Nā pani aniani ʻo TGV 12 ʻīniha wafer Puni aniani

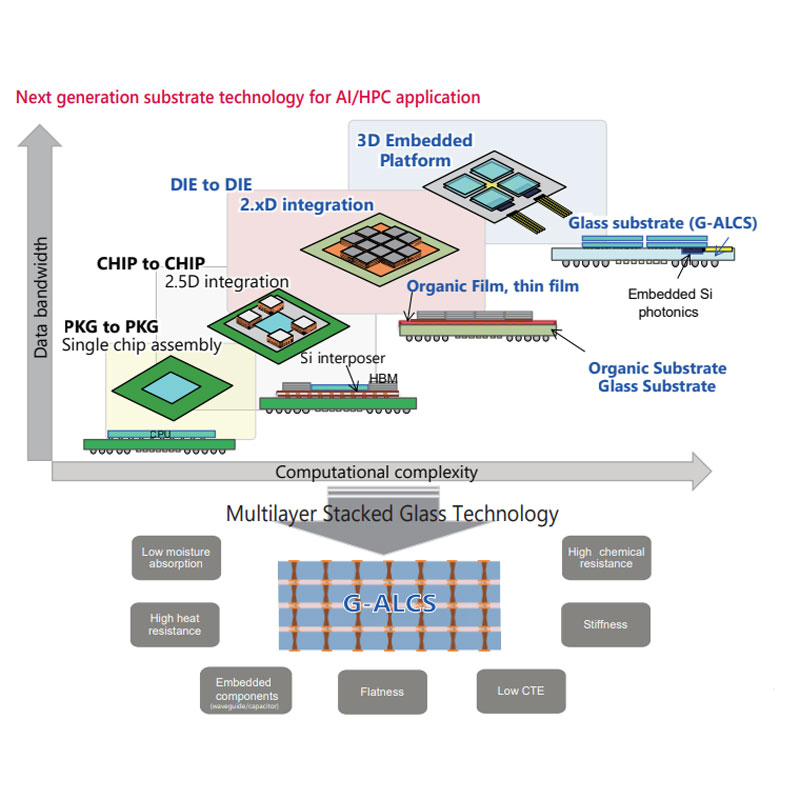

ʻOi aku ka maikaʻi o nā substrate aniani ma ke ʻano o nā mea wela, kūpaʻa kino, a ʻoi aku ka wela a ʻoi aku ka liʻiliʻi o ka warping a i ʻole nā pilikia deformation ma muli o nā wela kiʻekiʻe;

Eia kekahi, ʻo nā waiwai uila kūikawā o ke kīʻaha aniani e ʻae i nā poho dielectric haʻahaʻa, e ʻae ana i ka hōʻailona maʻemaʻe a me ka lawe mana. ʻO ka hopena, hoʻemi ʻia ka nalowale o ka mana i ka wā o ka hoʻouna ʻana i nā hōʻailona a hoʻonui maoli ʻia ka hana holoʻokoʻa o ka chip. Hiki ke hoʻemi ʻia ka mānoanoa o ka ipu aniani ma kahi o ka hapalua e hoʻohālikelike ʻia me ka plastic ABF, a hoʻomaikaʻi ka thinning i ka wikiwiki o ka hoʻouna ʻana i ka hōʻailona a me ka pono o ka mana.

ʻenehana hana hole o TGV:

Hoʻohana ʻia ke ʻano hana etching laser no ka hoʻoulu ʻana i ka wahi denaturation mau ma o ka laser pulsed, a laila hoʻokomo ʻia ke aniani i mālama ʻia i loko o ka hydrofluoric acid solution no ka etching. ʻOi aku ka wikiwiki o ka etching rate o ke aniani ʻāpana denaturation i loko o ka waika hydrofluoric ma mua o ke aniani undenatured e hana ʻia ma nā lua.

Hoʻopiha TGV:

ʻO ka mua, hana ʻia nā puka makapō TGV. ʻO ka lua, ua waiho ʻia ka papa hua i loko o ka lua makapō TGV e ka hoʻoheheʻe kino kino (PVD). ʻO ke kolu, hiki i ka electroplating lalo i ka hoʻopiha piha ʻana o TGV; ʻO ka hope, ma o ka hoʻopaʻa ʻana i ka manawa, ka wili ʻana i hope, ka ʻike keleawe me ka mechanical polishing (CMP), ka wehe ʻole ʻana, e hana ana i kahi pā hoʻololi i piha i ka metala TGV.

Kiʻi kikoʻī