ʻO SiC Ceramic Tray no ka Wafer Carrier me ke kūpaʻa wela kiʻekiʻe

ʻO ka Paʻa Silikona Carbide Ceramic (SiC Tray)

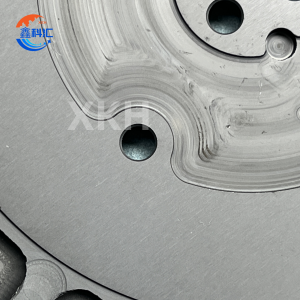

ʻO kahi ʻāpana seramika hana kiʻekiʻe e pili ana i ka mea silicon carbide (SiC), i hana ʻia no nā noi ʻoihana holomua e like me ka hana semiconductor a me ka hana LED. ʻO kāna mau hana koʻikoʻi, ʻo ia ka lawelawe ʻana ma ke ʻano he wafer carrier, etching process platform, a i ʻole ke kākoʻo kaʻina hana kiʻekiʻe, ka hoʻohana ʻana i ka conductivity thermal kūikawā, ke kūpaʻa wela kiʻekiʻe, a me ke kūpaʻa kemika e hōʻoia i ka like ʻana o ke kaʻina hana a me ka hua huahana.

Nā hiʻohiʻona nui

1. Hana wela

- ʻO ka hana wela kiʻekiʻe: 140–300 W/m·K, ʻoi loa ma mua o ka graphite kuʻuna (85 W/m·K), hiki ke hoʻopau koke i ka wela a hōʻemi i ke kaumaha wela.

- ʻO ka Coefficient Hoʻonui Thermal Haʻahaʻa: 4.0 × 10⁻⁶/℃ (25–1000 ℃), pili kokoke i ke silika (2.6×10⁻⁶/℃), e hōʻemi ana i nā pilikia deformation thermal.

2. ʻAno Mechanical

- Ka ikaika kiʻekiʻe: ʻO ka ikaika flexural ≥320 MPa (20 ℃), kūpaʻa i ka paʻi a me ka hopena.

- Paʻa Kiʻekiʻe: Mohs hardness 9.5, ka lua wale nō i ke daimana, e hāʻawi ana i ke kūpaʻa ʻoi aku ka maikaʻi.

3. Paʻa Kemika

- Kū'ē Kū'ē: Kū'ē i nā ʻakika ikaika (e laʻa, HF, H₂SO₄), kūpono no nā kaʻina hana etching.

- ʻAʻole Magnetic: ʻAʻole hiki ke hoʻopaʻa ʻia i loko o ka emu/g, e pale ana i ka hoʻopili ʻana i nā mea hana pololei.

4. Hoʻomanawanui Kaiapuni Nui

- ʻO ka lōʻihi o ka wela: ʻO ka mahana hana lōʻihi a hiki i 1600-1900 ℃; ʻO ke kūpaʻa pōkole a hiki i ka 2200 ℃ (kahi oxygen-free environment).

- ʻO ke kūpaʻa haʻalulu wela: ʻaʻa i nā loli wela (ΔT>1000 ℃) me ka ʻole o ka haki ʻana.

Nā noi

| Kahua noi | Nā Kūlana Kūikawā | Waiwai ʻenehana |

| Hana ʻia Semiconductor | Wafer etching (ICP), thin-film deposition (MOCVD), CMP polishing | ʻO ka conductivity thermal kiʻekiʻe e hōʻoiaʻiʻo i nā māla wela like ʻole; liʻiliʻi ka hoʻonui wela haʻahaʻa. |

| Hana ʻia ʻo LED | Epitaxial ulu (e laʻa, GaN), wafer dicing, paʻi | Kāohi i nā ʻano kīnā he nui, hoʻonui i ka pono kukui LED a me ke ola. |

| ʻOihana Photovoltaic | ʻO nā kapuahi hoʻoheheʻe wafer silikoni, nā mea kākoʻo PECVD | ʻO ke kūpaʻa kiʻekiʻe a me ka haʻalulu wela e hoʻonui i ke ola o nā mea hana. |

| ʻO ka Laser & Optik | ʻO nā substrate hoʻoluʻu laser mana kiʻekiʻe, kākoʻo ʻōnaehana optical | Hiki ke hoʻokuʻu ʻia ka wela kiʻekiʻe, hoʻopaʻa i nā ʻāpana optical. |

| Mea Hana Analytical | Nā mea hoʻohālike TGA/DSC | ʻO ka hiki haʻahaʻa wela a me ka pane wela wikiwiki e hoʻomaikaʻi i ke ana pololei. |

Nā mea pono o nā huahana

- ʻOi aku ka maikaʻi o ka hoʻokō ʻana i ka wela, ka ikaika, a me ka pale ʻana i ka corrosion ma mua o ka alumina a me ka silicon nitride ceramics, e hālāwai ana i nā koi hana koʻikoʻi.

- Māmā Māmā: Density o 3.1–3.2 g/cm³ (40% o ke kila), e hōʻemi ana i ka ukana inertial a hoʻonui i ka pololei o ka neʻe.

- Ka lōʻihi a me ka hilinaʻi: ʻOi aku ke ola o ka lawelawe ma mua o 5 mau makahiki ma 1600 ℃, e hōʻemi ana i ka manawa haʻahaʻa a hoʻohaʻahaʻa i nā kumukūʻai hana e 30%.

- Hoʻopilikino: Kākoʻo i nā geometries paʻakikī (e laʻa, nā kīʻaha porous suction, multi-layer trays) me ka hala palaha <15 μm no nā noi pololei.

ʻIkepili ʻenehana

| Māhele Parameter | Mea hōʻike |

| Na Waiwai Kino | |

| ʻO ka mānoanoa | ≥3.10 g/cm³ |

| ʻO ka ikaika hoʻololi (20 ℃) | 320–410 MPa |

| ʻO ka hoʻokō wela (20 ℃) | 140–300 W/(m·K) |

| Koefficient Hoʻonui Thermal (25–1000 ℃) | 4.0×10⁻⁶/℃ |

| Nā waiwai kemika | |

| Palekana ʻAka (HF/H₂SO₄) | ʻAʻohe ʻino ma hope o 24h immersion |

| Mīkini pololei | |

| Palahalaha | ≤15 μm (300×300 mm) |

| ʻO ʻAla ʻili (Ra) | ≤0.4 μm |

Nā lawelawe a XKH

Hāʻawi ʻo XKH i nā hoʻonā ʻenehana holoʻokoʻa e pili ana i ka hoʻomohala maʻamau, ka mīkini kikoʻī, a me ka mana o ka maikaʻi. No ka hoʻomohala maʻamau, hāʻawi ia i ka hoʻomaʻemaʻe kiʻekiʻe (> 99.999%) a me ka porous (30-50% porosity) nā hoʻonā waiwai, i hui pū ʻia me ka hoʻohālike 3D a me ka simulation e hoʻopaʻa i nā geometries paʻakikī no nā noi e like me semiconductors a me ka aerospace. ʻO ka mīkini pololei e hahai ana i ke kaʻina hana maʻalahi: ka hana pauka → isostatic/dry pressing → 2200°C sintering → CNC/diamond grinding → inspection, e hōʻoia ana i ka nanometer-level polishing a me ka ±0.01 mm dimensional tolerance. Loaʻa ka mana o ka maikaʻi i ka hoʻāʻo piha (XRD haku mele, SEM microstructure, 3-point bending) a me ke kākoʻo ʻenehana (hoʻoponopono kaʻina hana, 24/7 kūkākūkā, 48-hola hāʻawi hāʻawi), hāʻawi i nā mea hilinaʻi, hana kiʻekiʻe no nā pono ʻoihana holomua.

Nā nīnau i nīnau pinepine ʻia (FAQ)

1. Nīnau: He aha nā ʻoihana e hoʻohana ai i nā pā seramika silicon carbide?

A: Hoʻohana nui ʻia i ka hana semiconductor (wafer handling), solar energy (ka hana PECVD), nā lāʻau lapaʻau (MRI component), a me aerospace (mau ʻāpana wela kiʻekiʻe) ma muli o ko lākou kūpaʻa wela a me ka paʻa kemika.

2. Nīnau: Pehea e ʻoi aku ka maikaʻi o ka silicon carbide i nā pā quartz/aniani?

A: ʻOi aku ka ikaika o ka haʻalulu wela (a hiki i 1800°C vs. quartz's 1100°C), ʻeleʻele magnetic, a ʻoi aku ka lōʻihi o ke ola (5+ makahiki vs. quartz's 6-12 mahina).

3. Nīnau: Hiki i nā pā karbida silika ke mālama i nā kaiapuni ʻakika?

A: ʻAe. Kū'ē iā HF, H2SO4, a me NaOH me <0.01mm corrosion/makahiki, e hoʻolilo iā lākou i mea kūpono no ka etching kemika a me ka hoʻomaʻemaʻe wafer.

4. Nīnau: Ua kūpono anei nā pā kilika carbide me ka automation?

A: ʻAe. Hoʻolālā ʻia no ka ʻohi ʻana a me ka hoʻokele robotic, me ka palahalaha o ka ʻili <0.01mm e pale ai i ka hoʻohaumia ʻana i nā ʻāpana i loko o nā mea hana automated.

5. Q: He aha ke kumukūʻai hoʻohālikelike me nā mea kuʻuna?

A: ʻO ke kumu kūʻai kiʻekiʻe aʻe (3-5x quartz) akā 30-50% haʻahaʻa TCO ma muli o ke ola lōʻihi, hoʻemi ʻia ka manawa haʻahaʻa, a me ka mālama ʻana i ka ikehu mai ka conductivity thermal kiʻekiʻe.