4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer no MOS a i ʻole SBD

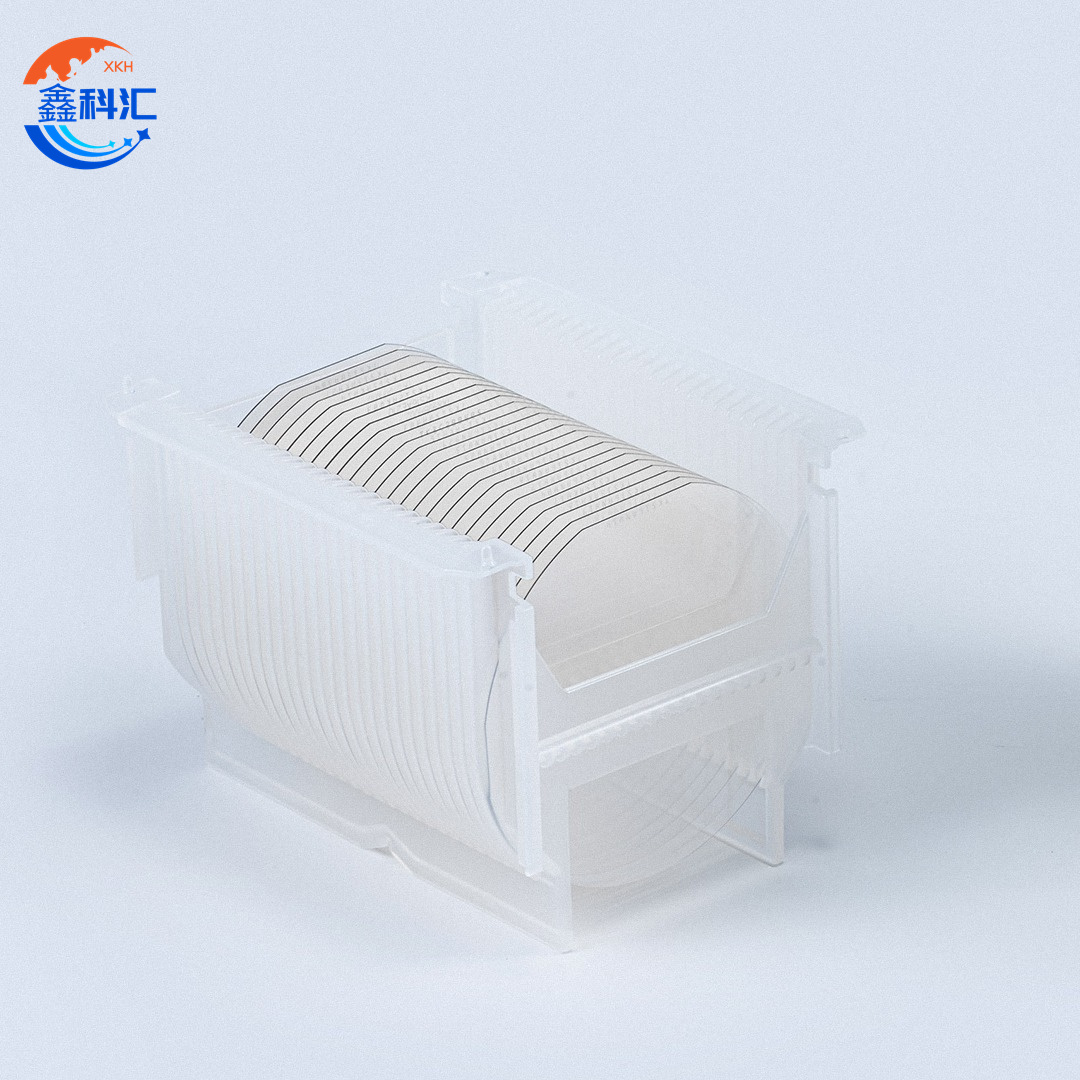

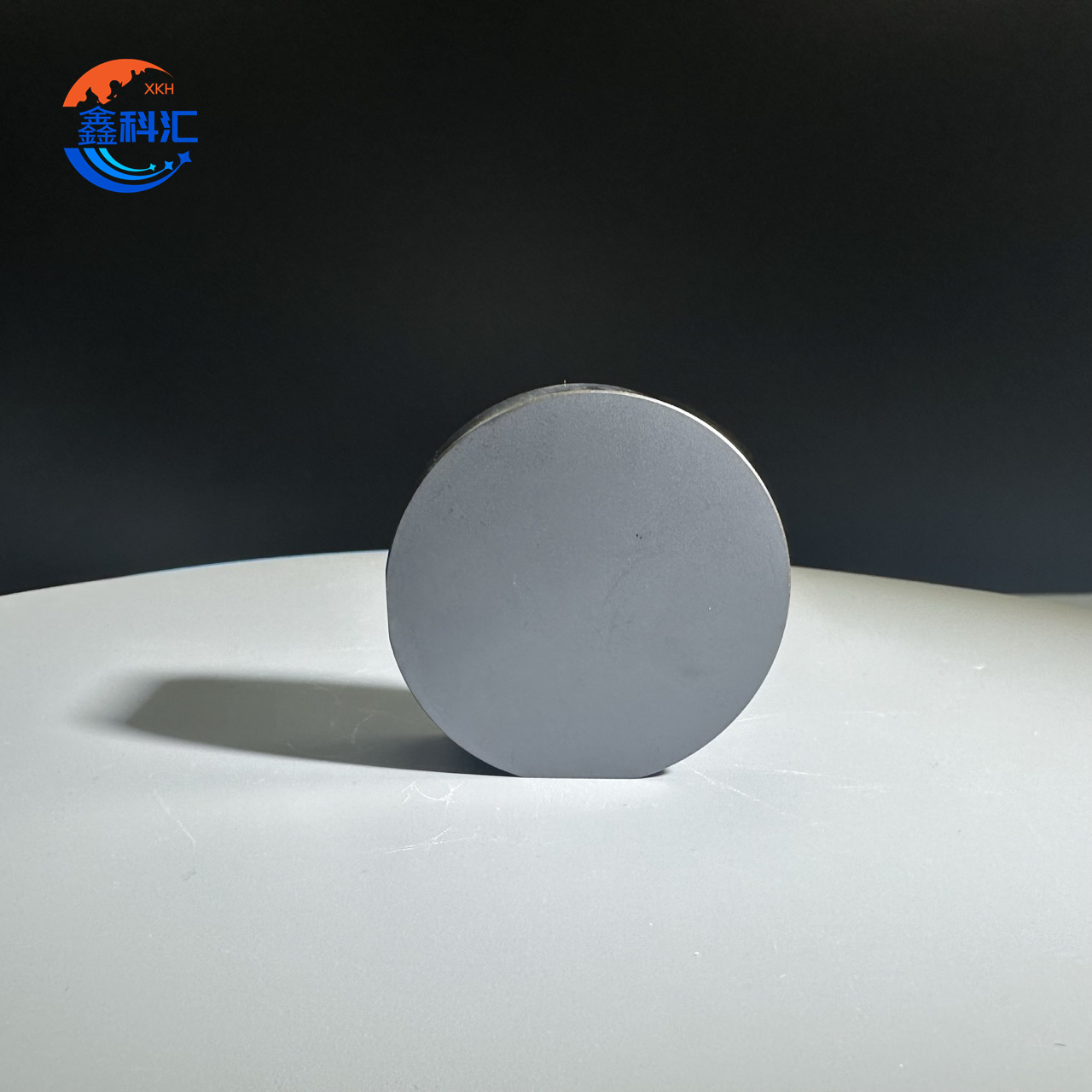

SiC Substrate SiC Epi-wafer pōkole

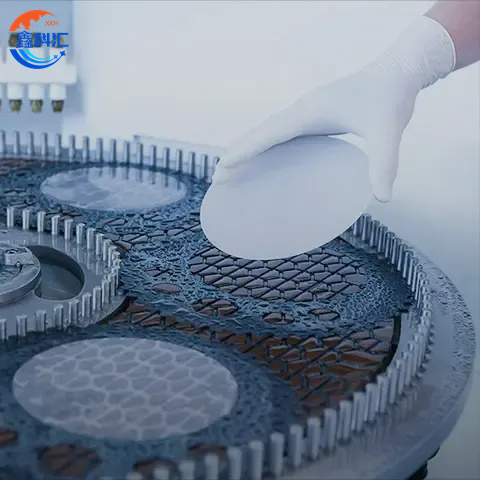

Hāʻawi mākou i kahi kōpili piha o nā substrates SiC kiʻekiʻe a me nā wafers sic i loko o nā polytypes a me nā profile doping-me 4H-N (n-type conductive), 4H-P (p-type conductive), 4H-HPSI (high-purity semi-insulating), a me 6H-P (p-type conductive)—i nā anawaena a pau, mai 6″ a hiki i ka 4″ a pau. 12″. Ma waho aʻe o nā substrate ʻole, hāʻawi kā mākou mau lawelawe ulu epi wafer i hoʻohui ʻia i nā wafers epitaxial (epi) me ka mānoanoa i hoʻopaʻa ʻia (1-20 µm), ka hoʻopaʻa ʻana i ka doping, a me nā density defect.

Loaʻa i kēlā me kēia wafer sic a me ka wafer epi i ka nānā ʻana i loko o ka laina (micropipe density <0.1 cm⁻², ʻeleʻele ʻili Ra <0.2 nm) a me ka hōʻike uila piha (CV, resistivity mapping) e hōʻoia i ka like ʻole o ka aniani a me ka hana. Inā hoʻohana ʻia no nā modula uila uila, nā amplifiers RF kiʻekiʻe, a i ʻole nā mea hana optoelectronic (LED, photodetectors), ʻo kā mākou SiC substrate a me nā laina huahana wafer epi e hāʻawi i ka hilinaʻi, ke kūpaʻa wela, a me ka ikaika haki i koi ʻia e nā noi koi nui loa.

Nā waiwai a me ka hoʻohana ʻana o ke ʻano SiC substrate 4H-N

-

4H-N SiC substrate Polytype (Hexagonal).

ʻO ka bandgap ākea o ~3.26 eV e hōʻoia i ka hana uila paʻa a me ka ikaika wela ma lalo o nā kūlana kiʻekiʻe a me nā kūlana kiʻekiʻe.

-

SiC substrateN-Kano Doping

ʻO ka doping nitrogen i hoʻopaʻa pono ʻia e hāʻawi mai i nā manaʻo lawe lawe mai 1 × 10¹⁶ a i 1 × 10¹⁹ cm⁻³ a me nā neʻe electron wela o ka lumi a hiki i ~900 cm²/V·s, e hōʻemi ana i nā poho conduction.

-

SiC substrateKū'ē ākea & Kaulike

Loaʻa ka laulā resistivity o 0.01–10 Ω·cm a me ka mānoanoa wafer o 350–650 µm me ka ± 5% ka hoʻomanawanui i ka doping a me ka mānoanoa-kūpono no ka hana ʻana i nā mea mana kiʻekiʻe.

-

SiC substrateʻAha-Haʻahaʻa Defect Density

Micropipe density < 0.1 cm⁻² a me basal-plane dislocation density < 500 cm⁻², e hāʻawi ana ma kahi o 99% o ka huahana a me ka ʻoi aku ka maikaʻi o ka kristal.

- SiC substrateKūʻokoʻa Thermal Conductivity

ʻO ka hana wela wela a hiki i ~370 W/m·K e hoʻomaʻamaʻa i ka wehe ʻana i ka wela, hoʻonui i ka hilinaʻi o ka hāmeʻa a me ka nui o ka mana.

-

SiC substrateNā noi i koho ʻia

ʻO nā MOSFET SiC, nā diodes Schottky, nā modula mana a me nā mea RF no nā kaʻa uila, nā mea hoʻohuli i ka lā, nā ʻoihana ʻenehana, nā ʻōnaehana traction, a me nā mākeke uila uila koi.

6inihi 4H-N ʻano SiC wafer kikoʻī | ||

| Waiwai | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Papa | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Anawaena | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| ʻAno poli | 4H | 4H |

| mānoanoa | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Kūlana Wafer | Koi aku: 4.0° a hiki i <1120> ± 0.5° | Koi aku: 4.0° a hiki i <1120> ± 0.5° |

| Micropipe Density | ≤ 0.2 knm² | ≤ 15 knm² |

| Kū'ē | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Kūlana Pāha mua | [10-10] ± 50° | [10-10] ± 50° |

| Ka lōʻihi pālahalaha | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Hoʻokuʻu Edge | 3 mm | 3 mm |

| LTV/TIV / Kakaka / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| ʻoʻoleʻa | Polani Ra ≤ 1 nm | Polani Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Nā Māwae ʻO Edge Ma ka Māmā ʻO ke Kiʻekiʻe | ʻO ka lōʻihi hui ≤ 20 mm ka lōʻihi hoʻokahi ≤ 2 mm | ʻO ka lōʻihi hui ≤ 20 mm ka lōʻihi hoʻokahi ≤ 2 mm |

| Nā Papa Hex Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 0.1% |

| Nā ʻāpana Polytype Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 3% |

| Hoʻokomo ʻia ʻo Carbon Visual | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 5% |

| ʻO ka ʻili o ka ʻili silikoni e ka māmā ikaika loa | Huina lōʻihi ≤ 1 wafer anawaena | |

| Nā Kiʻi Kiʻi Ma ka Māmā Kiʻekiʻe | ʻAʻole ʻae ʻia ≥ 0.2 mm laula a me ka hohonu | 7 ʻae ʻia, ≤ 1 mm kēlā me kēia |

| Hoʻokaʻawale ʻia ka Uila Uila | < 500 knm³ | < 500 knm³ |

| ʻO ka hoʻohaumia ʻana i ka ʻili o ka Silicon e ka māmā ikaika kiʻekiʻe | ||

| Hoʻopili ʻana | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi |

8inihi 4H-N ʻano SiC wafer kikoʻī | ||

| Waiwai | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Papa | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Anawaena | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| ʻAno poli | 4H | 4H |

| mānoanoa | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Kūlana Wafer | 4.0° i ka <110> ± 0.5° | 4.0° i ka <110> ± 0.5° |

| Micropipe Density | ≤ 0.2 knm² | ≤ 5 knm² |

| Kū'ē | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Kūlana Aliʻi | ||

| Hoʻokuʻu Edge | 3 mm | 3 mm |

| LTV/TIV / Kakaka / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| ʻoʻoleʻa | Polani Ra ≤ 1 nm | Polani Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Nā Māwae ʻO Edge Ma ka Māmā ʻO ke Kiʻekiʻe | ʻO ka lōʻihi hui ≤ 20 mm ka lōʻihi hoʻokahi ≤ 2 mm | ʻO ka lōʻihi hui ≤ 20 mm ka lōʻihi hoʻokahi ≤ 2 mm |

| Nā Papa Hex Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 0.1% |

| Nā ʻāpana Polytype Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 3% |

| Hoʻokomo ʻia ʻo Carbon Visual | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 5% |

| ʻO ka ʻili o ka ʻili silikoni e ka māmā ikaika loa | Huina lōʻihi ≤ 1 wafer anawaena | |

| Nā Kiʻi Kiʻi Ma ka Māmā Kiʻekiʻe | ʻAʻole ʻae ʻia ≥ 0.2 mm laula a me ka hohonu | 7 ʻae ʻia, ≤ 1 mm kēlā me kēia |

| Hoʻokaʻawale ʻia ka Uila Uila | < 500 knm³ | < 500 knm³ |

| ʻO ka hoʻohaumia ʻana i ka ʻili o ka Silicon e ka māmā ikaika kiʻekiʻe | ||

| Hoʻopili ʻana | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi |

ʻO 4H-SiC kahi mea hana kiʻekiʻe i hoʻohana ʻia no ka uila uila, nā polokalamu RF, a me nā noi wela kiʻekiʻe. ʻO ka "4H" e pili ana i ka hana aniani, he hexagonal, a ʻo ka "N" e hōʻike ana i kahi ʻano doping i hoʻohana ʻia no ka hoʻokō ʻana i ka hana o ka mea.

ʻO ka4H-SiCHoʻohana pinepine ʻia ke ʻano no:

Mea uila uila:Hoʻohana ʻia i nā mea like me nā diodes, MOSFET, a me IGBT no nā kaʻa uila uila, nā mīkini ʻenehana, a me nā ʻōnaehana ikehu hou.

ʻenehana 5G:Me ka koi o 5G no nā ʻāpana kiʻekiʻe a me nā mea kiʻekiʻe, hiki i ka SiC ke mālama i nā volta kiʻekiʻe a hana i nā wela kiʻekiʻe e kūpono ia no nā mea hoʻonui mana base station a me nā polokalamu RF.

Nā ʻōnaehana ikehu lā:He kūpono nā waiwai hoʻokele mana maikaʻi o SiC no nā mea hoʻohuli a me nā mea hoʻololi photovoltaic (mana solar).

Nā Kaʻa Uila (EV):Hoʻohana nui ʻia ʻo SiC i nā mana EV no ka hoʻololi ʻana i ka ikehu ʻoi aku ka maikaʻi, hoʻohaʻahaʻa haʻahaʻa wela, a me ka nui o ka mana.

SiC Substrate 4H Semi-Insulating 'ano waiwai a me ka noi

Nā waiwai:

-

Nā ʻenehana hoʻopaʻa haʻahaʻa ʻole micropipe: E hōʻoia i ka nele o nā micropipes, e hoʻomaikaʻi i ka maikaʻi o ka substrate.

-

Nā ʻenehana hoʻomalu monocrystalline: Hōʻoiaʻiʻo i hoʻokahi hale aniani no nā waiwai waiwai i hoʻonui ʻia.

-

Nā ʻenehana mana hoʻohui: Hoʻemi i ka loaʻa ʻana o nā haumia a i ʻole nā inclusions, e hōʻoia ana i kahi substrate maʻemaʻe.

-

Nā ʻenehana hoʻomalu resistivity: Hāʻawi i ka mana pololei o ka resistivity uila, he mea koʻikoʻi no ka hana ʻana o ka hāmeʻa.

-

Hoʻoponopono haumia a me nā ʻenehana hoʻomalu: Hoʻoponopono a hoʻopaʻa i ka hoʻokomoʻana i nā mea haumia e mālama i ka pono o ka substrate.

-

Nā ʻenehana hoʻomalu pae ʻanuʻu ākea: Hāʻawi i ka mana pololei ma luna o ka laula o ka ʻanuʻu, e hōʻoia ana i ka paʻa ʻana o ka substrate

6 ʻīniha 4H-semi SiC substrate kikoʻī | ||

| Waiwai | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Anawaena (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| ʻAno poli | 4H | 4H |

| mānoanoa (um) | 500 ± 15 | 500 ± 25 |

| Kūlana Wafer | Ma ke axis: ±0.0001° | Ma ke axis: ±0.05° |

| Micropipe Density | ≤ 15 knm-2 | ≤ 15 knm-2 |

| Kū'ē (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Kūlana Pāha mua | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Ka lōʻihi pālahalaha | Notch | Notch |

| Hoʻokuʻu ʻia ke kihi (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / kīʻaha / Warp | ≤ 3 µm | ≤ 3 µm |

| ʻoʻoleʻa | Polani Ra ≤ 1.5 µm | Polani Ra ≤ 1.5 µm |

| Nā Kiʻi Kiʻi Ma ka Māmā Kiʻekiʻe | ≤ 20 µm | ≤ 60 µm |

| ʻO nā pā wela e ka māmā ikaika kiʻekiʻe | Huina ≤ 0.05% | Huina ≤ 3% |

| Nā ʻāpana Polytype Ma ka Māmā Kiʻekiʻe | Hoʻokomo ʻia ʻo Carbon Carbon ≤ 0.05% | Huina ≤ 3% |

| ʻO ka ʻili o ka ʻili silikoni e ka māmā ikaika loa | ≤ 0.05% | Huina ≤ 4% |

| Nā Kiʻi Kiʻi Ma ka Māmā ʻImi Kiʻekiʻe (Lai) | ʻAʻole ʻae ʻia > 02 mm ka laula a me ka hohonu | ʻAʻole ʻae ʻia > 02 mm ka laula a me ka hohonu |

| ʻO ka hoʻomāhuahua ʻana o ka Screw kōkua | ≤ 500 µm | ≤ 500 µm |

| ʻO ka hoʻohaumia ʻana i ka ʻili o ka Silicon e ka māmā ikaika kiʻekiʻe | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Hoʻopili ʻana | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi |

4-Inch 4H-Semi Insulating SiC Substrate Specification

| ʻĀpana | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

|---|---|---|

| Na Waiwai Kino | ||

| Anawaena | 99.5 mm – 100.0 mm | 99.5 mm – 100.0 mm |

| ʻAno poli | 4H | 4H |

| mānoanoa | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Kūlana Wafer | Ma ke axis: <600h > 0.5° | Ma ke axis: <000h > 0.5° |

| Na Waiwai Uila | ||

| ʻOiʻa Micropipe (MPD) | ≤1 knm⁻² | ≤15 knm⁻² |

| Kū'ē | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Nā hoʻomanawanui Geometric | ||

| Kūlana Pāha mua | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Ka lōʻihi pālahalaha | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Ka lōʻihi pālahalaha lua | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Kūlana Pāpā lua | 90° CW mai Prime flat ± 5.0° (Si alo i luna) | 90° CW mai Prime flat ± 5.0° (Si alo i luna) |

| Hoʻokuʻu Edge | 3 mm | 3 mm |

| LTV / TTV / Kakaka / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| ʻAno ʻili | ||

| ʻO ʻAla ʻili (Polani Ra) | ≤1 nm | ≤1 nm |

| ʻO ka ʻākeke o ka ʻili (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Nā māwae ʻaoʻao (māmā Kiʻekiʻe) | ʻAʻole ʻae ʻia | ʻO ka lōʻihi kumulative ≥10 mm, hoʻokahi māwae ≤2 mm |

| Nā hemahema o ka pā hexagonal | ≤0.05% wahi hui | ≤0.1% ʻāpana hui |

| Nā Wahi Hoʻokomo Polytype | ʻAʻole ʻae ʻia | ≤1% ʻāpana hui |

| Hoʻokomo ʻia ʻo Carbon Visual | ≤0.05% wahi hui | ≤1% ʻāpana hui |

| Nā ʻili ʻili Silika | ʻAʻole ʻae ʻia | ≤1 wafer anawaena kumulative loa |

| ʻOpeʻa Kiki | ʻAʻole ʻae ʻia (≥0.2 mm laula/hohonu) | ≤5 mau ʻāpana (kekahi ≤1 mm) |

| ʻO ka hoʻohaumia ʻana o ka ʻili Silika | ʻAʻole i kuhikuhi ʻia | ʻAʻole i kuhikuhi ʻia |

| Hoʻopili ʻana | ||

| Hoʻopili ʻana | ʻO ka cassette multi-wafer a i ʻole ka pahu wafer hoʻokahi | ʻO ka cassette multi-wafer a i ʻole |

Noi:

ʻO kaSiC 4H Semi-Insulating substrateshoʻohana nui ʻia i nā mea uila uila kiʻekiʻe a me nā alapine kiʻekiʻe, ʻoi aku ka nui o kakahua RF. He mea koʻikoʻi kēia mau substrate no nā noi like ʻoleʻōnaehana kamaʻilio microwave, radar lāʻau i hoʻonohonoho ʻia, amea ʻike uila uila. ʻO kā lākou mau hiʻohiʻona wela kiʻekiʻe a me nā hiʻohiʻona uila maikaʻi loa e kūpono iā lākou no ke koi ʻana i nā noi i ka uila uila a me nā ʻōnaehana kamaʻilio.

SiC epi wafer 4H-N 'ano waiwai a me ka noi

ʻO SiC 4H-N ʻAno Epi Wafer Pono a me nā noi

Nā waiwai o SiC 4H-N Type Epi Wafer:

Huina Mea:

SiC (Silicon Carbide): ʻIke ʻia no kona paʻakikī koʻikoʻi, ka hoʻoili wela kiʻekiʻe, a me nā waiwai uila maikaʻi loa, kūpono ʻo SiC no nā mea uila hana kiʻekiʻe.

4H-SiC Polytype: Uaʻikeʻia ka polytype 4H-SiC no kona kūlana kiʻekiʻe a paʻa i nā polokalamu uila.

N-ʻano Doping: N-type doping (doped with nitrogen) hāʻawi i ka mobility electron maikaʻi loa, e kūpono ana iā SiC no nā noi kiʻekiʻe a me ka mana kiʻekiʻe.

Kiʻekiʻe Thermal Conductivity:

Loaʻa i nā wafers SiC ka conductivity thermal maikaʻi, maʻamau mai120–200 W/m·K, e ʻae iā lākou e hoʻokele pono i ka wela i nā mea mana kiʻekiʻe e like me nā transistors a me nā diodes.

ʻAkea Bandgap:

Me kahi bandgap o3.26 eV, Hiki i ka 4H-SiC ke hana i nā voltages kiʻekiʻe, nā alapine, a me nā mahana i hoʻohālikelikeʻia me nā mea hana maʻamau i hoʻokumuʻia i ka silicon, i mea e kūpono ai no ka hana kiʻekiʻe, kiʻekiʻe.

Nā Pono Uila:

ʻO ka mobility electron kiʻekiʻe a me ka conductivity o SiC i kūpono nouila uila, e hāʻawi ana i nā wikiwiki hoʻololi wikiwiki a me ka mana kiʻekiʻe o kēia manawa a me ka mana hoʻokele uila, e hopena i nā ʻōnaehana hoʻokele mana.

Kū'ē Mechanical a Kemika:

ʻO SiC kekahi o nā mea paʻakikī, ʻelua wale nō i ke daimana, a kūpaʻa loa i ka oxidation a me ka corrosion, e paʻa ai i nā kaiapuni paʻakikī.

Nā noi o SiC 4H-N Type Epi Wafer:

Mea uila uila:

Hoʻohana nui ʻia nā wafers epi ʻano SiC 4H-N mamana MOSFET, Nā IGBT, adiodesno ka meahoohuli manai nā ʻōnaehana e like menā mea hoʻohuli lā, nā kaʻa uila, aʻōnaehana mālama ikehu, hāʻawi i ka hana i hoʻonui ʻia a me ka ikaika o ka ikehu.

Nā Kaʻa Uila (EV):

In kaʻa uila powertrains, nā mea hoʻokele kaʻa, anā kahua hoʻouka, Kōkua ʻo SiC wafers e hoʻokō i ka ʻoi aku ka maikaʻi o ka pākaukau, ka hoʻopiʻi wikiwiki ʻana, a me ka hoʻomaikaʻi ʻana i ka hana ikehu holoʻokoʻa ma muli o ko lākou hiki ke mālama i ka mana kiʻekiʻe a me nā mahana.

Pūnaehana ikehu hou:

Nā mea hoʻohuli lā: Hoʻohana ʻia nā wafers SiC maʻōnaehana ikehu lāno ka hoʻololi ʻana i ka mana DC mai nā panela solar i AC, e hoʻonui ana i ka pono o ka ʻōnaehana holoʻokoʻa a me ka hana.

Nā Hulihu makani: Hoʻohana ʻia ka ʻenehana SiC maʻōnaehana hoʻokele makani, e hoʻonui ana i ka hana mana a me ka hoʻololi ʻana.

Aerospace a me ka pale:

He kūpono nā wafers SiC no ka hoʻohana ʻana mamea uila uilaapalapala noi koa, meʻōnaehana radarauila uila, kahi mea koʻikoʻi ka pale ʻana i ka radiation kiʻekiʻe a me ke kūpaʻa wela.

Nā noi no ka wela a me ke alapine kiʻekiʻe:

ʻOi aku ka maikaʻi o nā wafers SiCkiʻekiʻe-mehana uila, hoʻohana ʻia manā ʻenekini mokulele, mokulele mokulele, aʻōnaehana hoʻomehana ʻoihana, ke mālama nei lākou i ka hana ma nā kūlana wela loa. Eia kekahi, hiki i kā lākou bandgap ākea ke hoʻohana i lokonā noi alapine kiʻekiʻelikeNā lako RFakamaʻilio microwave.

| 6-inihi N-type epit axial kiko'ī | |||

| ʻĀpana | hui | Z-MOS | |

| ʻAno | Condutivity / Dopant | - | ʻAno N / Nitrogen |

| Papa Hoʻopaʻa | Mānoanoa Papa Hoʻopaʻa | um | 1 |

| Hoʻomanawanui Mānoanoa Layer | % | ±20% | |

| Hoʻopaʻa Layer Concentration | knm-3 | 1.00E+18 | |

| ʻO ka hoʻomanawanui hoʻopaʻa paʻa | % | ±20% | |

| 1st Epi Layer | Ka Manoanoa Epi | um | 11.5 |

| Kaulike Mānoanoa Epi Layer | % | ± 4% | |

| Epi Layers Thickness Tolerance((Spec- Max ,Min)/Spec) | % | ±5% | |

| Epi Layer Concentration | knm-3 | 1E 15~ 1E 18 | |

| Epi Layer Concentration Tolerance | % | 6% | |

| Epi Layer Concentration Uniformity (σ /mean) | % | ≤5% | |

| Epi Layer Concentrate Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| ʻAno Wafer Epitaixal | Kakaka | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Na ano nui | ʻAka lōʻihi | mm | ≤30mm |

| ʻOpeʻa Kiki | - | AOLE | |

| wehewehe hemahema | ≥97% (Ana me 2*2, Hoʻokomo nā hemahema pepehi: Aia nā hemahema Micropipe /Nā lua nui, Carrot, Triangular | ||

| Hoʻohaumia metala | nā ʻātoma/cm² | d f f ll i ≤5E10 ʻātoma/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Pūʻolo | Hoʻopili kikoʻī | pcs / pahu | cassette multi-wafer a i ʻole pahu wafer hoʻokahi |

| 8-inihi N-type epitaxial kiko'ī | |||

| ʻĀpana | hui | Z-MOS | |

| ʻAno | Condutivity / Dopant | - | ʻAno N / Nitrogen |

| Papa pale | Mānoanoa Papa Hoʻopaʻa | um | 1 |

| Hoʻomanawanui Mānoanoa Layer | % | ±20% | |

| Hoʻopaʻa Layer Concentration | knm-3 | 1.00E+18 | |

| ʻO ka hoʻomanawanui hoʻopaʻa paʻa | % | ±20% | |

| 1st Epi Layer | ʻAwelika mānoanoa o nā ʻāpana Epi | um | 8~ 12 |

| Kaulike mānoanoa o nā ʻāpana Epi (σ/mean) | % | ≤2.0 | |

| ʻO ka hoʻomanawanui mānoanoa o ka Epi ((Spec -Max,Min)/Spec) | % | ±6 | |

| Epi Layers Net Average Doping | knm-3 | 8E+15 ~2E+16 | |

| ʻO ka hoʻolikelike ʻana o nā ʻāpana Epi (σ/mean) | % | ≤5 | |

| Epi Layers Net DopingTolerance((Spec -Max, | % | ± 10.0 | |

| ʻAno Wafer Epitaixal | Mi )/S ) Warp | um | ≤50.0 |

| Kakaka | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Generala Nā hiʻohiʻona | Nā ʻōpala | - | Ka lōʻihi huila≤ 1/2Wafer anawaena |

| ʻOpeʻa Kiki | - | ≤2 chips, kēlā me kēia radius≤1.5mm | |

| Hoʻohaumia i nā metala ʻili | nā ʻātoma/cm2 | ≤5E10 ʻātoma/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Nānā hemahema | % | ≥ 96.0 (2X2 Defects me Micropipe /Nā lua nui, Kāroti, nā hemahema triangular, hāʻule iho, Linear/IGSF-s, BPD) | |

| Hoʻohaumia i nā metala ʻili | nā ʻātoma/cm2 | ≤5E10 ʻātoma/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Pūʻolo | Hoʻopili kikoʻī | - | cassette multi-wafer a i ʻole pahu wafer hoʻokahi |

Nīnau a SiC wafer

Q1: He aha nā pōmaikaʻi nui o ka hoʻohana ʻana i nā wafers SiC ma mua o nā wafer silicon kahiko i ka uila uila?

A1:

Hāʻawi nā wafers SiC i nā pono koʻikoʻi ma mua o nā wafers silicon (Si) maʻamau i ka uila uila, me:

ʻOi aku ka maikaʻi: Loaʻa iā SiC kahi bandgap ākea (3.26 eV) i hoʻohālikelike ʻia me ka silicon (1.1 eV), e ʻae ana i nā hāmeʻa e hana i nā voltage kiʻekiʻe, nā alapine, a me nā mahana. Ke alakaʻi nei kēia i ka haʻahaʻa haʻahaʻa o ka mana a me ka ʻoi aku ka maikaʻi o nā ʻōnaehana hoʻololi mana.

Kiʻekiʻe Thermal Conductivity: ʻOi aku ka kiʻekiʻe o ka hoʻoili wela o SiC ma mua o ka silika, e hiki ai i ka hoʻokuʻu ʻana i ka wela ma nā noi mana kiʻekiʻe, e hoʻomaikaʻi ai i ka hilinaʻi a me ke ola o nā mea mana.

ʻOi aku ka Voltage a me ka lawelawe ʻana i kēia manawa: Hiki i nā mea SiC ke mālama i nā volta kiʻekiʻe a me nā pae o kēia manawa, e kūpono ana iā lākou no nā noi mana kiʻekiʻe e like me nā kaʻa uila, nā ʻōnaehana ikehu hou, a me nā kaʻa kaʻa ʻoihana.

ʻOi aku ka wikiwiki o ka hoʻololi ʻana: Loaʻa i nā mea SiC nā mea hiki ke hoʻololi wikiwiki, e kōkua ana i ka hōʻemi ʻana i ka nalowale o ka ikehu a me ka nui o ka ʻōnaehana, e hoʻolilo iā lākou i mea kūpono no nā noi kiʻekiʻe.

Q2: He aha nā noi nui o nā wafers SiC i ka ʻoihana kaʻa?

A2:

I ka ʻoihana kaʻa, hoʻohana nui ʻia nā wafers SiC i:

Nā Kaʻa Uila (EV).: ʻO nā ʻāpana SiC likenā mea hoʻohuliamana MOSFEThoʻomaikaʻi i ka maikaʻi a me ka hana o nā kaʻa uila uila ma o ka hoʻololi ʻana i ka wikiwiki a me ka nui o ka ikehu kiʻekiʻe. Ke alakaʻi nei kēia i ka lōʻihi o ke ola pākaukau a ʻoi aku ka maikaʻi o ka hana kaʻa holoʻokoʻa.

Nā Luna Hoʻokele Papa: Kōkua ʻo SiC i ka hoʻomaikaʻi ʻana i ka pono o nā ʻōnaehana hoʻouka ma luna o ka papa ma o ka hiki ʻana i nā manawa hoʻopiʻi wikiwiki a me ka hoʻokele wela ʻoi aku ka maikaʻi, ʻo ia ka mea koʻikoʻi no nā EV e kākoʻo i nā kikowaena mana kiʻekiʻe.

Pūnaehana hoʻokele pākaukau (BMS): Hoʻonui ka ʻenehana SiC i ka pono oʻōnaehana hoʻokele pākaukau, e ʻae ana i ka hoʻoponopono uila ʻoi aku ka maikaʻi, ka mālama ʻana i ka mana kiʻekiʻe, a me ke ola pākaukau lōʻihi.

Nā mea hoʻololi DC-DC: Hoʻohana ʻia nā wafers SiC maNā mea hoʻololi DC-DCe hoʻololi i ka mana DC kiʻekiʻe-voltage i ka mana DC haʻahaʻa haʻahaʻa i ʻoi aku ka maikaʻi, ʻo ia ka mea koʻikoʻi i nā kaʻa uila e hoʻokele i ka mana mai ka pā a hiki i nā ʻāpana like ʻole o ke kaʻa.

ʻO ka hana maikaʻi loa o SiC i nā noi kiʻekiʻe-voltage, kiʻekiʻe-mehana, a me ka hana kiʻekiʻe e pono ai no ka hoʻololi ʻana o ka ʻoihana kaʻa i ka neʻe uila.

6inihi 4H-N ʻano SiC wafer kikoʻī | ||

| Waiwai | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Papa | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Anawaena | 149.5 mm – 150.0 mm | 149.5 mm – 150.0 mm |

| ʻAno poli | 4H | 4H |

| mānoanoa | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Kūlana Wafer | Koi aku: 4.0° a hiki i <1120> ± 0.5° | Koi aku: 4.0° a hiki i <1120> ± 0.5° |

| Micropipe Density | ≤ 0.2 knm² | ≤ 15 knm² |

| Kū'ē | 0.015 – 0.024 Ω·cm | 0.015 – 0.028 Ω·cm |

| Kūlana Pāha mua | [10-10] ± 50° | [10-10] ± 50° |

| Ka lōʻihi pālahalaha | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Hoʻokuʻu Edge | 3 mm | 3 mm |

| LTV/TIV / Kakaka / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| ʻoʻoleʻa | Polani Ra ≤ 1 nm | Polani Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Nā Māwae ʻO Edge Ma ka Māmā ʻO ke Kiʻekiʻe | ʻO ka lōʻihi hui ≤ 20 mm ka lōʻihi hoʻokahi ≤ 2 mm | ʻO ka lōʻihi hui ≤ 20 mm ka lōʻihi hoʻokahi ≤ 2 mm |

| Nā Papa Hex Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 0.1% |

| Nā ʻāpana Polytype Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 3% |

| Hoʻokomo ʻia ʻo Carbon Visual | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 5% |

| ʻO ka ʻili o ka ʻili silikoni e ka māmā ikaika loa | Huina lōʻihi ≤ 1 wafer anawaena | |

| Nā Kiʻi Kiʻi Ma ka Māmā Kiʻekiʻe | ʻAʻole ʻae ʻia ≥ 0.2 mm laula a me ka hohonu | 7 ʻae ʻia, ≤ 1 mm kēlā me kēia |

| Hoʻokaʻawale ʻia ka Uila Uila | < 500 knm³ | < 500 knm³ |

| ʻO ka hoʻohaumia ʻana i ka ʻili o ka Silicon e ka māmā ikaika kiʻekiʻe | ||

| Hoʻopili ʻana | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi |

8inihi 4H-N ʻano SiC wafer kikoʻī | ||

| Waiwai | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Papa | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Anawaena | 199.5 mm – 200.0 mm | 199.5 mm – 200.0 mm |

| ʻAno poli | 4H | 4H |

| mānoanoa | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Kūlana Wafer | 4.0° i ka <110> ± 0.5° | 4.0° i ka <110> ± 0.5° |

| Micropipe Density | ≤ 0.2 knm² | ≤ 5 knm² |

| Kū'ē | 0.015 – 0.025 Ω·cm | 0.015 – 0.028 Ω·cm |

| Kūlana Aliʻi | ||

| Hoʻokuʻu Edge | 3 mm | 3 mm |

| LTV/TIV / Kakaka / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| ʻoʻoleʻa | Polani Ra ≤ 1 nm | Polani Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Nā Māwae ʻO Edge Ma ka Māmā ʻO ke Kiʻekiʻe | ʻO ka lōʻihi hui ≤ 20 mm ka lōʻihi hoʻokahi ≤ 2 mm | ʻO ka lōʻihi hui ≤ 20 mm ka lōʻihi hoʻokahi ≤ 2 mm |

| Nā Papa Hex Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 0.1% |

| Nā ʻāpana Polytype Ma ka Māmā Kiʻekiʻe | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 3% |

| Hoʻokomo ʻia ʻo Carbon Visual | ʻĀpana hui ≤ 0.05% | ʻĀpana hui ≤ 5% |

| ʻO ka ʻili o ka ʻili silikoni e ka māmā ikaika loa | Huina lōʻihi ≤ 1 wafer anawaena | |

| Nā Kiʻi Kiʻi Ma ka Māmā Kiʻekiʻe | ʻAʻole ʻae ʻia ≥ 0.2 mm laula a me ka hohonu | 7 ʻae ʻia, ≤ 1 mm kēlā me kēia |

| Hoʻokaʻawale ʻia ka Uila Uila | < 500 knm³ | < 500 knm³ |

| ʻO ka hoʻohaumia ʻana i ka ʻili o ka Silicon e ka māmā ikaika kiʻekiʻe | ||

| Hoʻopili ʻana | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi |

6 ʻīniha 4H-semi SiC substrate kikoʻī | ||

| Waiwai | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

| Anawaena (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| ʻAno poli | 4H | 4H |

| mānoanoa (um) | 500 ± 15 | 500 ± 25 |

| Kūlana Wafer | Ma ke axis: ±0.0001° | Ma ke axis: ±0.05° |

| Micropipe Density | ≤ 15 knm-2 | ≤ 15 knm-2 |

| Kū'ē (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Kūlana Pāha mua | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Ka lōʻihi pālahalaha | Notch | Notch |

| Hoʻokuʻu ʻia ke kihi (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / kīʻaha / Warp | ≤ 3 µm | ≤ 3 µm |

| ʻoʻoleʻa | Polani Ra ≤ 1.5 µm | Polani Ra ≤ 1.5 µm |

| Nā Kiʻi Kiʻi Ma ka Māmā Kiʻekiʻe | ≤ 20 µm | ≤ 60 µm |

| ʻO nā pā wela e ka māmā ikaika kiʻekiʻe | Huina ≤ 0.05% | Huina ≤ 3% |

| Nā ʻāpana Polytype Ma ka Māmā Kiʻekiʻe | Hoʻokomo ʻia ʻo Carbon Carbon ≤ 0.05% | Huina ≤ 3% |

| ʻO ka ʻili o ka ʻili silikoni e ka māmā ikaika loa | ≤ 0.05% | Huina ≤ 4% |

| Nā Kiʻi Kiʻi Ma ka Māmā ʻImi Kiʻekiʻe (Lai) | ʻAʻole ʻae ʻia > 02 mm ka laula a me ka hohonu | ʻAʻole ʻae ʻia > 02 mm ka laula a me ka hohonu |

| ʻO ka hoʻomāhuahua ʻana o ka Screw kōkua | ≤ 500 µm | ≤ 500 µm |

| ʻO ka hoʻohaumia ʻana i ka ʻili o ka Silicon e ka māmā ikaika kiʻekiʻe | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Hoʻopili ʻana | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi | ʻO ka pahu wafer nui a i ʻole ka pahu wafer hoʻokahi |

4-Inch 4H-Semi Insulating SiC Substrate Specification

| ʻĀpana | ʻAʻohe papa hana MPD (Z Grade) | Papa Dummy (Papa D) |

|---|---|---|

| Na Waiwai Kino | ||

| Anawaena | 99.5 mm – 100.0 mm | 99.5 mm – 100.0 mm |

| ʻAno poli | 4H | 4H |

| mānoanoa | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Kūlana Wafer | Ma ke axis: <600h > 0.5° | Ma ke axis: <000h > 0.5° |

| Na Waiwai Uila | ||

| ʻOiʻa Micropipe (MPD) | ≤1 knm⁻² | ≤15 knm⁻² |

| Kū'ē | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Nā hoʻomanawanui Geometric | ||

| Kūlana Pāha mua | (0×10) ± 5.0° | (0×10) ± 5.0° |

| Ka lōʻihi pālahalaha | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Ka lōʻihi pālahalaha lua | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Kūlana Pāpā lua | 90° CW mai Prime flat ± 5.0° (Si alo i luna) | 90° CW mai Prime flat ± 5.0° (Si alo i luna) |

| Hoʻokuʻu Edge | 3 mm | 3 mm |

| LTV / TTV / Kakaka / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| ʻAno ʻili | ||

| ʻO ʻAla ʻili (Polani Ra) | ≤1 nm | ≤1 nm |

| ʻO ka ʻākeke o ka ʻili (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Nā māwae ʻaoʻao (māmā Kiʻekiʻe) | ʻAʻole ʻae ʻia | ʻO ka lōʻihi kumulative ≥10 mm, hoʻokahi māwae ≤2 mm |

| Nā hemahema o ka pā hexagonal | ≤0.05% wahi hui | ≤0.1% ʻāpana hui |

| Nā Wahi Hoʻokomo Polytype | ʻAʻole ʻae ʻia | ≤1% ʻāpana hui |

| Hoʻokomo ʻia ʻo Carbon Visual | ≤0.05% wahi hui | ≤1% ʻāpana hui |

| Nā ʻili ʻili Silika | ʻAʻole ʻae ʻia | ≤1 wafer anawaena kumulative loa |

| ʻOpeʻa Kiki | ʻAʻole ʻae ʻia (≥0.2 mm laula/hohonu) | ≤5 mau ʻāpana (kekahi ≤1 mm) |

| ʻO ka hoʻohaumia ʻana o ka ʻili Silika | ʻAʻole i kuhikuhi ʻia | ʻAʻole i kuhikuhi ʻia |

| Hoʻopili ʻana | ||

| Hoʻopili ʻana | ʻO ka cassette multi-wafer a i ʻole ka pahu wafer hoʻokahi | ʻO ka cassette multi-wafer a i ʻole |

| 6-inihi N-type epit axial kiko'ī | |||

| ʻĀpana | hui | Z-MOS | |

| ʻAno | Condutivity / Dopant | - | ʻAno N / Nitrogen |

| Papa Hoʻopaʻa | Mānoanoa Papa Hoʻopaʻa | um | 1 |

| Hoʻomanawanui Mānoanoa Layer | % | ±20% | |

| Hoʻopaʻa Layer Concentration | knm-3 | 1.00E+18 | |

| ʻO ka hoʻomanawanui hoʻopaʻa paʻa | % | ±20% | |

| 1st Epi Layer | Ka Manoanoa Epi | um | 11.5 |

| Kaulike Mānoanoa Epi Layer | % | ± 4% | |

| Epi Layers Thickness Tolerance((Spec- Max ,Min)/Spec) | % | ±5% | |

| Epi Layer Concentration | knm-3 | 1E 15~ 1E 18 | |

| Epi Layer Concentration Tolerance | % | 6% | |

| Epi Layer Concentration Uniformity (σ /mean) | % | ≤5% | |

| Epi Layer Concentrate Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| ʻAno Wafer Epitaixal | Kakaka | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Na ano nui | ʻAka lōʻihi | mm | ≤30mm |

| ʻOpeʻa Kiki | - | AOLE | |

| wehewehe hemahema | ≥97% (Ana me 2*2, Hoʻokomo nā hemahema pepehi: Aia nā hemahema Micropipe /Nā lua nui, Carrot, Triangular | ||

| Hoʻohaumia metala | nā ʻātoma/cm² | d f f ll i ≤5E10 ʻātoma/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Pūʻolo | Hoʻopili kikoʻī | pcs / pahu | cassette multi-wafer a i ʻole pahu wafer hoʻokahi |

| 8-inihi N-type epitaxial kiko'ī | |||

| ʻĀpana | hui | Z-MOS | |

| ʻAno | Condutivity / Dopant | - | ʻAno N / Nitrogen |

| Papa pale | Mānoanoa Papa Hoʻopaʻa | um | 1 |

| Hoʻomanawanui Mānoanoa Layer | % | ±20% | |

| Hoʻopaʻa Layer Concentration | knm-3 | 1.00E+18 | |

| ʻO ka hoʻomanawanui hoʻopaʻa paʻa | % | ±20% | |

| 1st Epi Layer | ʻAwelika mānoanoa o nā ʻāpana Epi | um | 8~ 12 |

| Kaulike mānoanoa o nā ʻāpana Epi (σ/mean) | % | ≤2.0 | |

| ʻO ka hoʻomanawanui mānoanoa o ka Epi ((Spec -Max,Min)/Spec) | % | ±6 | |

| Epi Layers Net Average Doping | knm-3 | 8E+15 ~2E+16 | |

| ʻO ka hoʻolikelike ʻana o nā ʻāpana Epi (σ/mean) | % | ≤5 | |

| Epi Layers Net DopingTolerance((Spec -Max, | % | ± 10.0 | |

| ʻAno Wafer Epitaixal | Mi )/S ) Warp | um | ≤50.0 |

| Kakaka | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| Generala Nā hiʻohiʻona | Nā ʻōpala | - | Ka lōʻihi huila≤ 1/2Wafer anawaena |

| ʻOpeʻa Kiki | - | ≤2 chips, kēlā me kēia radius≤1.5mm | |

| Hoʻohaumia i nā metala ʻili | nā ʻātoma/cm2 | ≤5E10 ʻātoma/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Nānā hemahema | % | ≥ 96.0 (2X2 Defects me Micropipe /Nā lua nui, Kāroti, nā hemahema triangular, hāʻule iho, Linear/IGSF-s, BPD) | |

| Hoʻohaumia i nā metala ʻili | nā ʻātoma/cm2 | ≤5E10 ʻātoma/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Pūʻolo | Hoʻopili kikoʻī | - | cassette multi-wafer a i ʻole pahu wafer hoʻokahi |

Q1: He aha nā pōmaikaʻi nui o ka hoʻohana ʻana i nā wafers SiC ma mua o nā wafer silicon kahiko i ka uila uila?

A1:

Hāʻawi nā wafers SiC i nā pono koʻikoʻi ma mua o nā wafers silicon (Si) maʻamau i ka uila uila, me:

ʻOi aku ka maikaʻi: Loaʻa iā SiC kahi bandgap ākea (3.26 eV) i hoʻohālikelike ʻia me ka silicon (1.1 eV), e ʻae ana i nā hāmeʻa e hana i nā voltage kiʻekiʻe, nā alapine, a me nā mahana. Ke alakaʻi nei kēia i ka haʻahaʻa haʻahaʻa o ka mana a me ka ʻoi aku ka maikaʻi o nā ʻōnaehana hoʻololi mana.

Kiʻekiʻe Thermal Conductivity: ʻOi aku ka kiʻekiʻe o ka hoʻoili wela o SiC ma mua o ka silika, e hiki ai i ka hoʻokuʻu ʻana i ka wela ma nā noi mana kiʻekiʻe, e hoʻomaikaʻi ai i ka hilinaʻi a me ke ola o nā mea mana.

ʻOi aku ka Voltage a me ka lawelawe ʻana i kēia manawa: Hiki i nā mea SiC ke mālama i nā volta kiʻekiʻe a me nā pae o kēia manawa, e kūpono ana iā lākou no nā noi mana kiʻekiʻe e like me nā kaʻa uila, nā ʻōnaehana ikehu hou, a me nā kaʻa kaʻa ʻoihana.

ʻOi aku ka wikiwiki o ka hoʻololi ʻana: Loaʻa i nā mea SiC nā mea hiki ke hoʻololi wikiwiki, e kōkua ana i ka hōʻemi ʻana i ka nalowale o ka ikehu a me ka nui o ka ʻōnaehana, e hoʻolilo iā lākou i mea kūpono no nā noi kiʻekiʻe.

Q2: He aha nā noi nui o nā wafers SiC i ka ʻoihana kaʻa?

A2:

I ka ʻoihana kaʻa, hoʻohana nui ʻia nā wafers SiC i:

Nā Kaʻa Uila (EV).: ʻO nā ʻāpana SiC likenā mea hoʻohuliamana MOSFEThoʻomaikaʻi i ka maikaʻi a me ka hana o nā kaʻa uila uila ma o ka hoʻololi ʻana i ka wikiwiki a me ka nui o ka ikehu kiʻekiʻe. Ke alakaʻi nei kēia i ka lōʻihi o ke ola pākaukau a ʻoi aku ka maikaʻi o ka hana kaʻa holoʻokoʻa.

Nā Luna Hoʻokele Papa: Kōkua ʻo SiC i ka hoʻomaikaʻi ʻana i ka pono o nā ʻōnaehana hoʻouka ma luna o ka papa ma o ka hiki ʻana i nā manawa hoʻopiʻi wikiwiki a me ka hoʻokele wela ʻoi aku ka maikaʻi, ʻo ia ka mea koʻikoʻi no nā EV e kākoʻo i nā kikowaena mana kiʻekiʻe.

Pūnaehana hoʻokele pākaukau (BMS): Hoʻonui ka ʻenehana SiC i ka pono oʻōnaehana hoʻokele pākaukau, e ʻae ana i ka hoʻoponopono uila ʻoi aku ka maikaʻi, ka mālama ʻana i ka mana kiʻekiʻe, a me ke ola pākaukau lōʻihi.

Nā mea hoʻololi DC-DC: Hoʻohana ʻia nā wafers SiC maNā mea hoʻololi DC-DCe hoʻololi i ka mana DC kiʻekiʻe-voltage i ka mana DC haʻahaʻa haʻahaʻa i ʻoi aku ka maikaʻi, ʻo ia ka mea koʻikoʻi i nā kaʻa uila e hoʻokele i ka mana mai ka pā a hiki i nā ʻāpana like ʻole o ke kaʻa.

ʻO ka hana maikaʻi loa o SiC i nā noi kiʻekiʻe-voltage, kiʻekiʻe-mehana, a me ka hana kiʻekiʻe e pono ai no ka hoʻololi ʻana o ka ʻoihana kaʻa i ka neʻe uila.