Hiki ke hoʻohana ʻia ka mīkini paʻi laser papa liʻiliʻi 1000W-6000W ka liʻiliʻi liʻiliʻi 0.1MM no nā mea aniani metala.

Nā mea pili

1. Nā mea metala: e like me ke aluminika, ke keleawe, ka titanium alloy, ke kila kila, a pēlā aku.

2. Non-metallic mea: e like me ka plastic (me ka polyethylene PE, polypropylene PP, polyester PET a me nā kiʻiʻoniʻoni'ē aʻe), aniani (me ke aniani maʻamau, ke aniani kūikawā e like me ke aniani ultra-keʻokeʻo, ke aniani K9, ke aniani borosilicate kiʻekiʻe, ke aniani quartz, etc.

3. Mea hoʻohuihui: i haku ʻia me ʻelua a ʻoi aku paha nā mea me nā waiwai like ʻole ma o ke ʻano kino a i ʻole kemika, me nā waiwai piha maikaʻi loa.

4. Nā mea kūikawā: Ma nā wahi kiko'ī, hiki ke hoʻohanaʻia nā mīkini punching laser e hana i kekahi mau mea kūikawā.

Nā ʻāpana kikoʻī

| Inoa | ʻIkepili |

| Mana laser: | 1000W-6000W |

| ʻOki pololei: | ±0.03MM |

| Aperture waiwai liʻiliʻi: | 0.1MM |

| Ka lōʻihi o ka ʻoki ʻana: | 650MM×800MM |

| Pololei kūlana: | ≤±0.008MM |

| Ka pololei hou: | 0.008MM |

| ʻOki kinoea: | Ea |

| kükohu pa'a: | Pneumatic lihi lihi, kākoʻo paʻa |

| Pūnaehana hoʻokele: | Mākēneki hoʻokuʻu laina laina |

| Mānoanoa ʻokiʻoki | 0.01MM-3MM |

Nā pōmaikaʻi ʻenehana

1.Efficient drilling: ʻO ka hoʻohanaʻana i ka laser beam kiʻekiʻe no ka hoʻopiliʻoleʻana, wikiwiki, 1 kekona e hoʻopau i ka hanaʻana i nā puka liʻiliʻi.

2.High precision: Ma ka hoʻomalu ponoʻana i ka mana, ka pulse frequency a me ka nānāʻana i ke kūlana o ka laser, hiki ke hoʻokō i ka hana wili me ka micron precision.

3. Hoʻohana nuiʻia: hiki ke hana i nāʻano brittle, paʻakikī i ka hana a me nā mea kūikawā, e like me ka plastic, rubber, metala (stainless steel, aluminum, copper, titanium alloy, etc.), aniani, keramika a pēlā aku.

4. Hana akamai: Hoʻolako ʻia ka mīkini punching laser me ka ʻōnaehana mana helu kiʻekiʻe, ʻoi aku ka naʻauao a maʻalahi hoʻi e hoʻohui me ka hoʻolālā kōkua kamepiula a me ka ʻōnaehana hana kōkua kamepiula e ʻike ai i ka hoʻonohonoho wikiwiki ʻana a me ka optimization o ka pass paʻakikī a me ke ala hana.

Kūlana hana

1.Diversity: hiki ke hoʻokō i nā ʻano hana puka paʻakikī like ʻole, e like me nā puka poepoe, nā lua kūhāhā, nā lua triangle a me nā puka kūikawā ʻē aʻe.

2.High quality: He kiʻekiʻe ka maikaʻi o ka lua, maʻemaʻe ka lihi, ʻaʻohe manaʻo ʻino, a liʻiliʻi ka deformation.

3.Automation: Hiki iā ia ke hoʻopau i ka hana micro-hole me ka nui aperture like a me ka hāʻawi like ʻana i ka manawa hoʻokahi, a kākoʻo i ka hana hole hui me ka ʻole o ka hana lima.

Nā hiʻohiʻona lako

■ liʻiliʻi liʻiliʻi o nā mea hana, e hoʻoponopono i ka pilikia o kahi ākea.

■ Kiʻekiʻe kiʻekiʻe, hiki i ka puka kiʻekiʻe ke hiki i 0.005mm.

■ He maʻalahi ka hana a me ka maʻalahi o ka hoʻohana.

■ Hiki ke hoʻololiʻia ke kumu kukui e like me nā mea likeʻole, aʻoi aku ka ikaika o ka pilina.

■ He wahi liʻiliʻi i hoʻopilikia ʻia i ka wela, emi ka oxidation a puni nā lua.

Kahua noi

1. ʻOihana uila

●Printed Circuit Board (PCB) kuʻi:

ʻO ka mīkini Microhole: Hoʻohana ʻia no ka hana ʻana i nā microhole me ke anawaena o ka liʻiliʻi ma mua o 0.1mm ma PCBS e hoʻokō i nā pono o nā papa kiʻekiʻe kiʻekiʻe interconnect (HDI).

Nā puka makapō a kanu ʻia: Ka hana ʻana i nā puka makapō a kanu ʻia i nā PCBS multi-layer e hoʻomaikaʻi i ka hana a me ka hoʻohui ʻana o ka papa.

●Semiconductor paʻi:

Ka hoʻoheheʻe ʻana i ka papa alakaʻi: Hoʻohana ʻia nā puka kikoʻī i loko o ke kumu alakaʻi semiconductor no ka hoʻopili ʻana i ka chip i ke kaapuni waho.

Kokua ʻoki ʻoki Wafer: E ʻoki i nā lua i ka wafer e kōkua i nā kaʻina hana ʻoki a me ka hoʻopili ʻana.

2. Mekini pololei

●Ka hana ʻana i nā ʻāpana liʻiliʻi:

ʻO ka hoʻoheheʻe ʻana i nā mea hana pololei: Ka hana ʻana i nā puka kikoʻī kiʻekiʻe ma nā mīkini micro no nā ʻōnaehana hoʻouna pololei.

ʻO ka hoʻoheheʻe ʻana i nā ʻāpana sensor: ʻO ka mīkini microhole ma nā ʻāpana ʻike e hoʻomaikaʻi i ka naʻau a me ka wikiwiki o ka pane.

● ʻO ka hana ʻana i ka mold:

ʻO ka lua hoʻoluʻu: ʻO ka lua hoʻoluʻu mīkini ma luna o ka pahu hoʻoheheʻe a i ʻole ka hoʻoheheʻe ʻana i ka mold no ka hoʻokō ʻana i ka hana wela o ka mold.

Ka hana ʻana o ka puka makani: ʻO ka mīkini ʻana i nā puka makani liʻiliʻi ma ka poʻi e hōʻemi i nā hemahema.

3. Nā mea lapaʻau

● ʻO nā mea hana ʻokiʻoki liʻiliʻi liʻiliʻi:

ʻO ka catheter perforation: Hoʻohana ʻia nā microhole i nā catheters hōʻoki liʻiliʻi no ka lawe ʻana i ka lāʻau a i ʻole ka hoʻokahe wai.

Nā ʻāpana Endoscope: Hoʻohana ʻia nā lua pololei i ka lens a i ʻole ke poʻo mea hana o ka endoscope e hoʻomaikaʻi i ka hana o ka mea kani.

● Pūnaehana lawe lāʻau:

ʻO ka hoʻoheheʻe ʻana i ka microneedle array: ʻO ka hana ʻana i nā microhole ma kahi lāʻau lapaʻau a i ʻole ka microneedle array no ka mālama ʻana i ka nui o ka hoʻokuʻu ʻana i ka lāʻau.

ʻO ka hoʻoheheʻe biochip: Hoʻohana ʻia nā microhole ma nā biochips no ka moʻomeheu cell a i ʻole ka ʻike.

4. ʻO nā mea ʻenehana

●Fiber optic mea hoʻohui:

ʻO ka hoʻoheheʻe ʻana i ka lua o ka fiber Optical: ʻO nā microhole mīkini ma ka ʻaoʻao hope o ka mea hoʻohui optical e hoʻomaikaʻi i ka pono o ka hoʻouna ʻana i ka hōʻailona.

Mīkini lāʻau fiber: ʻO ka hana ʻana i nā puka kikoʻī kiʻekiʻe ma luna o ka pā hoʻonohonoho fiber no ke kamaʻilio ʻana i nā ʻano ʻano he nui.

●Kānana Optical:

Kānana kānana: ʻO nā microhole mīkini ma ka kānana optical e hoʻokō i ke koho ʻana i nā lōʻihi nalu kikoʻī.

Mīkini mea ʻokoʻa: Mīkini i nā microhole ma luna o nā mea ʻokoʻa ʻokoʻa no ka ʻoki ʻana a i ʻole ka hana ʻana i ka kukuna laser.

5. Hana kaʻa

● ʻōnaehana hoʻoheheʻe wahie:

ʻO ke kuʻi ʻana i ka nozzle injection: Ka hoʻoponopono ʻana i nā micro-hole ma ka nozzle injection e hoʻomaikaʻi i ka hopena atomization wahie a hoʻomaikaʻi i ka pono o ka puhi ʻana.

●Ka hana ʻana i nā mea ʻike:

ʻO ka ʻeli ʻana i ka ʻenekona kaomi: ʻO nā microhole mīkini ma ka diaphragm sensor e hoʻomaikaʻi i ka naʻau a me ka pololei o ka ʻike.

●Pākeke mana:

ʻO ka hoʻoheheʻe ʻana i ka pahu pahu pahu: ʻO nā microhole mīkini ma nā pahu pahu pahu lithium e hoʻomaikaʻi ai i ka hoʻokomo ʻana o ka electrolyte a me ka lawe ʻana i ka ion.

Hāʻawi ʻo XKH i nā lawelawe holoʻokoʻa holoʻokoʻa no nā perforators laser papa liʻiliʻi, ʻo ia hoʻi akā ʻaʻole i kaupalena ʻia i: Kūkākūkā kūʻai ʻoihana, hoʻolālā papahana maʻamau, lako lako lako kiʻekiʻe, hoʻonohonoho maikaʻi a me ka hoʻonohonoho ʻana, hoʻomaʻamaʻa kikoʻī hana, e hōʻoia i ka loaʻa ʻana o nā mea kūʻai i ka ʻike lawelawe ʻoi aku ka maikaʻi, pololei a mālama ʻole i ke kaʻina hana punching.

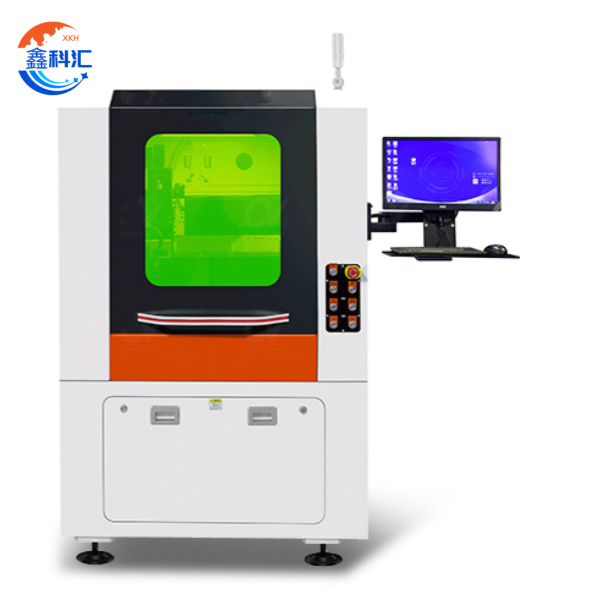

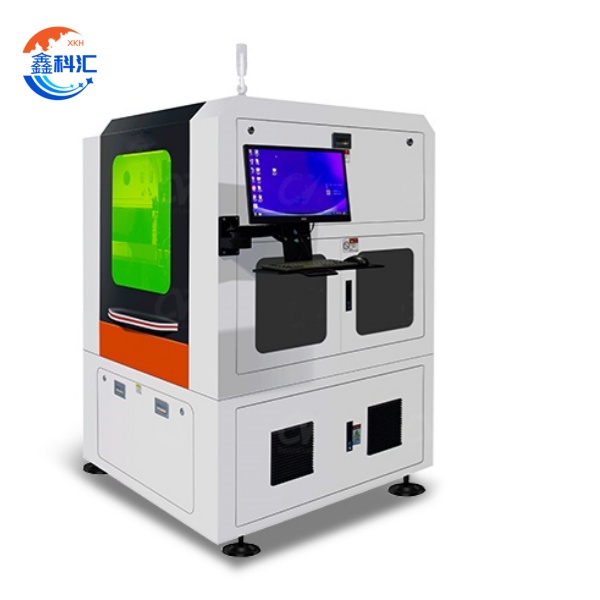

Kiʻi kikoʻī