8Inch 200mm 4H-N SiC Wafer Conductive dummy papa noiʻi

Ma muli o kāna mau waiwai kino a me ka uila, hoʻohana ʻia ka 200mm SiC wafer semiconductor material e hana i nā mea uila kiʻekiʻe, kiʻekiʻe-mehana, radiation-resistant, a me nā mea uila uila kiʻekiʻe. Ke emi mālie nei ke kumukūʻai substrate 8inch SiC i ka ulu ʻana o ka ʻenehana a ulu ka noi. Ke alakaʻi nei nā hoʻomohala ʻenehana hou i ka hana ʻana i ka nui o ka hana ʻana o 200mm SiC wafers. ʻO nā pōmaikaʻi nui o nā mea semiconductor wafer SiC i ka hoʻohālikelike ʻana me nā wafers Si a me GaAs: ʻO ka ikaika o ke kahua uila o 4H-SiC i ka wā o ka hāʻule ʻana o ka avalanche ʻoi aku ka nui ma mua o ka nui o nā waiwai kūpono no Si a me GaAs. Ke alakaʻi nei kēia i kahi emi nui o ka resistivity ma ka mokuʻāina ʻo Ron. ʻO ka resistivity haʻahaʻa ma ka mokuʻāina, i hui pū ʻia me ke kiʻekiʻe o kēia manawa a me ka conductivity thermal, hiki ke hoʻohana i ka make liʻiliʻi loa no nā mea mana. ʻO ka conductivity thermal kiʻekiʻe o SiC e hōʻemi i ka pale wela o ka chip. ʻO nā waiwai uila o nā mea i hoʻokumu ʻia i nā wafers SiC e paʻa loa i ka manawa a ma ka paʻa wela, kahi e hōʻoia ai i ka hilinaʻi kiʻekiʻe o nā huahana. Paʻa loa ʻo Silicon carbide i ka radiation paʻakikī, ʻaʻole ia e hoʻohaʻahaʻa i nā waiwai uila o ka chip. ʻO ka palena kiʻekiʻe o ka wela hana o ke aniani (ʻoi aku ma mua o 6000C) hiki iā ʻoe ke hana i nā mea hilinaʻi loa no nā kūlana hana paʻakikī a me nā noi kūikawā. I kēia manawa, hiki iā mākou ke hoʻolako i nā ʻāpana liʻiliʻi 200mmSiC wafers me ka hoʻomau mau a loaʻa kahi waiwai i loko o ka hale kūʻai.

Hōʻike

| Helu | 'ikamu | Unite | Hana ʻia | Ka noiʻi | Dummy |

| 1. Nā ʻāpana | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | hoʻonohonoho ʻili | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Pilikino uila | |||||

| 2.1 | dopant | -- | n-ʻano Nitrogen | n-ʻano Nitrogen | n-ʻano Nitrogen |

| 2.2 | kūʻē | ohm ·cm | 0.015~0.025 | 0.01~0.03 | NA |

| 3. Parane mechanical | |||||

| 3.1 | anawaena | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | mānoanoa | μm | 500±25 | 500±25 | 500±25 |

| 3.3 | ʻO ke kuhi notch | ° | [1- 100]±5 | [1- 100]±5 | [1- 100]±5 |

| 3.4 | Hohonu Notch | mm | 1~1.5 | 1~1.5 | 1~1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Kakaka | μm | -25~25 | -45~45 | -65~65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Kūlana | |||||

| 4.1 | micropipe density | ea/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | mea metala | nā ʻātoma/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ea/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ea/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ea/cm2 | ≤7000 | ≤10000 | NA |

| 5. Ka maikaʻi maikaʻi | |||||

| 5.1 | mua | -- | Si | Si | Si |

| 5.2 | hoʻopau ʻili | -- | Si-maka CMP | Si-maka CMP | Si-maka CMP |

| 5.3 | ʻāpana | ea/wafer | ≤100 (nui≥0.3μm) | NA | NA |

| 5.4 | ʻūlū | ea/wafer | ≤5, Ka huina Length≤200mm | NA | NA |

| 5.5 | Kaulana chips/indents/cracks/stains/contamination | -- | ʻAʻohe | ʻAʻohe | NA |

| 5.6 | Nā wahi polytype | -- | ʻAʻohe | Wahi ≤10% | Wahi ≤30% |

| 5.7 | hoailona mua | -- | ʻAʻohe | ʻAʻohe | ʻAʻohe |

| 6. Ka maikaʻi hope | |||||

| 6.1 | hope hope | -- | C-maka MP | C-maka MP | C-maka MP |

| 6.2 | ʻūlū | mm | NA | NA | NA |

| 6.3 | lihi hemahema hope chips/indents | -- | ʻAʻohe | ʻAʻohe | NA |

| 6.4 | ʻōkalakala kua | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Kaha hope | -- | Notch | Notch | Notch |

| 7. Kaulana | |||||

| 7.1 | lihi | -- | Chamfer | Chamfer | Chamfer |

| 8. Pūʻolo | |||||

| 8.1 | kāʻei ʻana | -- | Epi-mākaukau me ka vacuum kāʻei ʻana | Epi-mākaukau me ka vacuum kāʻei ʻana | Epi-mākaukau me ka vacuum kāʻei ʻana |

| 8.2 | kāʻei ʻana | -- | Wafer nui hoʻopaʻa cassette | Wafer nui hoʻopaʻa cassette | Wafer nui hoʻopaʻa cassette |

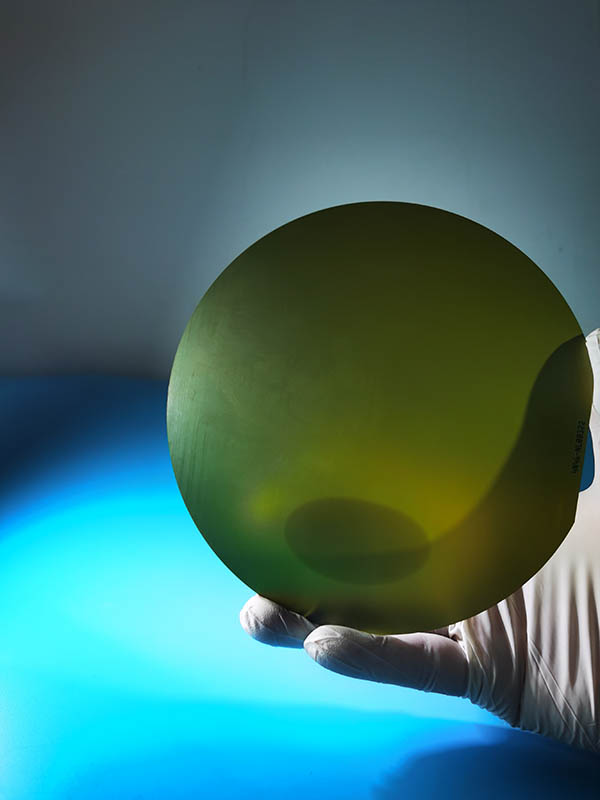

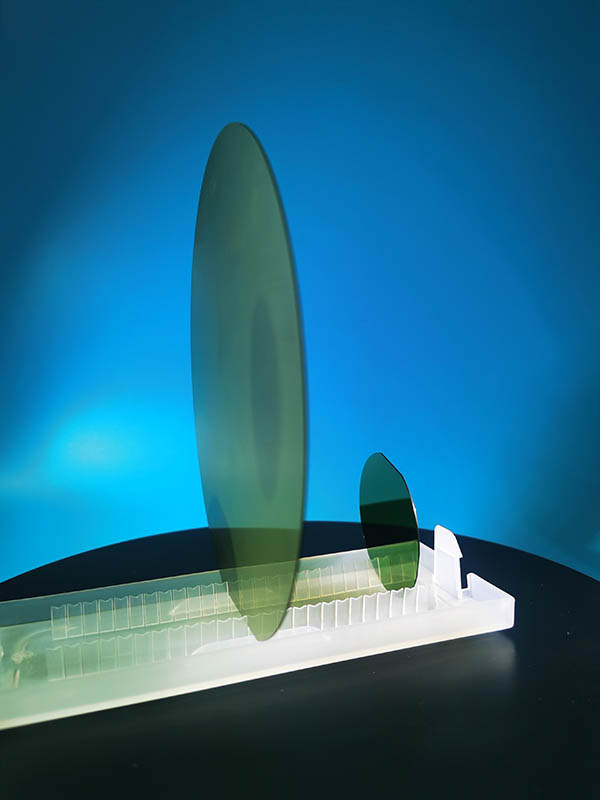

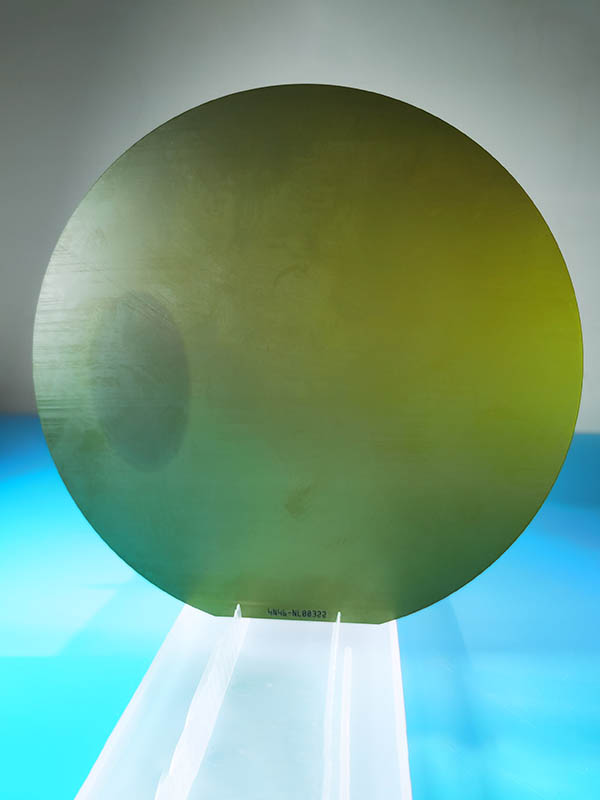

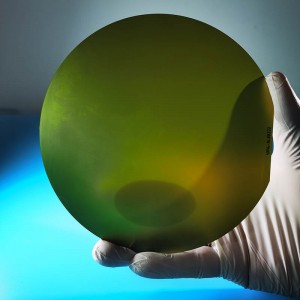

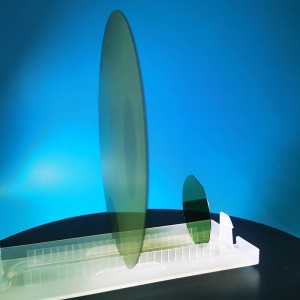

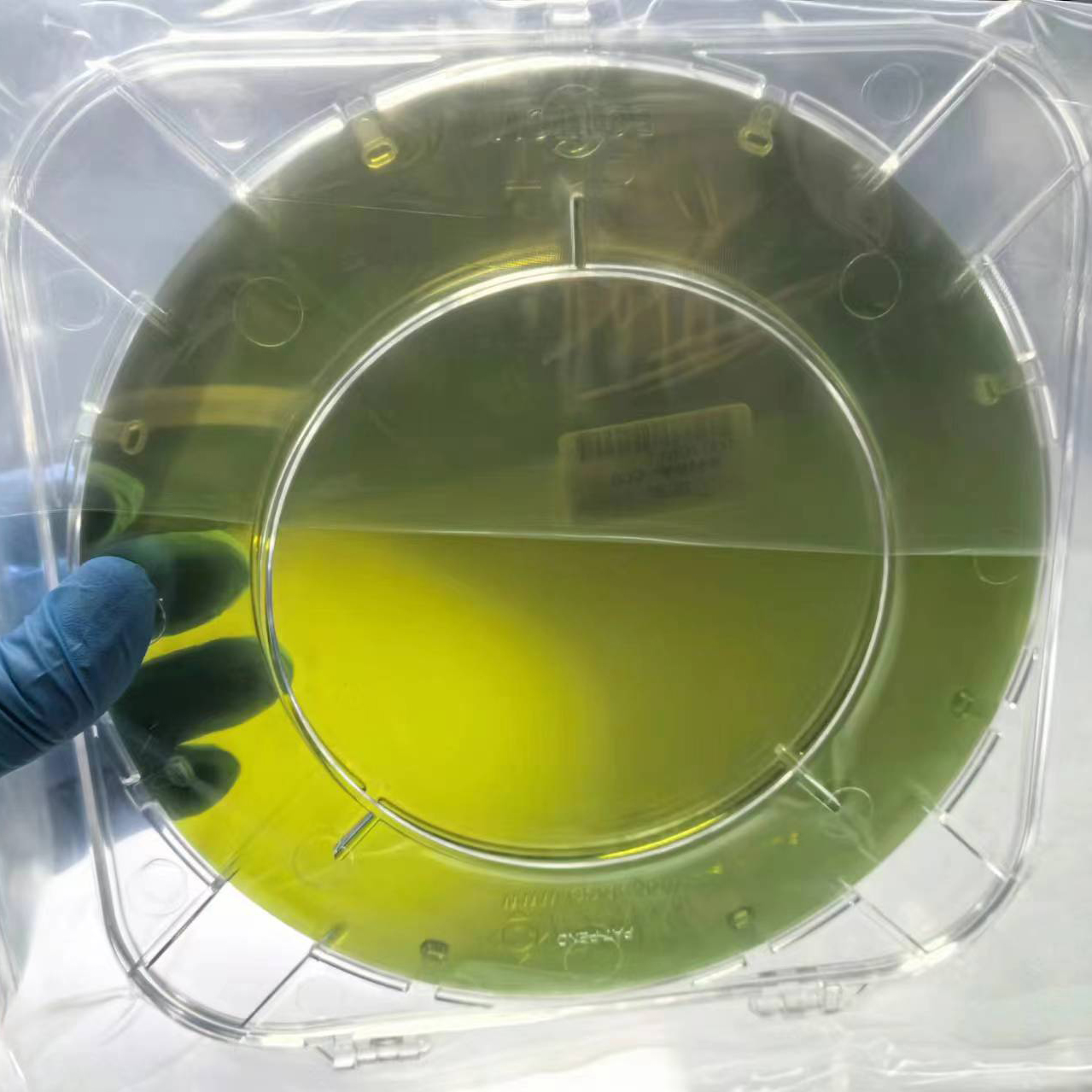

Kiʻi kikoʻī