Pūnaehana Kūlana Wafer no ke ana ʻana i ke ʻano Crystal

Mea hoʻolauna

ʻO nā mea hana Wafer orientation nā mea kikoʻī e pili ana i nā loina X-ray diffraction (XRD), i hoʻohana mua ʻia i ka hana semiconductor, nā mea optical, ceramics, a me nā ʻoihana ʻenehana crystalline.

Hoʻoholo kēia mau mea hana i ka hoʻonohonoho ʻana i ka lattice crystal a alakaʻi i nā kaʻina hana ʻoki a polū paha. Aia nā hiʻohiʻona nui:

- Nā ana pololei kiʻekiʻe:Hiki ke hoʻonā i nā mokulele crystallographic me nā hoʻonā angular a hiki i ka 0.001°.

- ʻO ka hoʻohālikelike nui ʻana:Kākoʻo i nā wafers a hiki i 450 mm ke anawaena a me ke kaupaona ʻana o 30 kg, kūpono i nā mea like me ka silicon carbide (SiC), sapphire, a me ka silicon (Si).

- Hoʻolālā modular:ʻO nā hana hiki ke hoʻonui ʻia me ka nānā ʻana i ka curve curve, 3D surface defect mapping, a me ka hoʻopaʻa ʻana i nā mea hana no ka hoʻoili ʻana i nā laʻana.

Nā ʻāpana ʻenehana nui

| Māhele Māhele | Nā Waiwai maʻamau/Hoʻonohonoho |

| Puna X-ray | Cu-Kα (0.4×1 mm kiko kiko), 30 kV e hoʻokē ana i ka uila, 0–5 mA hiki ke hoʻololi ʻia. |

| ʻO ka laulā angular | θ: -10° a i +50°; 2θ: -10° a i +100° |

| Ka pololei | ʻO ka hoʻonā ʻana o ke kihi ʻokiʻoki: 0.001°, ʻike kīnā ʻia o ka ʻili: ±30 arcseconds (ka ʻāwili ʻana) |

| ʻO ka māmā ʻimi ʻana | Hoʻopau ʻo Omega scan i ka hoʻonohonoho lattice piha i 5 kekona; Lawe ʻo Theta scan iā ~1 minuke |

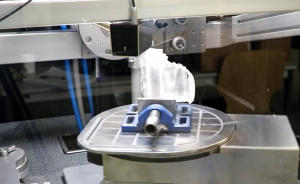

| ʻĀpana Laʻana | V-groove, pneumatic suction, multi-angle rotation, kūpono me 2-8-inihi wafers |

| Nā Hana Hoʻonui | ʻO ka nānā ʻana i ka ʻāʻī haʻalulu, ka palapala ʻāina 3D, ka mea hoʻopaʻa ʻana, ka ʻike kīnā ʻike (nā ʻōpala, GBs) |

Ke Kumu Hana

1. X-ray Diffraction Foundation

- Hoʻopili nā kukui X me ka nuclei atomika a me nā electrons i loko o ka lattice kristal, e hana ana i nā ʻano hoʻohālikelike. Hoʻoponopono ke kānāwai o Bragg (nλ = 2d sinθ) i ka pilina ma waena o nā kihi ʻokoʻa (θ) a me ka mokowā lattice (d).

Hopu nā mea ʻike i kēia mau hiʻohiʻona, i kālailai ʻia e kūkulu hou i ke ʻano crystallographic.

2. ʻO ka ʻenehana nānā ʻana i ka Omega

- Holo mau ke aniani a puni kahi axis paʻa i ka wā e hoʻomālamalama ana nā kukui X.

- E hōʻiliʻili nā mea ʻike i nā hōʻailona diffraction ma waena o nā mokulele crystallographic, hiki ke hoʻoholo piha i ka lattice orientation i 5 kekona.

3. ʻIkepili ʻAha ʻAha

- ʻO ka ʻoki aniani paʻa me nā ʻokoʻa ʻokoʻa X-ray e ana i ka laula kiʻekiʻe (FWHM), e nānā ana i nā hemahema o ka lattice a me ke kānana.

4. Ka Hoomalu Aunoa

- Hiki i ka PLC a me ka touchscreen interface ke hiki i nā kihi ʻoki i hoʻonohonoho ʻia, ka manaʻo manawa maoli, a me ka hoʻohui ʻana me nā mīkini ʻoki no ka mana pani pani.

Nā pono a me nā hiʻohiʻona

1. Ka pololei a me ka pono

- ʻO ka pololei pololei ± 0.001°, ka hoʻonā ʻike hemahema <30 arcseconds.

- ʻO ka wikiwiki o ka Omega scan he 200x ka wikiwiki ma mua o ka Theta scans.

2. Modularity a me Scalability

- Hiki ke hoʻonui ʻia no nā noi kūikawā (e laʻa, SiC wafers, turbine blades).

- Hoʻohui pū me nā ʻōnaehana MES no ka nānā ʻana i ka hana manawa maoli.

3. Kūlike a me ke kūpaʻa

- Hoʻokomo i nā laʻana like ʻole ke ʻano (e laʻa, nā ʻāpana sapphire māwae).

- Hoʻoemi ka hoʻolālā ʻana i ka ea i nā pono mālama.

4. ʻO ka hana akamai

- Hoʻokahi kaomi calibration a me ka hana nui-hana.

- Auto-calibration me nā kristal kuhikuhi e hōʻemi i ka hewa kanaka.

Nā noi

1. Hana Hana Semiconductor

- Wafer dicing orientation: Hoʻoholo i ka Si, SiC, GaN wafer orientation no ka ʻoki pono ʻana.

- ʻO ka palapala ʻāina hemahema: E ʻike i nā ʻōpala a i ʻole nā dislocations e hoʻomaikaʻi i ka hua chip.

2. ʻO nā mea ʻenehana

- Nā kristal nonlinear (e laʻa, LBO, BBO) no nā mea laser.

- Sapphire wafer reference surface marking for LED substrates.

3. Keramika a me nā Composites

- Nānā i ka hoʻonohonoho ʻana i ka palaoa ma Si3N4 a me ZrO2 no nā noi wela kiʻekiʻe.

4. Noiʻi a me ka mana maikaʻi

- Nā kulanui/keʻena hana no ka hoʻomohala ʻana i nā mea hou (e laʻa, nā alloys high-entropy).

- ʻOihana QC e hōʻoia i ka paʻa o ka hui.

Nā lawelawe a XKH

Hāʻawi ʻo XKH i ke kākoʻo ʻenehana holoʻokoʻa holoʻokoʻa no nā mea hana wafer orientation, me ka hoʻokomo ʻana, ka hoʻoponopono ʻana i nā ʻāpana kaʻina, ka nānā ʻana i ka curve curve, a me ka palapala ʻāina kīnā 3D. Hāʻawi ʻia nā hoʻonā i hoʻohālikelike ʻia (e laʻa, ka ʻenehana hoʻopaʻa ʻana i ka ingot) e hoʻomaikaʻi i ka semiconductor a me ka hoʻomohala ʻana i nā mea optical ma luna o 30%. Ke alakaʻi nei kahi hui hoʻolaʻa i ka hoʻomaʻamaʻa ma ka pūnaewele, ʻoiai ʻo 24/7 kākoʻo mamao a me ka hoʻololi ʻana i nā ʻāpana ʻāpana wikiwiki e hōʻoia i ka hilinaʻi o nā lako.