Hoʻolako ʻia ka paipu seramika Silicon carbide ceramic tray sucker silikon carbide ceramic tube hoʻolako kiʻekiʻe kiʻekiʻe sintering hana maʻamau

Nā hiʻohiʻona nui:

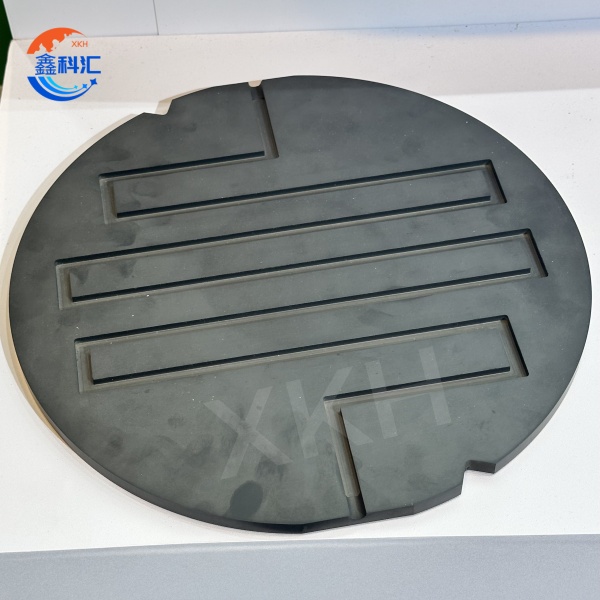

1. Silicon carbide ceramic pā

- ʻO ka paʻakikī kiʻekiʻe a me ke kūpaʻa ʻana: ua kokoke ka paʻakikī i ke daimana, a hiki ke kū i ka lole mechanical i ka hana wafer no ka manawa lōʻihi.

- ʻO ka conductivity thermal kiʻekiʻe a me ka coefficient hoʻonui haʻahaʻa haʻahaʻa: ka hoʻokuʻu ʻana o ka wela wikiwiki a me ke kūpaʻa dimensional, e pale ana i ka deformation i hana ʻia e ke kaumaha wela.

- ʻO ka palahalaha kiʻekiʻe a me ka hoʻopau ʻana o ka ʻili: ʻO ka palahalaha o ka ʻili a hiki i ka pae micron, e hōʻoiaʻiʻo ana i ka pili piha ma waena o ka wafer a me ka disk, e hōʻemi ana i ka haumia a me ka pōʻino.

Paʻa kemika: Ke kūpaʻa ikaika i ka corrosion, kūpono no ka hoʻomaʻemaʻe pulu a me nā kaʻina hana etching i ka hana semiconductor.

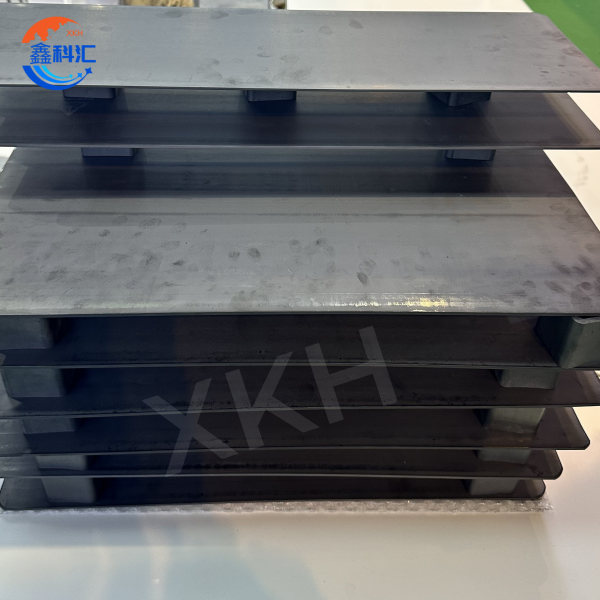

2. Silicon carbide ceramic paipu

- Ke kūpaʻa wela kiʻekiʻe: Hiki iā ia ke hana ma ke ʻano wela kiʻekiʻe ma luna o 1600 ° C no ka manawa lōʻihi, kūpono no ke kaʻina hana semiconductor kiʻekiʻe.

ʻOi aku ka pale ʻana i ka corrosion: kū i ka waika, alkalis a me nā ʻano mea hoʻoheheʻe kemika, kūpono no nā kaʻina hana paʻakikī.

- ʻO ka paʻakikī kiʻekiʻe a me ka pale ʻana i ka lole: pale i ka erosion particle a me ka lole mīkini, hoʻonui i ke ola lawelawe.

- ʻO ka conductivity thermal kiʻekiʻe a me ka coefficient haʻahaʻa o ka hoʻonui ʻana i ka wela: ka lawe wikiwiki ʻana o ka wela a me ke kūpaʻa dimensional, e hōʻemi ana i ka deformation a i ʻole ka haki ʻana ma muli o ke kaumaha wela.

Ka palena huahana:

Pilikino carbide seramika pā palena:

| (Waiwai waiwai) | (Ui) | (ssic) | |

| (Maʻiʻo SiC) | (Wt)% | >99 | |

| (Ka nui o ka palaoa maʻamau) | micron | 4-10 | |

| (Density) | kg/dm3 | >3.14 | |

| (Ka ʻike ʻia o ka porosity) | Vo1% | <0.5 | |

| (Vickers paakiki) | HV 0.5 | GPa | 28 |

| *() Ka ikaika wiliwili* (ʻekolu helu) | 20ºC | MPa | 450 |

| (Ka ikaika compressive) | 20ºC | MPa | 3900 |

| (Elastic Modulus) | 20ºC | GPa | 420 |

| (Oolea ha'iha'i) | MPa/m'% | 3.5 | |

| (Hana wela) | 20°ºC | W/(m*K) | 160 |

| (Ke kū'ē) | 20°ºC | ʻŌm.cm | 106-108 |

(Ka helu hoʻonui wela) | a(RT**...80ºC) | K-1*10-6 | 4.3 |

(Ka wela hana kiʻekiʻe loa) | oºC | 1700 | |

Silicon carbide ceramic tube parameter:

| Nā mea | Papa kuhikuhi |

| α-SIC | 99% min |

| ʻIke ʻia ka Porosity | 16% ka nui |

| ʻAiʻi Nui | 2.7g/cm3 min |

| Kulou ikaika ma ka wela kiekie | 100 Mpa min |

| Coefficient o ka hoonui wela | K-1 4.7x10 -6 |

| Coefficient of Thermal Conductivity(1400ºC) | 24 W/mk |

| Max. Ka Mahana Hana | 1650ºC |

Nā noi nui:

1. Silicon carbide seramika pā

- ʻOki ʻoki a me ka poli Wafer: lawelawe ma ke ʻano he paepae e hōʻoia i ka pololei kiʻekiʻe a me ka paʻa i ka wā o ka ʻoki a me ka polishing.

- Kaʻina hana Lithography: Hoʻopaʻa ʻia ka wafer i ka mīkini lithography e hōʻoia i ke kūlana kiʻekiʻe i ka wā o ka ʻike.

- Chemical Mechanical Polishing (CMP): hana ma ke ʻano he kahua kākoʻo no ka polishing pads, e hāʻawi ana i ke kaomi like ʻole a me ka hāʻawi ʻana i ka wela.

2. Silicon carbide ceramic paipu

- ʻO ka umu ahi wela kiʻekiʻe: hoʻohana ʻia no nā mea wela kiʻekiʻe e like me ka diffusion furnace a me ka oxidation furnace e lawe i nā wafers no ka mālama ʻana i ke kaʻina hana wela.

- Ke kaʻina hana CVD/PVD: Ma ke ʻano he paipu lawe i loko o ke keʻena pane, kū i nā wela kiʻekiʻe a me nā kinoea corrosive.

- Nā lako lako Semiconductor: no nā mea hoʻololi wela, nā paipu kinoea, a me nā mea ʻē aʻe, e hoʻomaikaʻi i ka hoʻokele wela o nā lako.

Hāʻawi ʻo XKH i kahi ʻano lawelawe maʻamau no nā pā seramika silicon carbide, nā kīʻaha suction a me nā paipu ceramic silicon carbide. Silicon carbide ceramic trays a me nā kīʻaha suction, XKH hiki ke hoʻopilikino ʻia e like me nā koi o ka mea kūʻai aku o nā ʻano nui like ʻole, nā ʻano a me ka ʻili o ka ʻili, a kākoʻo i ka mālama ʻana i ka uhi kūikawā, hoʻomaikaʻi i ke kūpaʻa a me ka pale ʻana i ka corrosion; No nā paipu seramika silicon carbide, hiki i ka XKH ke hana i nā ʻano like ʻole o ke anawaena o loko, ke anawaena o waho, ka lōʻihi a me ke ʻano paʻakikī (e like me ke ʻano o ka tube a i ʻole ka porous tube), a hāʻawi i ka polishing, anti-oxidation coating a me nā kaʻina hana lapaʻau ʻē aʻe. Hōʻoia ka XKH e hiki i nā mea kūʻai ke hoʻohana piha i nā pono hana o nā huahana silicon carbide ceramic e hoʻokō i nā koi koi o nā māla hana kiʻekiʻe e like me semiconductors, led a me photovoltaics.

Kiʻi kikoʻī