12 'īniha piha 'akomi pololei dicing saw lako wafer hoʻolaʻa 'okiʻoki pūnaewele no Si/SiC & HBM (Al)

Nā palena ʻenehana

| ʻĀpana | Hōʻike |

| Nui Hana | Φ8", Φ12" |

| Spindle | axis pālua 1.2/1.8/2.4/3.0, Max 60000 rpm |

| Lahi Lahi | 2" ~ 3" |

| Y1 / Y2 Axis

| Hoʻonui ʻanuʻu hoʻokahi: 0.0001 mm |

| Ka pololei o ka hoonoho ana: < 0.002 mm | |

| ʻO ka ʻoki ʻana: 310 mm | |

| X Axis | Ka nui o ka māmā hānai: 0.1–600 mm/s |

| Z1 / Z2 Axis

| Hoʻonui ʻanuʻu hoʻokahi: 0.0001 mm |

| ʻO ka pololei o ke kau ʻana: ≤ 0.001 mm | |

| θ Axis | Ka pololei o ke kūlana: ±15" |

| Hale Hoomaemae

| ʻO ka wikiwiki o ka hoʻololi: 100-3000 rpm |

| Ke ʻano hoʻomaʻemaʻe: Holoi kaʻa a milo-maloʻo | |

| Voltage Hana | 3 ʻāpana 380V 50Hz |

| Ana (W×D×H) | 1550×1255×1880 mm |

| Kaumaha | 2100 kg |

Kumu Hana

Loaʻa i nā mea hana ke ʻoki kiʻekiʻe ma o nā ʻenehana penei:

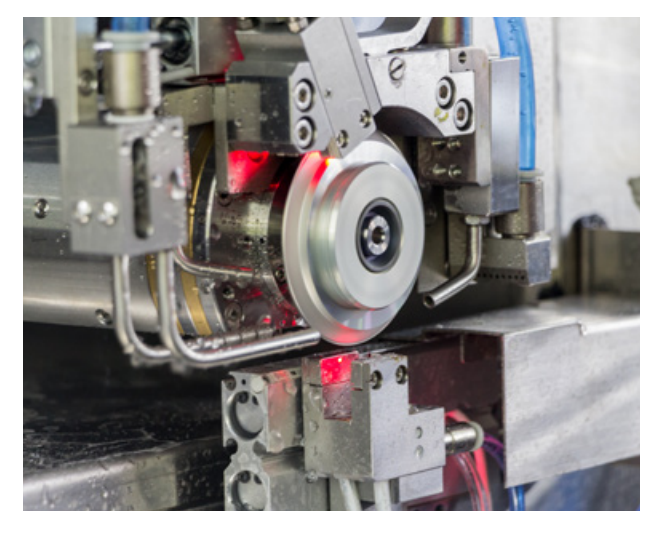

1.High-Rigidity Spindle System: Rotational speed a hiki i 60,000 RPM, i lako me na daimana a i ole laser cutting poo e hoololi ai i na waiwai waiwai.

2.Multi-Axis Motion Control: X / Y / Z-axis positioning accuracy o ± 1μm, hui pū me nā unahi kiʻekiʻe kiʻekiʻe e hōʻoia i nā ala ʻoki ʻole deviation.

3.Intelligent Visual Alignment: High-resolution CCD (5 megapixels) ʻike 'akomi i ke oki alanui a hoʻopaʻi no ka hoʻopaʻa ʻana a i ʻole ka misalignment.

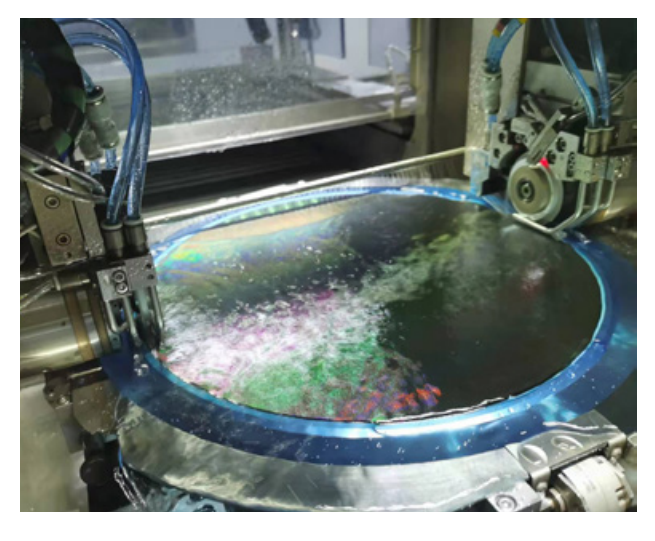

4.Cooling & Dust Wehe: Hoʻohui ʻia ka ʻōnaehana hoʻoheheʻe wai maʻemaʻe a me ka hoʻoneʻe ʻana i ka lepo lepo e hoʻemi i ka hopena wela a me ka hoʻohaumia ʻana.

Nā ʻano ʻoki

1.Blade Dicing: He kūpono no nā mea semiconductor kuʻuna e like me Si a me GaAs, me nā laula kerf o 50-100μm.

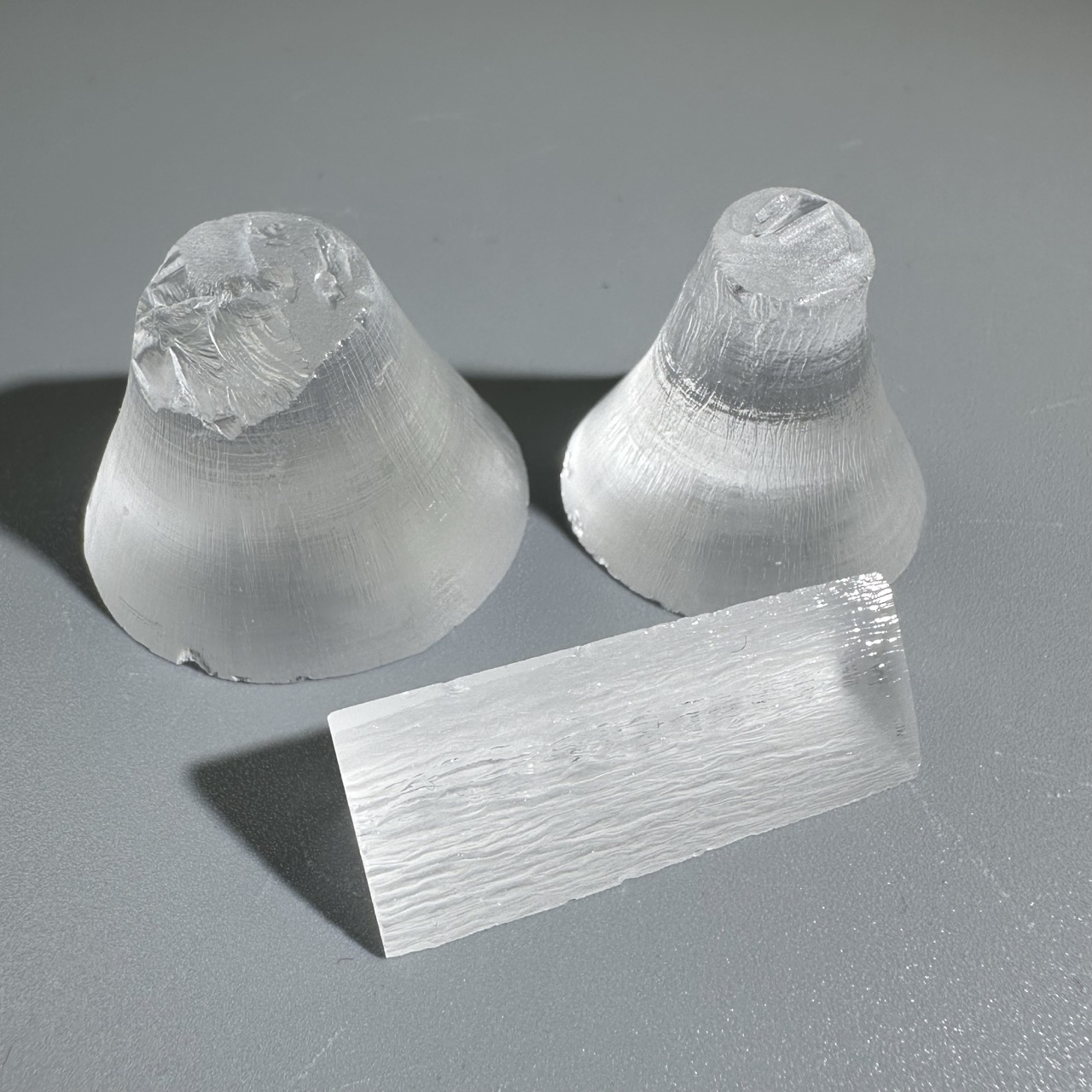

2.Stealth Laser Dicing: Hoʻohana ʻia no nā wafers ultra-thin (<100μm) a i ʻole nā mea palupalu (e laʻa, LT / LN), hiki ke hoʻokaʻawale ʻole i ke kaumaha.

Nā noi maʻamau

| Mea Pono | Kahua noi | Nā Koina Hana |

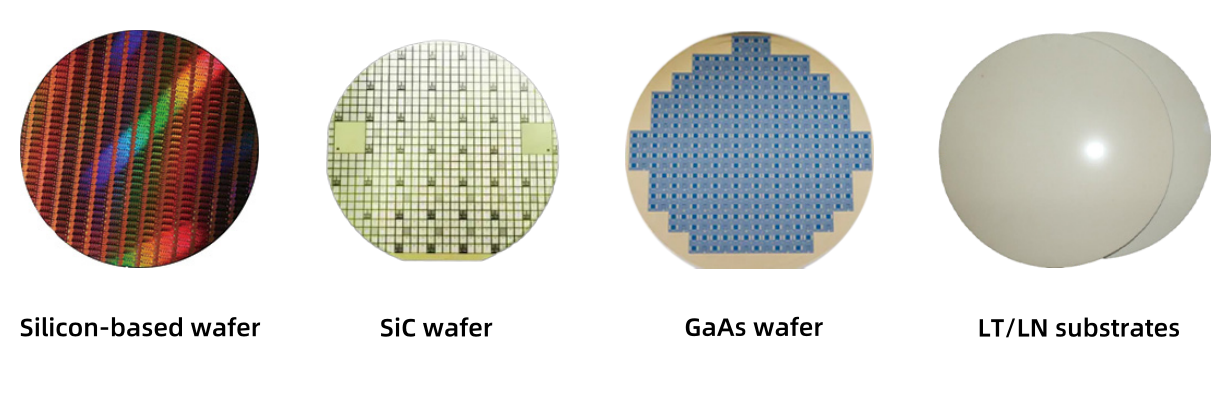

| Silika (Si) | Nā IC, nā mea ʻike MEMS | ʻOki kiʻekiʻe, ʻokiʻoki <10μm |

| Kapili Silika (SiC) | Mea mana (MOSFET/diodes) | ʻOki haʻahaʻa haʻahaʻa, hoʻokele hoʻokele wela |

| Gallium Arsenide (GaAs) | Nā mea RF, nā ʻāpana optoelectronic | Kāohi micro-crack, hoʻomaʻemaʻe hoʻomaʻemaʻe |

| LT/LN Lapu | Nā kānana SAW, nā modulators optical | ʻOki ʻole ke kaumaha, mālama i nā waiwai piezoelectric |

| ʻO nā ʻāpana seramika | ʻO nā modula mana, ka pahu LED | ʻO ka hana ʻana i nā mea paʻakikī kiʻekiʻe, palahalaha lihi |

| Nā Pākuʻi QFN/DFN | ʻO ka hoʻopili kiʻekiʻe | ʻOki hoʻokahi multi-chip, hoʻokō pono |

| WLCSP Wafers | Puke ʻili wafer | ʻO ka dicing me ka pōʻino ʻole o nā wafers ultra-thin (50μm) |

Nā pono

1. Kiʻekiʻe-wikiwiki kiʻi kiʻi kiʻi me ka collision pale 'ala alarma, wikiwiki hoʻololi kūlana, a me ka ikaika hewa-hooponopono.

2. Hoʻonui ʻia ke ʻano ʻoki ʻelua-spindle, hoʻomaikaʻi i ka pono ma kahi o 80% i hoʻohālikelike ʻia me nā ʻōnaehana hoʻokahi-spindle.

3. ʻO nā wili poepoe i lawe ʻia mai me ka pololei, nā alakaʻi laina, a me ka mana Y-axis grating scale i pani ʻia-loop control, e hōʻoia ana i ka paʻa lōʻihi o ka mīkini kiʻekiʻe.

4. ʻO ka hoʻouka ʻana a me ka wehe ʻana, ka hoʻololi ʻana i ke kūlana, ka ʻoki ʻana, a me ka nānā ʻana i ke kerf, e hōʻemi nui ana i ka hana o ka mea hana (OP).

5.Gantry-style spindle mounting structure, me ka liʻiliʻi loa lua-blade spacing o 24mm, e hiki ai ke hoʻololi ākea no nā kaʻina ʻoki ʻoki ʻelua-spindle.

Nā hiʻohiʻona

1. High-precision non-contact ana kiʻekiʻe.

2.Multi-wafer pālua-blade ʻoki ma kahi pā hoʻokahi.

3.Automatic calibration, kerf inspection, and blade breakage detection system.

4. Kākoʻo i nā kaʻina hana like ʻole me nā algorithm alignment maʻalahi hiki ke koho.

5.Fault pono-hoʻoponopono functionality a me ka maoli-manawa nui-kūlana nānā.

6. ʻoki ʻoki mua i ka hiki ma hope o ka dicing mua.

7.Customizable factory automation modules a me na hana koho.

Nā lako lako

Hāʻawi mākou i ke kākoʻo piha mai ke koho ʻana i nā mea hana a hiki i ka mālama lōʻihi:

(1) Hoʻomohala Kūʻai

· Manaʻo i nā hāʻina ʻoki ʻoki a me ka laser e pili ana i nā waiwai waiwai (e laʻa, ʻo SiC paʻakikī, ʻo GaAs brittleness).

· Hāʻawi i ka hoʻāʻo manuahi manuahi e hōʻoia i ka maikaʻi o ka ʻoki ʻana (me ka ʻoki ʻana, ka laula kerf, ka ʻeleʻele o ka ʻili, a pēlā aku).

(2) Hoʻomaʻamaʻa ʻenehana

· Hoʻomaʻamaʻa kumu: Ka hana ʻana i nā lako, hoʻoponopono ʻana i nā ʻāpana, mālama maʻamau.

· Nā Papa Kiʻekiʻe: ʻO ka loiloi kaʻina hana no nā mea paʻakikī (e laʻa, ke ʻoki ʻana i ke kaumaha o nā substrates LT).

(3) Kākoʻo ma hope o ke kūʻai aku

· 24/7 Pane: Nā diagnostics mamao a i ʻole kōkua ma ka pūnaewele.

· Hāʻawi i nā ʻāpana ʻokoʻa: ʻO nā spindles i hoʻopaʻa ʻia, nā ʻili, a me nā ʻāpana optical no ke pani wikiwiki.

· Hoʻopaʻa hoʻomalu: Hoʻoponopono maʻamau e mālama i ka pololei a hoʻonui i ke ola lawelawe.

ʻO kā mākou pono

✔ ʻIke ʻOihana: E lawelawe ana ma kahi o 300+ honua semiconductor a me nā mea hana uila.

✔ ʻenehana ʻokiʻoki: ʻO nā alakaʻi laina pololei a me nā ʻōnaehana servo e hōʻoia i ka paʻa o ka ʻoihana.

✔ Pūnaehana lawelawe honua: Ka uhi ʻana ma Asia, ʻEulopa, a me ʻAmelika ʻĀkau no ke kākoʻo kūloko.

No ka hoʻāʻo ʻana a i ʻole ka nīnau ʻana, e kelepona mai iā mākou!