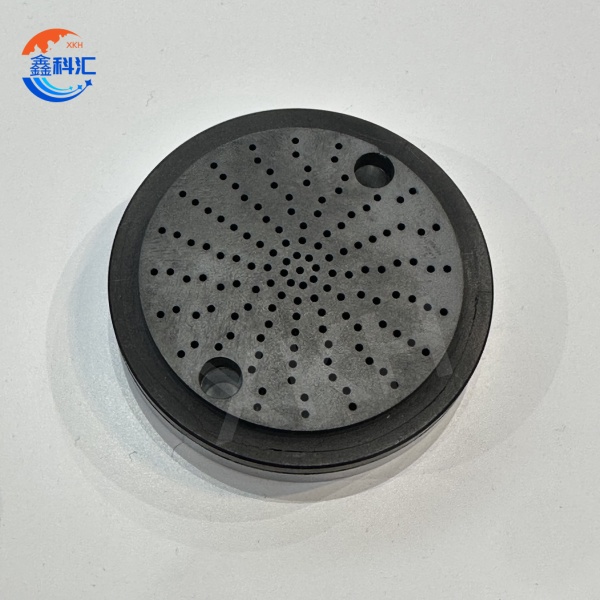

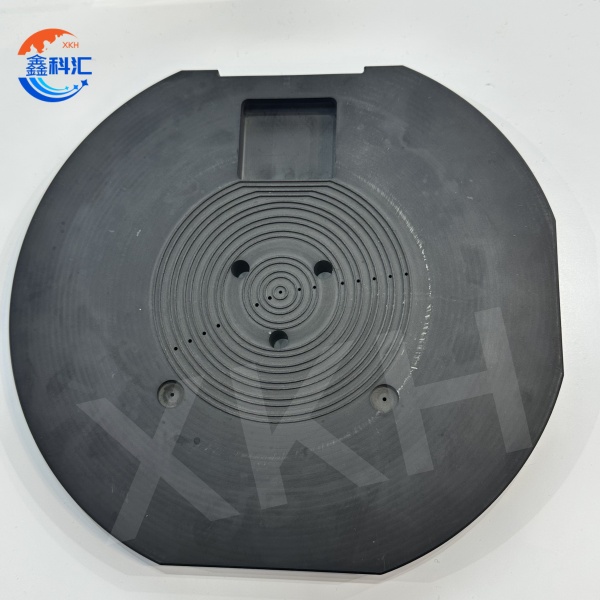

Kiʻi kikoʻī