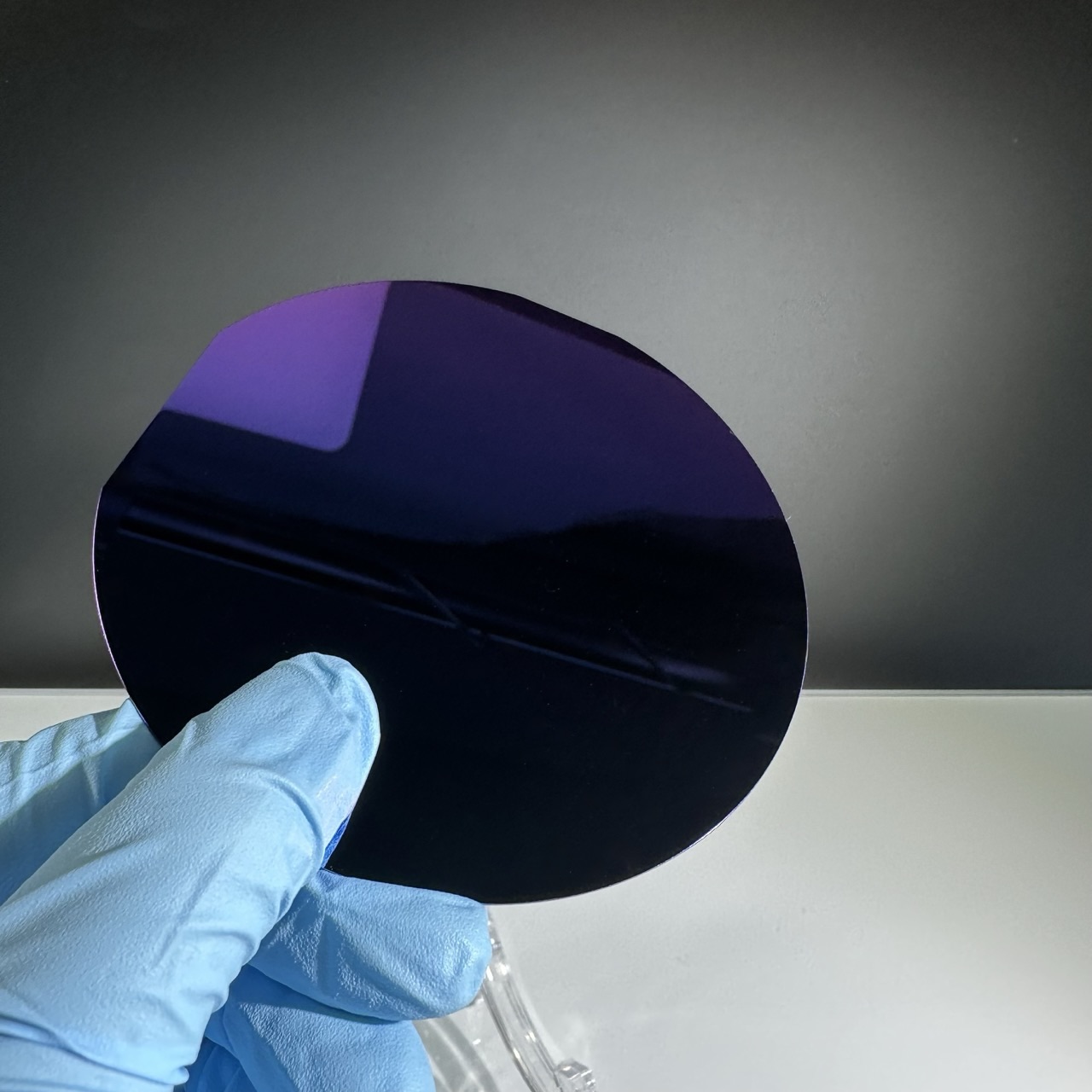

Silicon Dioxide wafer SiO2 wafer mānoanoa Polished, Prime and Test Grade

Hoʻolauna i ka pahu wafer

| Huahana | ʻO ka wai wela wela (Si+SiO2). |

| Hana Hana | LPCVD |

| Hoʻomaʻamaʻa ʻili | SSP/DSP |

| Anawaena | 2 ʻīniha / 3 ʻīniha / 4 ʻīniha / 5 ʻīniha/ 6 ʻīniha |

| ʻAno | ʻAno P / ʻano N |

| Oxidation Layer mānoanoa | 100nm ~1000nm |

| Kūlana | <100> <111> |

| ʻAiʻa uila | 0.001-25000(Ω•cm) |

| Palapala noi | Hoʻohana ʻia no ka lawe ʻana i ka laʻana o ka radiation synchrotron, PVD/CVD coating ma ke ʻano he substrate, magnetron sputtering growth sample, XRD, SEM,ʻO ka ikaika ʻātoma, spectroscopy infrared, spectroscopy fluorescence a me nā substrates hoʻāʻo ʻē aʻe, nā substrate ulu epitaxial molecular beam, ka nānā ʻana X-ray o nā semiconductor crystalline. |

ʻO nā wafers silicon oxide he kiʻiʻoniʻoni silicon dioxide i ulu ma luna o ka ʻili o nā wafers silicon ma o ka oxygen a i ʻole ka wai wai ma nā wela kiʻekiʻe (800 ° C ~ 1150 ° C) me ka hoʻohana ʻana i ke kaʻina hana hoʻoheheʻe wela me nā mea ʻenehana puʻupuʻu umu. ʻO ka mānoanoa o ke kaʻina hana mai 50 nanometers a 2 microns, ʻo ke kaʻina hana a hiki i 1100 degere Celsius, ua māhele ʻia ke ʻano ulu i ka "oxygen mākū" a me ka "oxygen maloʻo" ʻelua ʻano. ʻO ka Thermal Oxide kahi ʻāpana oxide "ulu", ʻoi aku ka kiʻekiʻe o ka like ʻana, ʻoi aku ka maikaʻi o ka densification a me ka ikaika dielectric kiʻekiʻe ma mua o ka CVD i waiho ʻia i nā papa oxide, e hopena i ka maikaʻi.

ʻOkiona ʻokiʻoki maloʻo

Hoʻopili ka silikoni me ka oxygen a ke neʻe mau nei ka papa okisa i ka papa substrate. Pono e hana ʻia ka oxidation maloʻo ma nā mahana mai 850 a 1200 ° C, me ka haʻahaʻa o ka ulu ʻana, a hiki ke hoʻohana ʻia no ka ulu ʻana o ka puka insulated MOS. ʻOi aku ka maikaʻi o ka oxidation maloʻo ma mua o ka oxidation pulu ke koi ʻia kahi papa kiʻekiʻe kiʻekiʻe, ultra-thin silicon oxide. Mākaukau maloʻo oxidation: 15nm ~ 300nm.

2. Wet Oxidation

Ke hoʻohana nei kēia ʻano i ka mahu wai e hana i kahi papa oxide ma ke komo ʻana i ka paipu umu ma lalo o nā kūlana wela kiʻekiʻe. ʻOi aku ka maikaʻi o ka densification o ka wai oxygen oxidation ma mua o ka maloʻo oxygen oxidation, akā i ka hoʻohālikelike ʻia me ka oxygen oxidation maloʻo kona pono ʻoi aku ka kiʻekiʻe o ka ulu ʻana, kūpono no ka ulu ʻana o ka kiʻiʻoniʻoni 500nm. ʻO ka hiki ke hoʻoheheʻe wai: 500nm ~ 2µm.

ʻO AEMD's atmospheric pressure oxidation furnace tube he Czech horizontal furnace tube, kahi i hōʻike ʻia e ke kūpaʻa kaʻina hana kiʻekiʻe, ka like ʻana o ke kiʻiʻoniʻoni maikaʻi a me ka mana ʻoi aku ka maikaʻi. Hiki i ke kinikini oxide furnace paipu ke hana a hiki i 50 wafers no kēlā me kēia paipu, me ka maikaʻi loa intra- a inter-wafers uniformity.

Kiʻi kikoʻī