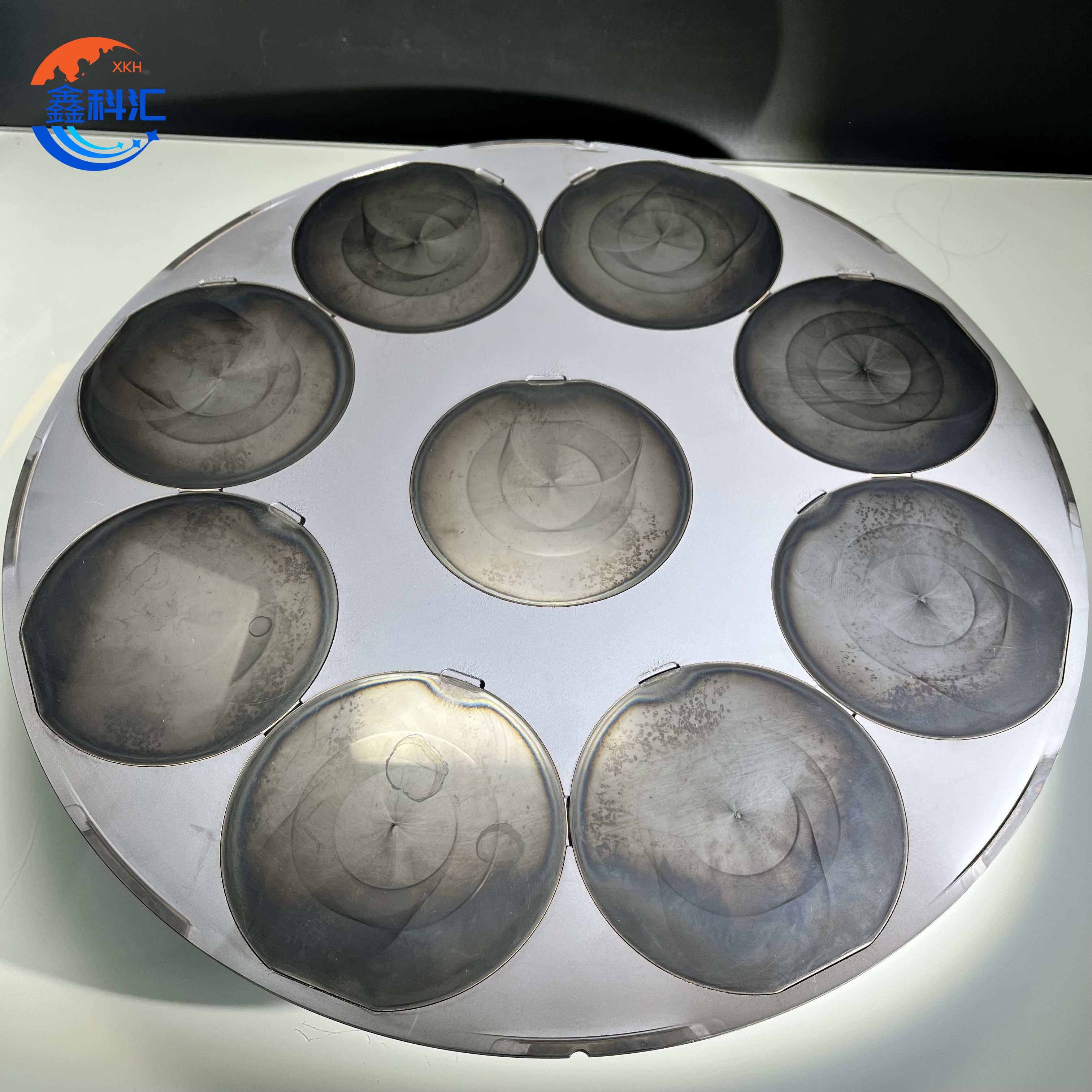

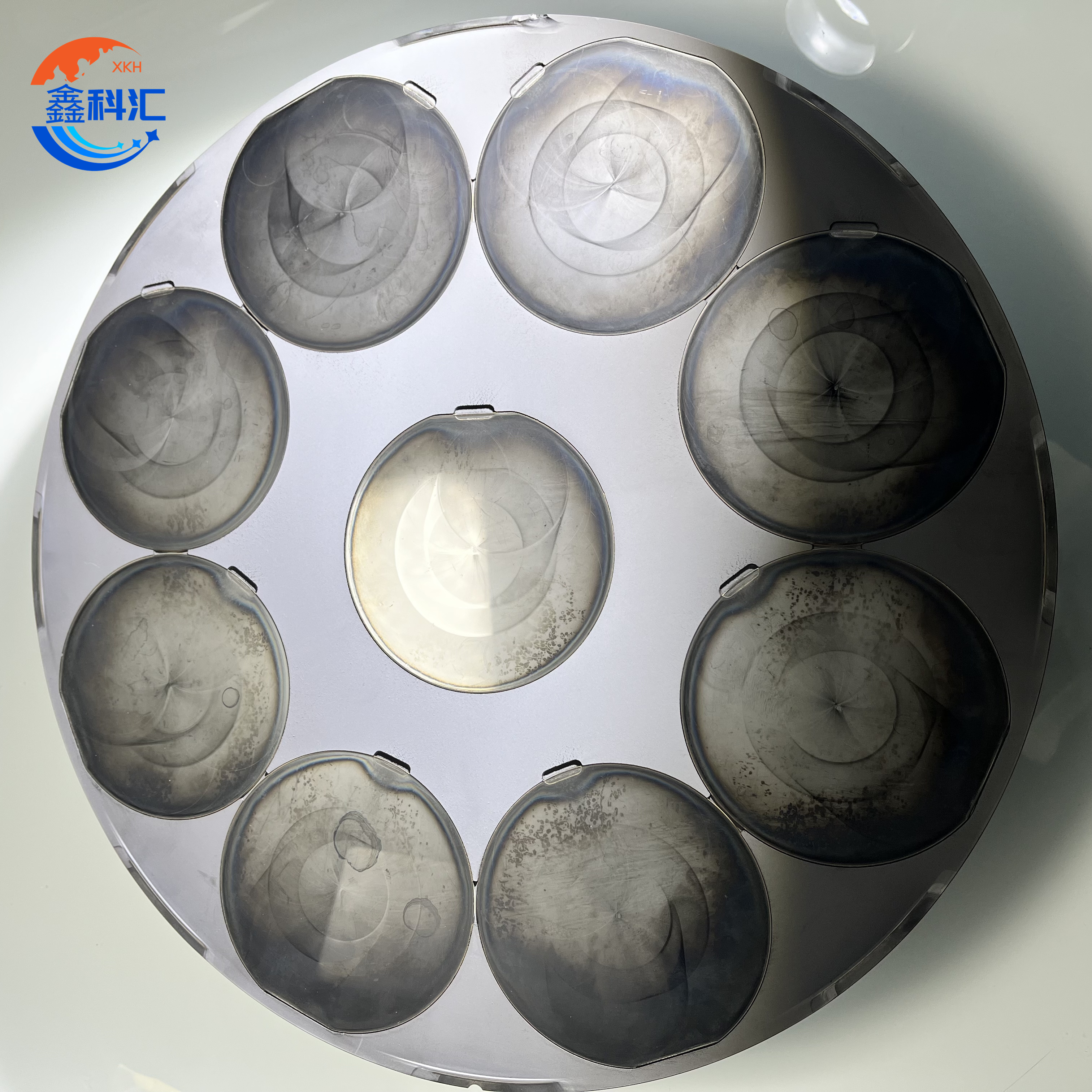

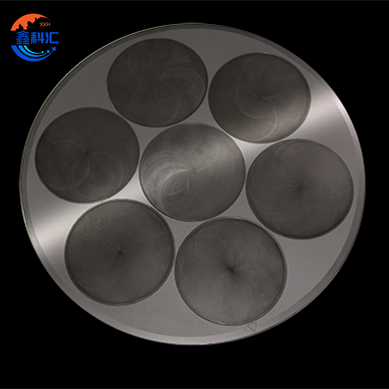

ʻO ka pā/pā pāpaʻi SiC no ka paʻa wafer 4 iniha 6 ʻīniha no ICP

ʻO ka pā kīla SiC Abstract

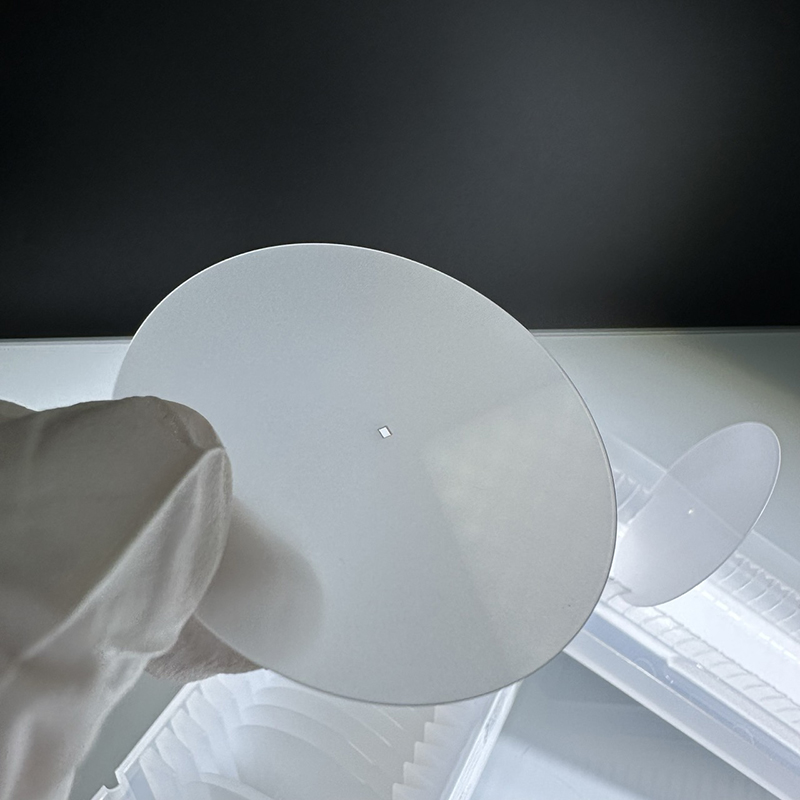

ʻO ka SiC ceramic plate kahi mea hana kiʻekiʻe i hana ʻia mai ka Silicon Carbide maʻemaʻe kiʻekiʻe, i hoʻolālā ʻia no ka hoʻohana ʻana i nā kaiapuni wela, kemika, a me ka mechanical. Kaulana ʻia no kona ʻano paʻakikī, ka hoʻoili wela, a me ka pale ʻana i ka corrosion, hoʻohana nui ʻia ka pā SiC ma ke ʻano he wafer carrier, susceptor, a i ʻole nā mea hana i loko o ka semiconductor, LED, photovoltaic, a me nā ʻoihana aerospace.

Me ke kūpaʻa wela koʻikoʻi a hiki i 1600 ° C a me ke kūpaʻa maikaʻi loa i nā kinoea reactive a me nā kaiapuni plasma, ʻo ka pā SiC e hōʻoia i ka hana maʻamau i ka wā etching kiʻekiʻe, deposition, a me nā kaʻina diffusion. ʻO kāna microstructure ʻeleʻele, ʻaʻole porous e hōʻemi i ka hoʻokumu ʻana i nā ʻāpana, e kūpono ia no nā noi hoʻomaʻemaʻe ultra-maʻemaʻe i loko o nā hoʻonohonoho maʻemaʻe.

ʻO ka hoʻohana ʻana i ka pā seramika SiC

1. Hana Hana Semiconductor

Hoʻohana maʻamau ʻia nā pā seramika SiC e like me nā mea lawe wafer, susceptors, a me nā papa pedestal i nā lako hana semiconductor e like me CVD (Chemical Vapor Deposition), PVD (Physical Vapor Deposition), a me nā ʻōnaehana etching. ʻO kā lākou hoʻoili wela maikaʻi a me ka hoʻonui haʻahaʻa haʻahaʻa e hiki ai iā lākou ke mālama i ka hāʻawi ʻana i ka mahana like ʻole, he mea koʻikoʻi no ka hana wafer kiʻekiʻe. ʻO ke kūʻē ʻana o SiC i nā kinoea corrosive a me nā plasmas e hōʻoia i ka lōʻihi i nā wahi paʻakikī, e kōkua ana i ka hōʻemi ʻana i ka palaka a me ka mālama ʻana i nā mea hana.

2. ʻOihana LED - ICP Etching

Ma ka ʻāpana hana LED, ʻo nā pā SiC nā mea nui i nā ʻōnaehana etching ICP (Inductively Coupled Plasma). Ke hana nei ma ke ʻano he mau wafer, hāʻawi lākou i kahi kahua paʻa a me ka wela e kākoʻo ai i nā wafers sapphire a i ʻole GaN i ka wā o ka hoʻoili ʻana i ka plasma. ʻO kā lākou kūpaʻa plasma maikaʻi loa, ka palahalaha o ka ʻili, a me ke kūpaʻa dimensional e kōkua i ka hōʻoia ʻana i ka pololei etching kiʻekiʻe a me ka like ʻole, e alakaʻi ana i ka hoʻonui ʻana a me ka hana ʻana o nā hāmeʻa i nā chips LED.

3. Photovoltaics (PV) a me Solar Energy

Hoʻohana pū ʻia nā pā ceramic SiC i ka hana ʻana o ka cell cell, ʻoiai i ka wā o ka sintering kiʻekiʻe a me nā hana annealing. ʻO kā lākou inertness i nā mahana kiʻekiʻe a me ka hiki ke pale aku i ka warping e hōʻoia i ka hana mau ʻana o nā wafer silika. Eia kekahi, he mea koʻikoʻi ko lākou haʻahaʻa haʻahaʻa no ka mālama ʻana i ka pono o nā cell photovoltaic.

ʻO SiC nā waiwai pā seramika

1. Ka ikaika a me ka paʻakikī o ka mīkini

Hōʻike nā papa seramika SiC i ka ikaika mechanical kiʻekiʻe loa, me ka ikaika flexural maʻamau ma mua o 400 MPa a me ka paʻakikī Vickers a hiki i ka 2000 HV. ʻO kēia ka mea e kūpaʻa nui ai lākou i ka lole mechanical, abrasion, a me ka deformation, e hōʻoiaʻiʻo ana i ka lōʻihi o ka lawelawe ʻana ma lalo o ka haʻahaʻa kiʻekiʻe a i ʻole ke kaʻa uila wela.

2. Kiekie Thermal Conductivity

Loaʻa i ka SiC ka wela wela maikaʻi (maʻamau 120–200 W/m·K), hiki iā ia ke puʻunaue like i ka wela ma kona ʻili. He mea koʻikoʻi kēia waiwai i nā kaʻina hana e like me ka wafer etching, deposition, a i ʻole sintering, kahi e pili pono ai ka like ʻana o ka mahana i ka hua a me ka maikaʻi.

3. ʻOi aku ka paʻa wela wela

Me kahi helu heheʻe kiʻekiʻe (2700 ° C) a me ka helu haʻahaʻa o ka hoʻonui wela (4.0 × 10⁻⁶ / K), mālama nā papa ceramic SiC i ka pololei o ka dimensional a me ka pololei o ke kūkulu ʻana ma lalo o ka hoʻomehana wikiwiki a me ka hoʻoilo. ʻO kēia ka mea i kūpono iā lākou no nā noi i nā umu wela wela, nā keʻena vacuum, a me nā wahi plasma.

| Nā Waiwai ʻenehana | ||||

| Papa kuhikuhi | Unite | Waiwai | ||

| Inoa Mea | ʻO ka hoʻoheheʻe Sintered Silicon Carbide | ʻO Silicon Carbide i hoʻopaʻa ʻole ʻia | ʻO Silicon Carbide i hana hou ʻia | |

| Huina | RBSiC | SSiC | R-SiC | |

| ʻAiʻi Nui | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

| Ikaika Flexural | MPa (kpsi) | 338(49) | 380(55) | 80-90 (20°C) 90-100(1400°C) |

| Ka ikaika hoʻopili | MPa (kpsi) | 1120(158) | 3970(560) | > 600 |

| ʻoʻoleʻa | Knoop | 2700 | 2800 | / |

| Haʻihaʻi Paʻa | MPa m1/2 | 4.5 | 4 | / |

| ʻO ka hoʻoili wela | W/mk | 95 | 120 | 23 |

| Coefficient o ka hoonui wela | 10-6.1/°C | 5 | 4 | 4.7 |

| Wela Kūikawā | Joule/g 0k | 0.8 | 0.67 | / |

| Max wela i ka ea | ℃ | 1200 | 1500 | 1600 |

| Elastic Modulus | Gpa | 360 | 410 | 240 |

Nīnauele Q&A ʻo SiC

Nīnau: He aha nā waiwai o ka pā carbide silika?

A: Ua ʻike ʻia nā papa Silicon carbide (SiC) no ko lākou ikaika kiʻekiʻe, paʻakikī, a me ke kūpaʻa wela. Hāʻawi lākou i ka conductivity thermal maikaʻi loa a me ka hoʻonui haʻahaʻa wela, e hōʻoiaʻiʻo ana i ka hana hilinaʻi ma lalo o nā wela wela. ʻO SiC hoʻi i kemika inert, kū'ē i nāʻakika, alkalis, a me nā kaiapuni plasma, i mea kūpono no ka semiconductor a me ka hana LED. ʻO kona ʻili paheʻe, hoʻoemi i ka hoʻokumu ʻana o nā ʻāpana, mālama i ka hoʻohālikelike ʻana o ka lumi maʻemaʻe. Hoʻohana nui ʻia nā pā SiC e like me nā mea lawe wafer, susceptors, a me nā mea kākoʻo i nā ʻenehana kiʻekiʻe a me nā corrosive ma waena o ka semiconductor, photovoltaic, a me nā ʻoihana aerospace.