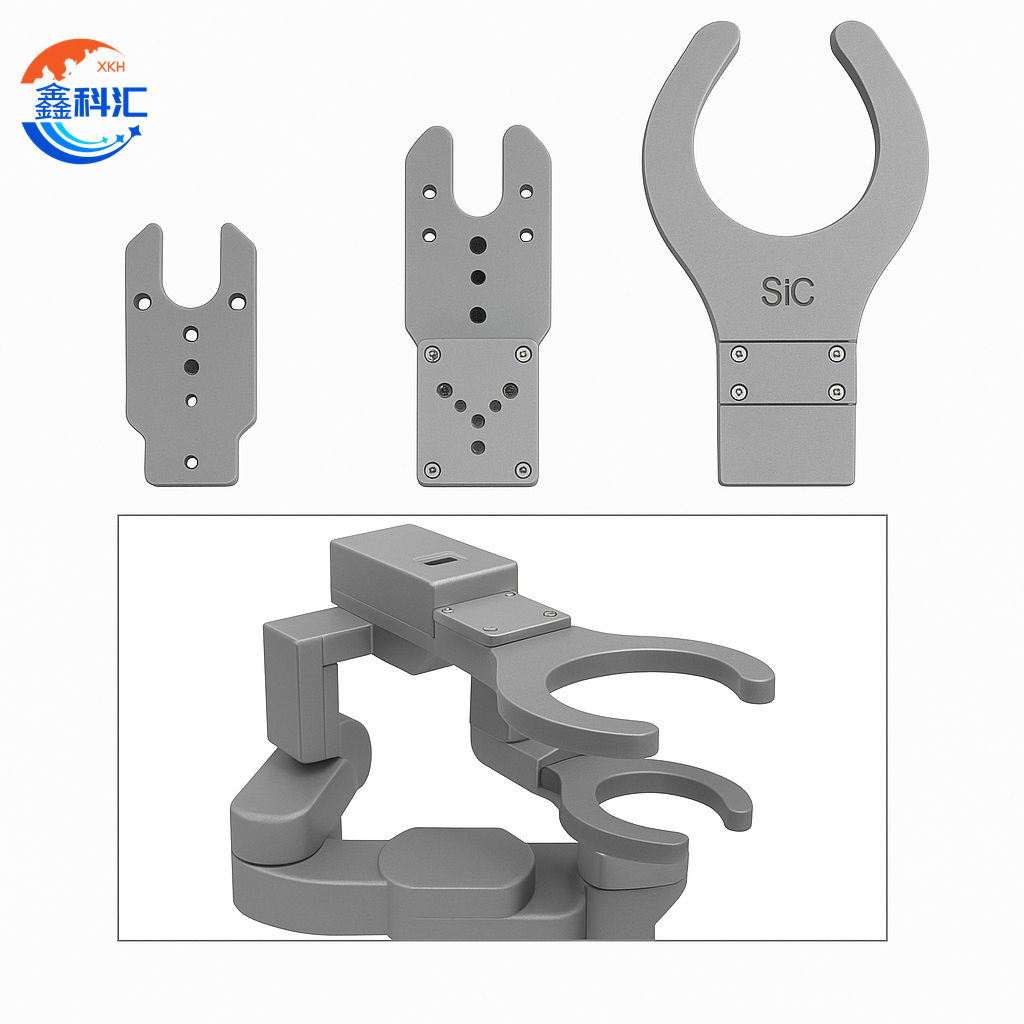

Hāʻawi lima lima ʻo SiC no ka lawe ʻana i ka wafer

SiC ceramic hope effector Abstract

He mea koʻikoʻi ka SiC (Silicon Carbide) ceramic end-effector i nā ʻōnaehana hoʻokele wafer kiʻekiʻe i hoʻohana ʻia i ka hana semiconductor a me nā wahi microfabrication holomua. Hana ʻia e hoʻokō i nā koi koi o nā kaiapuni ultra-maʻemaʻe, wela kiʻekiʻe, a paʻa loa, e hōʻoia kēia hopena hopena kūikawā i ka lawe ʻana i nā wafers i ka wā hana nui e like me ka lithography, etching, a me deposition.

ʻO ka hoʻohana ʻana i nā waiwai waiwai o ka silicon carbide-e like me ke kiʻekiʻe o ka wela, ka paʻakikī loa, ka inertness kemika maikaʻi loa, a me ka hoʻonui ʻana i ka wela liʻiliʻi - hāʻawi ka SiC ceramic end-effector i ka ʻoʻoleʻa mechanical like ʻole a me ke kūpaʻa ʻana ma lalo o ke kaʻa uila wikiwiki a i loko o nā keʻena hana corrosive. ʻO kona ʻano haʻahaʻa haʻahaʻa haʻahaʻa a me nā hiʻohiʻona kūpaʻa plasma e kūpono loa ia no ka lumi maʻemaʻe a me nā noi hoʻoili ʻana i ka vacuum, kahi e mālama ai i ka pono o ka ʻili wafer a me ka hōʻemi ʻana i ka palaka.

ʻO ka hoʻohana hopena hopena hopena SiC

1. Hana ʻana i ka Wafer Semiconductor

Hoʻohana nui ʻia nā hopena hopena seramika SiC i ka ʻoihana semiconductor no ka mālama ʻana i nā wafer silika i ka wā hana automated. Hoʻokomo pinepine ʻia kēia mau hopena hopena ma nā lima robotic a i ʻole nā pūnaewele hoʻololi ʻana a hoʻolālā ʻia e hoʻokipa i nā wafers o nā ʻano nui like ʻole me 200mm a me 300mm. Pono lākou i nā kaʻina hana e like me ka Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), etching, a me ka hoʻopuehu ʻana - kahi maʻamau ka wela kiʻekiʻe, nā kūlana ʻawaʻawa, a me nā kinoea corrosive. ʻO ke kūʻokoʻa wela o SiC a me ka paʻa kemika e lilo ia i mea kūpono no ke kū ʻana i ia ʻano ʻino me ka ʻole o ka hōʻino.

2. ʻO ka lumi hoʻomaʻemaʻe a me ka hoʻopili ʻana i ka ʻūhā

I loko o ka lumi hoʻomaʻemaʻe a me ka hoʻonohonoho ʻana, kahi e hoʻemi ʻia ai ka hoʻohaumia ʻana i ka ʻāpana, hāʻawi nā ceramics SiC i nā pono nui. ʻO ka ʻeleʻele paʻakikī o ka ʻili e kūʻē i ka hana ʻana i nā ʻāpana, kōkua i ka mālama pono ʻana i ka wafer i ka wā o ka lawe ʻana. ʻO kēia ka mea i kūpono loa i nā hopena hopena SiC no nā kaʻina hana koʻikoʻi e like me Extreme Ultraviolet Lithography (EUV) a me Atomic Layer Deposition (ALD), kahi mea koʻikoʻi ka maʻemaʻe. Eia kekahi, ʻo ka haʻahaʻa haʻahaʻa haʻahaʻa o SiC a me ke kūpaʻa plasma kiʻekiʻe e hōʻoia i ka hana hilinaʻi i loko o nā keʻena vacuum, e hoʻolōʻihi i ke ola o nā mea hana a me ka hōʻemi ʻana i ke alapine mālama.

3. Kiekie-Precision Positioning System

He mea koʻikoʻi ka pololei a me ka paʻa i nā ʻōnaehana lawelawe wafer holomua, ʻoi aku hoʻi i ka metrology, inspection, a me nā mea hana alignment. He haʻahaʻa haʻahaʻa haʻahaʻa loa nā ceramics SiC o ka hoʻonui wela a me ka ʻoʻoleʻa kiʻekiʻe, e ʻae ai i ka hopena hopena e hoʻomau i ka pololei o kona kūkulu ʻana ma lalo o ke kaʻa uila a i ʻole ka ukana mechanical. Mālama kēia i ka hoʻopaʻa pololei ʻana o nā wafers i ka wā o ka lawe ʻana, e hōʻemi ana i ka pilikia o nā micro-scratches, misalignment, a i ʻole ke ana ʻana i nā hewa - nā kumu i koʻikoʻi nui i nā nodes kaʻina sub-5nm.

ʻO ka SiC ceramic end effector Properties

1. Kiekie Mechanical ikaika a paakiki

Loaʻa i nā ceramics SiC ka ikaika mechanical, me ka ikaika hoʻololi pinepine ma mua o 400 MPa a me nā waiwai paʻakikī Vickers ma luna o 2000 HV. ʻO kēia ke kūpaʻa loa iā lākou i ke koʻikoʻi mechanical, ka hopena, a me ka lole, ʻoiai ma hope o ka hoʻohana lōʻihi ʻana. ʻO ka rigidity kiʻekiʻe o SiC e hōʻemi i ka deflection i ka wā o ka hoʻololi ʻana i ka wafer kiʻekiʻe, e hōʻoiaʻiʻo ana i ka pololei a me ka hoʻihoʻi hou ʻana.

2. Paʻa wela wela maikaʻi loa

ʻO kekahi o nā mea waiwai nui o nā seramika SiC ʻo ko lākou hiki ke kū i nā wela kiʻekiʻe loa-pinepine a hiki i 1600 ° C i nā lewa inert-me ka nalowale ʻole o ka pono mechanical. ʻO kā lākou helu haʻahaʻa o ka hoʻonui wela (~ 4.0 x 10⁻⁶ /K) e hōʻoia i ka paʻa o ka dimensional ma lalo o ke kaʻa uila, e hoʻolilo iā lākou i mea kūpono no nā noi e like me CVD, PVD, a me ka annealing kiʻekiʻe.

Q&A ka mea hoʻopau seramika SiC

Nīnau: He aha nā mea i hoʻohana ʻia i ka hopena hopena wafer?

A:Hana ʻia nā hopena hopena Wafer mai nā mea e hāʻawi ana i ka ikaika kiʻekiʻe, ke kūpaʻa wela, a me ka hana haʻahaʻa haʻahaʻa. Ma waena o kēia mau mea, ʻo Silicon Carbide (SiC) ceramic kekahi o nā mea kiʻekiʻe loa a makemake ʻia. ʻO nā seramika SiC he paʻakikī loa, paʻa ka wela, kemika inert, a kūpaʻa i ka ʻaʻahu ʻana, no laila kūpono lākou no ka lawelawe ʻana i nā wafers silika maʻemaʻe a me nā kaiapuni. Ke hoʻohālikelike ʻia me ka quartz a i ʻole nā metala i uhi ʻia, hāʻawi ʻo SiC i ka paʻa o ka dimensional kiʻekiʻe ma lalo o nā wela kiʻekiʻe a ʻaʻole hoʻokahe i nā ʻāpana, e kōkua i ka pale ʻana i ka pala.