Lako Wafer Thinning No 4 Iniha-12 Iniha Sapphire/SiC/Si Wafers Processing

Kumu Hana

Ke hana nei ke kaʻina hana hoʻoheheʻe wafer ma ʻekolu mau pae:

ʻO Rough Grinding: ʻO ka huila daimana (ka nui o ka grit 200–500 μm) e wehe i 50–150 μm o nā mea ma 3000–5000 rpm e hoʻemi koke i ka mānoanoa.

ʻO ka wili maikaʻi: ʻO ka huila ʻoi aku ka maikaʻi (ka nui o ka grit 1-50 μm) e hoʻemi i ka mānoanoa i 20-50 μm ma <1 μm/s e hōʻemi i ka pōʻino o lalo.

Polishing (CMP): Hoʻopau ka slurry kemika-mechanical i ke koena pōʻino, loaʻa iā Ra <0.1 nm.

Nā mea kūpono

Silicon (Si): Maʻamau no nā wafers CMOS, hoʻoemi ʻia i 25 μm no ka hoʻopaʻa ʻana 3D.

Silicon Carbide (SiC): Pono i nā huila daimana kūikawā (80% diamond concentration) no ka paʻa wela.

Sapphire (Al₂O₃): Hoʻemi ʻia i 50 μm no nā noi LED UV.

Nā ʻĀpana Pūnaehana Koʻikoʻi

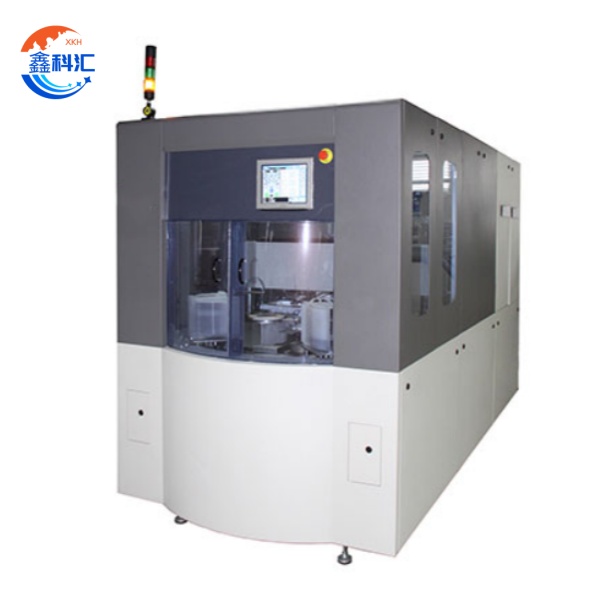

1. Pūnaehana wili

ʻElua-Axis Grinder: Hoʻohui i ka wili koʻikoʻi / maikaʻi i kahi kahua hoʻokahi, e hōʻemi ana i ka manawa pōʻai e 40%.

ʻAerostatic Spindle: 0-6000 rpm ka wikiwiki me ka <0.5 μm radial runout.

2. Pūnaehana Hoʻohana Wafer

ʻO Vacuum Chuck: > 50 N ka ikaika paʻa me ka ± 0.1 μm kūlana pololei.

ʻO Robotic Arm: Lawe i nā wafers 4-12-inihi ma 100 mm/s.

3. Pūnaehana hoʻomalu

Laser Interferometry: Ka nānā ʻana i ka mānoanoa manawa maoli (hoʻonā 0.01 μm).

AI-Driven Feedforward: Manaʻo i ka lole huila a hoʻoponopono maʻalahi i nā ʻāpana.

4. Hoomaemae & Hoomaemae

Ultrasonic Cleaning: Wehe i nā ʻāpana> 0.5 μm me 99.9% pono.

ʻO ka wai Deionized: Hoʻolili ka wafer a hiki i ka <5°C ma luna o ka ambient.

Pono Pono

1. Ka Papa Kiʻekiʻe-Kiʻekiʻe: TTV (Ka huina mānoanoa o ka mānoanoa) <0.5 μm, WTW (Ma loko o ka Wafer Thickness Variation) <1 μm.

2. Hoʻohui Hoʻohui Nui: Hoʻohui i ka wili, CMP, a me ka etching plasma i hoʻokahi mīkini.

3. Mea Pilikino:

Silika: Hoʻemi ʻia ka mānoanoa mai 775 μm a i 25 μm.

SiC: Loaʻa iā <2 μm TTV no nā noi RF.

Nā Wafers Doped: Wafers InP-doped Phosphorus me <5% resistivity drift.

4. Smart Automation: ʻO ka hoʻohui MES e hōʻemi i ka hewa kanaka e 70%.

5. ʻO ka ikaika o ka ikehu: 30% haʻahaʻa i ka hoʻohana ʻana i ka mana ma o ka regenerative braking.

Nā noi nui

1. Hoʻopili kiʻekiʻe

• Nā IC 3D: Hiki i ka hoʻoheheʻe ʻia ʻana o ka wafer ke hoʻopaʻa pololei i nā ʻāpana logic/memory chips (e laʻa, HBM stacks), loaʻa iā 10x kiʻekiʻe bandwidth a me 50% hoʻemi ʻia ka hoʻohana ʻana i ka mana i hoʻohālikelike ʻia me 2.5D solutions. Kākoʻo nā mea hana i ka hoʻopili hybrid a me ka hoʻohui ʻana o TSV (Through-Silicon Via), koʻikoʻi no nā kaʻina AI/ML e koi ana i <10 μm interconnect pitch. No ka laʻana, 12-inch wafers thinned i 25 μm e ʻae i ka hoʻopaʻa ʻana i 8+ papa ʻoiai e mālama ana i <1.5% warpage, pono no nā ʻōnaehana LiDAR automotive.

• Fan-Out Packaging: Ma ka ho'ēmiʻana i ka mānoanoa wafer i 30 μm, ua pōkole ka lōʻihi o ka pilina e 50%, e hōʻemi ana i ka lohi hōʻailona (<0.2 ps / mm) a hiki i ka 0.4 mm ultra-thin chiplets no nā SoCs mobile. Hoʻohana ke kaʻina hana i nā algorithms wili i uku ʻia e pale i ka warpage (> 50 μm TTV control), e hōʻoia i ka hilinaʻi i nā noi RF kiʻekiʻe.

2. Mea uila uila

• Nā Module IGBT: ʻO ka hoʻoemi ʻana i ka 50 μm e hōʻemi i ka pale ʻana i ka wela i <0.5 ° C / W, hiki i ka 1200V SiC MOSFET ke hana ma 200 ° C junction wela. Hoʻohana kā mākou mau mea hana i ka wili ʻana i nā ʻāpana he nui (kokoke: 46 μm grit → maikaʻi: 4 μm grit) e hoʻopau i ka pōʻino o lalo, e loaʻa ana ma kahi o 10,000 mau pōʻai o ka hilinaʻi kaʻa uila. He mea koʻikoʻi kēia no nā mea hoʻohuli EV, kahi e hoʻomaikaʻi ai nā wafers SiC 10 μm-mānoanoa i ka wikiwiki hoʻololi e 30% .

• Nā Mea Mana Mana GaN-on-SiC: Hoʻonui ka wafer thinning i 80 μm i ka neʻe electron (μ > 2000 cm²/V·s) no 650V GaN HEMTs, e hōʻemi ana i nā poho conduction e 18%. Ke hoʻohana nei ke kaʻina hana i ka dicing kōkua laser e pale aku i ka haki ʻana i ka wā o ka lahilahi, e loaʻa ana <5 μm edge chipping no RF power amplifiers.

3. Optoelectronics

• Nā LED GaN-on-SiC: 50 μm sapphire substrates e hoʻonui i ka pono o ka laweʻana i ka māmā (LEE) i ka 85% (vs. 65% no nā wafers 150 μm) ma ka hoʻemiʻana i ka paʻi kiʻi photon. ʻO ka mana TTV ultra-haʻahaʻa o kā mākou mea hana (<0.3 μm) e hōʻoia i ka hoʻokuʻu ʻana o ka LED ma waena o nā wafers 12-inch, koʻikoʻi no nā hōʻike Micro-LED e koi ana i ka like ʻana o ka lōʻihi hawewe he 100nm.

• Silicon Photonics: 25μm-mānoanoa silicon wafers hiki i 3 dB/cm haʻahaʻa hoʻolaha poho i loko o waveguides, pono no 1.6 Tbps optical transceivers. Hoʻopili ke kaʻina hana i ka hoʻomaʻamaʻa CMP e hōʻemi i ka roughness o ka ʻili i Ra <0.1 nm, e hoʻonui ana i ka maikaʻi o ka hui ʻana e 40%.

4. Nā mea ʻike MEMS

• Accelerometers: 25 μm silicon wafers loaʻa SNR>85 dB (vs. 75 dB no 50 μm wafers) ma ka hoʻonui ʻana i ka proof-mass displacement sensitivity. Hoʻopiʻi kā mākou ʻōnaehana wili ʻelua-axis no nā gradients koʻikoʻi, e hōʻoia ana <0.5% ka neʻe ʻana o ka naʻau ma luna o -40°C a i 125°C. Loaʻa nā noi i ka ʻike ulia kaʻa a me ka nānā ʻana i ka neʻe AR/VR.

• Nā Manaʻo Paʻi: ʻO ka hoʻoemi ʻana a hiki i 40 μm hiki i ka 0–300 mau pae ana ʻana me <0.1% FS hysteresis. Ke hoʻohana nei i ka hoʻopaʻa ʻana i ka manawa (nā mea lawe aniani), pale ke kaʻina hana i ka haʻihaʻi ʻana i ka wafer i ka wā etching hope, e loaʻa ana <1 μm overpressure tolerance no nā mea ʻike IoT ʻoihana.

• Hoʻonaʻauao ʻenehana: Hoʻohui kā mākou mea hoʻoheheʻe wafer i ka wili mīkini, CMP, a me ka etching plasma no ka hoʻoponopono ʻana i nā pilikia waiwai like ʻole (Si, SiC, Sapphire). No ka laʻana, koi ʻo GaN-on-SiC i ka wili hybrid (nā huila daimana + plasma) e hoʻohālikelike i ka paʻakikī a me ka hoʻonui ʻana i ka wela, aʻo nā mea ʻike MEMS e koi ana i ka ʻeleʻele sub-5 nm ma o CMP polishing.

• Ka hopena o ka ʻoihana: Ma ka ʻae ʻana i nā wafers ʻoi aku ka lahilahi, ʻoi aku ka maikaʻi o ka hana, ua hoʻokau kēia ʻenehana i nā mea hou i nā chips AI, 5G mmWave modules, a me nā mea uila maʻalahi, me nā ʻae TTV <0.1 μm no nā hōʻike foldable a <0.5 μm no nā mea ʻike LiDAR kaʻa.

Nā lawelawe a XKH

1. Hoʻoponopono i hoʻopilikino ʻia

Nā hoʻonohonoho hiki ke hoʻonui ʻia: 4-12-ʻīniha hoʻolālā keʻena me ka hoʻouka ʻana a me ka wehe ʻana.

Kākoʻo Doping: ʻO nā ʻōkuhi maʻamau no nā kristal Er/Yb-doped a me nā wafers InP/GaAs.

2. Kākoʻo Hope-to-End

Ke Kaʻina Hana Hana: Holo ka hoʻāʻo manuahi me ka optimization.

Hoʻomaʻamaʻa honua: Nā papa hana ʻenehana i kēlā me kēia makahiki e pili ana i ka mālama a me ka hoʻoponopono pilikia.

3. ʻO ka hana ʻana i nā mea he nui

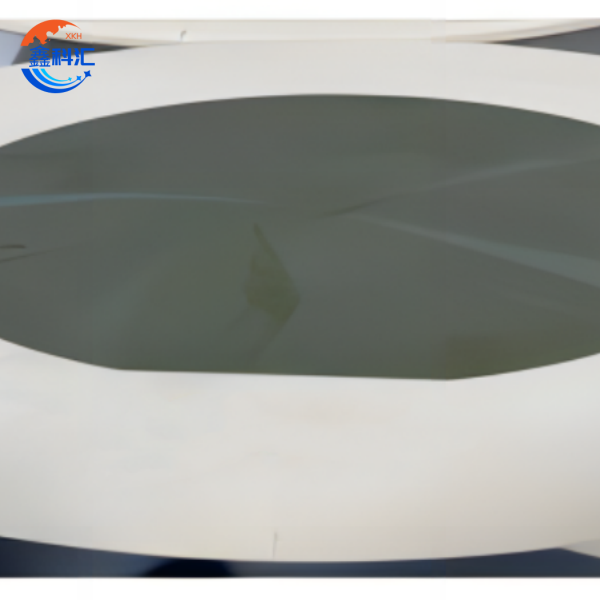

ʻO SiC: ʻO ka wafer lahilahi a hiki i 100 μm me Ra <0.1 nm.

Sapphire: 50μm mānoanoa no nā puka makani laser UV (ka hoʻouna ʻana> 92%@200 nm).

4. Nā lawelawe hoʻohui waiwai

Mea hoʻohana ʻia: nā huila daimana (2000+ wafers / ola) a me nā slurries CMP.

Ka hopena

Hāʻawi kēia mea hana hoʻoheheʻe wafer i ka pololei alakaʻi alakaʻi ʻoihana, multi-material versatility, a me ka automation akamai, e lilo ia i mea nui no ka hoʻohui ʻana 3D a me ka uila uila. ʻO nā lawelawe piha XKH—mai ka hana maʻamau a hiki i ka hoʻoponopono ʻana—e hōʻoia i ka loaʻa ʻana o nā mea kūʻai i ka maikaʻi o ke kumukūʻai a me ka maikaʻi o ka hana ma ka hana semiconductor.