ʻO ka pāpaʻi ʻeleʻele Silicon Carbide – Paʻa mau, nā pā hana kiʻekiʻe no ka hoʻohana ʻana i ka Thermal a me nā Kemika.

Kiʻi kikoʻī

Hoʻolauna Huahana

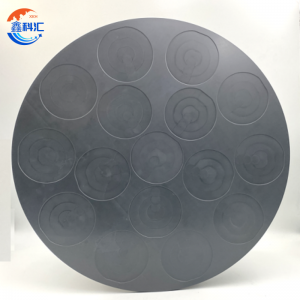

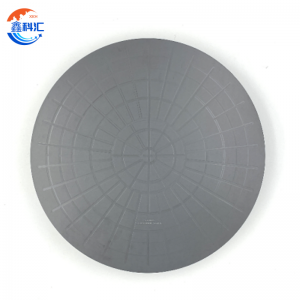

ʻO nā pā seramika Silicon carbide (SiC) nā ʻāpana hana kiʻekiʻe i hoʻohana nui ʻia i nā kaiapuni ʻoihana kiʻekiʻe, ka ukana kiʻekiʻe, a me ke kemika. Hoʻolālā ʻia mai nā mea hana silicon carbide ceramic kiʻekiʻe, ua hoʻolālā ʻia kēia mau pā e hāʻawi i ka ikaika mechanical ʻokoʻa, ʻoi aku ka maikaʻi o ka thermal conductivity, a me ke kūpaʻa maikaʻi loa i ka haʻalulu wela, oxidation, a me ka corrosion. ʻO ko lākou ʻano koʻikoʻi e kūpono loa iā lākou no nā noi ʻoihana like ʻole me ka hana semiconductor, ka hana photovoltaic, sintering o nā ʻāpana metallurgy pauka, a me nā mea hou aku.

ʻO nā pā carbide silikon e lilo i mea lawe a kākoʻo paha i ka wā o ka mālama ʻana i ka wela kahi e koʻikoʻi ai ka pololei o ka dimensional, ka pono o ke kūkulu ʻana, a me ke kūpaʻa kemika. Hoʻohālikelike ʻia i nā mea seramika kuʻuna e like me ka alumina a i ʻole mullite, hāʻawi nā pā SiC i ka hana kiʻekiʻe loa, ʻoi aku hoʻi i nā kūlana e pili ana i ke kaʻa kaʻa wela a me nā lewa hoʻonāukiuki.

Kaʻina Hana Hana & Hoʻohui Mea

ʻO ka hana ʻana o nā pā ceramic SiC e pili ana i ka ʻenehana pololei a me nā ʻenehana sintering kiʻekiʻe e hōʻoia i ka kiʻekiʻe kiʻekiʻe, microstructure like ʻole, a me ka hana mau. Aia nā ʻanuʻu maʻamau:

-

Koho Mea Maka

Koho ʻia ka pauka silicon carbide kiʻekiʻe (≥99%), pinepine me ka mana kikoʻī kikoʻī a me ka liʻiliʻi o nā haumia e hōʻoiaʻiʻo ai i nā waiwai mechanical a me ka wela. -

Hana Hana

Ma muli o nā kikoʻī o ka tray, hoʻohana ʻia nā ʻenehana hana ʻokoʻa:-

Cold Isostatic Pressing (CIP) no ke kiʻekiʻe-kiʻekiʻe, aʻaʻahu compacts

-

Extrusion a i ʻole hoʻoheheʻe paheʻe no nā ʻano paʻakikī

-

ʻO ka hoʻoheheʻe ʻana no nā geometries kikoʻī

-

-

Nā ʻenehana Sintering

Hoʻopili ʻia ke kino ʻōmaʻomaʻo ma nā wela kiʻekiʻe loa, ma ke ʻano he 2000°C, ma lalo o nā ea lewa a i ʻole. Aia nā ʻano hana sintering maʻamau:-

ʻO SiC i hoʻopaʻa ʻia i ka pane (RB-SiC)

-

SiC i hoʻopaʻa ʻia me ke kaomi ʻole (SSiC)

-

ʻO SiC i hoʻoheheʻe hou ʻia (RBSiC)

Loaʻa kēlā me kēia ʻano hana i nā ʻano waiwai like ʻole, e like me ka porosity, ka ikaika, a me ka conductivity thermal.

-

-

Mīkini pololei

Ma hope o ka sintering, ua mīkini ʻia nā pā e hoʻokō i nā ʻae ʻana o ka dimensional paʻa, ka hoʻopau ʻana i ka ʻili, a me ka palahalaha. Hiki ke hoʻohana ʻia nā lāʻau lapaʻau e like me ka lapping, grinding, a me ka polishing ma muli o nā pono o ka mea kūʻai aku.

Nā noi maʻamau

Hoʻohana ʻia nā pahu seramika Silicon carbide i nā ʻano ʻoihana like ʻole ma muli o ko lākou versatility a me ke kūpaʻa. Loaʻa nā noi maʻamau:

-

ʻOihana Semiconductor

Hoʻohana ʻia nā pā SiC e like me nā mea lawe i ka wafer annealing, diffusion, oxidation, epitaxy, a me nā kaʻina hana implantation. ʻO kā lākou kūpaʻa e hōʻoia i ka hāʻawi like ʻana o ka mahana a me ka liʻiliʻi o ka contamination. -

ʻOihana Photovoltaic (PV).

I ka hana ʻana o nā cell solar, kākoʻo nā pā SiC i nā ingots silicon a i ʻole nā wafers i ka wā o ka hoʻolaha ʻana o ka wela kiʻekiʻe a me nā ʻanuʻu sintering. -

Pauda Metallurgy a me Keramika

Hoʻohana ʻia no ke kākoʻo ʻana i nā ʻāpana i ka wā o ka sintering o nā pauka metala, nā seramika, a me nā mea hoʻohui. -

Pani aniani a me ka hoikeike

Hoʻohana ʻia e like me nā pā kiln a i ʻole nā papa no ka hana ʻana i nā aniani kūikawā, nā substrate LCD, a i ʻole nā mea ʻokoʻa ʻē aʻe. -

Ka Hana Kemika a me nā kapuahi wela

E lawelawe ma ke ʻano he mea lawe i ka corrosion i loko o nā reactors kemika a i ʻole ma ke ʻano he mau pā kākoʻo wela i loko o nā umu a me nā kapuahi hoʻomalu.

Nā hiʻohiʻona hana nui

-

✅Kūʻokoʻa Thermal Kūʻokoʻa

Kū i ka hoʻohana mau ʻana i nā mahana a hiki i 1600-2000 ° C me ka ʻole o ka warping a i ʻole degradation. -

✅Ikaika Mechanical Kiʻekiʻe

Hāʻawi i ka ikaika flexural kiʻekiʻe (maʻamau> 350 MPa), e hōʻoia ana i ka lōʻihi lōʻihi ma lalo o nā kūlana haʻahaʻa kiʻekiʻe. -

✅ʻO ke kū ʻana i ka haʻalulu wela

Hana maikaʻi i nā kaiapuni me ka wikiwiki o ka wela, e hōʻemi ana i ka pilikia o ka pohā. -

✅ʻO ke kū'ēʻana i kaʻinoʻino a me ka oxidation

Paʻa kemika i loko o ka hapa nui o nā ʻakika, alkalis, a me nā kinoea oxidizing/hōʻemi, kūpono no nā kaʻina kemika koʻikoʻi. -

✅ʻO ka pololei a me ka palahalaha

Mīkini i ke kiʻekiʻe kiʻekiʻe, e hōʻoia ana i ka hana like ʻana a me ka launa pū me nā ʻōnaehana automated. -

✅Ka lōʻihi o ke ola a me ke kumu kūʻai

ʻO nā kumukūʻai hoʻololi haʻahaʻa a hoʻemi ʻia nā kumukūʻai mālama e lilo ia i kumu kūʻai kūpono i ka manawa.

Nā Kūlana ʻenehana

| ʻĀpana | Waiwai maʻamau |

|---|---|

| Mea waiwai | Hoʻopaʻa ʻia ʻo SiC / SiC Sintered |

| Max. Ka Mahana Hana | 1600–2000°C |

| Ikaika Flexural | ≥350 MPa |

| ʻO ka mānoanoa | ≥3.0 g/cm³ |

| ʻO ka hoʻoili wela | ~120–180 W/m·K |

| Palahalaha o ka Ili | ≤ 0.1 mm |

| mānoanoa | 5–20 mm (hiki ke hoʻololi ʻia) |

| Anana | Kūlana: 200×200 mm, 300×300 mm, etc. |

| Hoʻopau ʻili | Mīkini, poni (ma ke noi) |

Nā nīnau i nīnau pinepine ʻia (FAQ)

Q1: Hiki ke hoʻohana ʻia nā pā carbide silicon i loko o nā umu ahi?

A:ʻAe, maikaʻi nā pā SiC no nā kaiapuni haʻahaʻa ma muli o ko lākou haʻahaʻa haʻahaʻa haʻahaʻa, kūpaʻa kemika, a me ke kū ʻana o ka wela kiʻekiʻe.

Q2: Loaʻa nā kiʻi maʻamau a i ʻole nā slot?

A:ʻOiaʻiʻo. Hāʻawi mākou i nā lawelawe hana maʻamau e like me ka nui o ka pā, ke ʻano, nā hiʻohiʻona o ka ʻili (e laʻa, nā grooves, nā lua), a me ka poli ʻili e hoʻokō i nā koi kūʻokoʻa o nā mea kūʻai aku.

Q3: Pehea e hoʻohālikelike ai ʻo SiC me nā alumina a i ʻole nā pā quartz?

A:ʻOi aku ka ikaika o SiC, ʻoi aku ka maikaʻi o ka wela, a me ke kūpaʻa maikaʻi i ka haʻalulu wela a me ka corrosion kemika. ʻOiai ʻoi aku ka maikaʻi o ka alumina, ʻoi aku ka maikaʻi o ka SiC i nā kaiapuni koi.

Q4: Aia kahi mānoanoa maʻamau no kēia mau pā?

A:ʻO ka mānoanoa ka mea maʻamau i ka laulā o 5-20 mm, akā hiki iā mākou ke hoʻoponopono iā ia ma muli o kāu noi a me nā koi hoʻouka.

Q5: He aha ka manawa alakaʻi maʻamau no nā pā SiC maʻamau?

A:Hoʻololi nā manawa alakaʻi ma muli o ka paʻakikī a me ka nui akā maʻamau mai 2 a 4 mau pule no nā kauoha maʻamau.

E pili ana iā mākou

Hoʻokumu ʻo XKH i ka hoʻomohala ʻenehana kiʻekiʻe, ka hana ʻana, a me ke kūʻai ʻana i nā aniani optical kūikawā a me nā mea aniani hou. Hāʻawi kā mākou huahana i nā uila uila, nā mea hoʻohana uila, a me ka pūʻali koa. Hāʻawi mākou i nā ʻāpana optical Sapphire, nā uhi kelepona kelepona paʻa, Ceramics, LT, Silicon Carbide SIC, Quartz, a me nā wafer kristal semiconductor. Me ka ʻike akamai a me nā mea hana ʻoki ʻoki, ʻoi aku mākou i ka hoʻoili huahana maʻamau ʻole, me ka manaʻo e lilo i alakaʻi optoelectronic material high-tech ʻoihana.